Method and system for planning trigonometric function expression curve with continuous jerk and chip mounter

A curve planning and jerk technology, applied in the field of control, can solve problems such as response jitter, shock vibration, and complex design process, and achieve the effects of ensuring stable time, reducing motion impact, and fewer calculation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

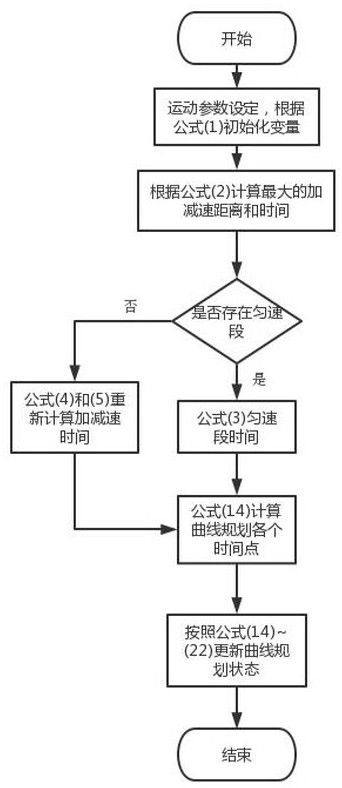

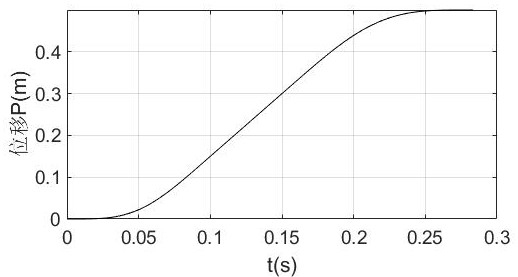

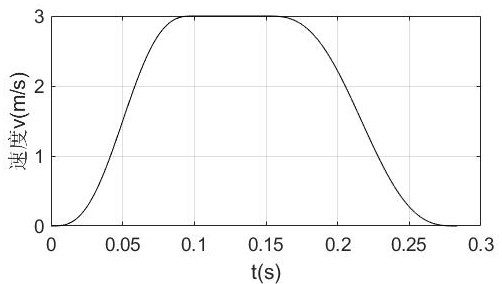

[0134] Initialize curve planning parameters, assuming the starting location ,target location , Set the maximum speed value to , Average acceleration value According to the formula (1) initialization exercise parameters

[0135] Essence

[0136] Soften factor = 1, acceleration coefficient = 1.5, that is, the 7 -stage curve at this time is the symmetrical curve, and the maximum acceleration is 1.5 times the average acceleration. According to the formula, you can calculate the acceleration time, deceleration time, acceleration distance and deceleration distance to

[0137] Essence

[0138] because + According to the formula (3), the distance and time of running at a constant speed are

[0139] Essence

[0140] Then press = 1.5, obtained according to the formula (6)-(14)

[0141] Essence

[0142] time from Start, to For time interval, accumulate The entire curve planning process is updated in accordance with the formula (15)- (22) to update the real-time increase ...

Embodiment 2

[0145] Set the same initialization parameter as real -time example 1, assuming the starting location ,target location , Set the maximum speed value to , Average acceleration value According to public formula (1) initialization motion parameters

[0146] Essence

[0147] Soften factor = 0.75, acceleration coefficient = 1.5, that is, the 7 -stage curve at this time is asymmetric curve, the average acceleration of the deceleration section is 0.75 times the acceleration segment, and the maximum acceleration is 1.5 times the average acceleration. According to the formula, the acceleration time, deceleration time, acceleration distance and deceleration distance can be

[0148] Essence

[0149] because + According to the formula (3), the distance and time of running at a constant speed are

[0150] Essence

[0151] Then press = 1.5, obtained according to the formula (6)-(14)

[0152] Essence

[0153] time from Start, to For time interval, accumulate The entire curve ...

Embodiment 3

[0156] Set the same initialization parameters as embodiment 1 and 2, assuming the starting location ,target location , Set the maximum speed value to , Average acceleration value According to public formula (1) initialization motion parameters

[0157] Essence

[0158] Soften factor = 0.75, acceleration coefficient = 2, at this time, the curve plan can be considered as a 5 -stage curve that does not have a uniform speed. The average acceleration of the deceleration section is 0.75 times the acceleration segment, and the maximum acceleration is 2 times the average acceleration. According to the formula, you can calculate the acceleration time, deceleration time, acceleration distance and deceleration distance to

[0159] Essence

[0160] because + According to the formula (3), the distance and time of running at a constant speed are

[0161] Essence

[0162] Then press = 2, obtain according to the formula (6)-(14)

[0163] Essence

[0164] time from Start, to Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com