Spliced industrial scene application robot training practice platform

A scenario application, robot technology, applied in the direction of instruments, manipulators, manufacturing tools, etc., can solve the problems of inflexible equipment composition, low participation, single training content, etc., to achieve the effect of facilitating product testing and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, the content of the present invention is described in further detail:

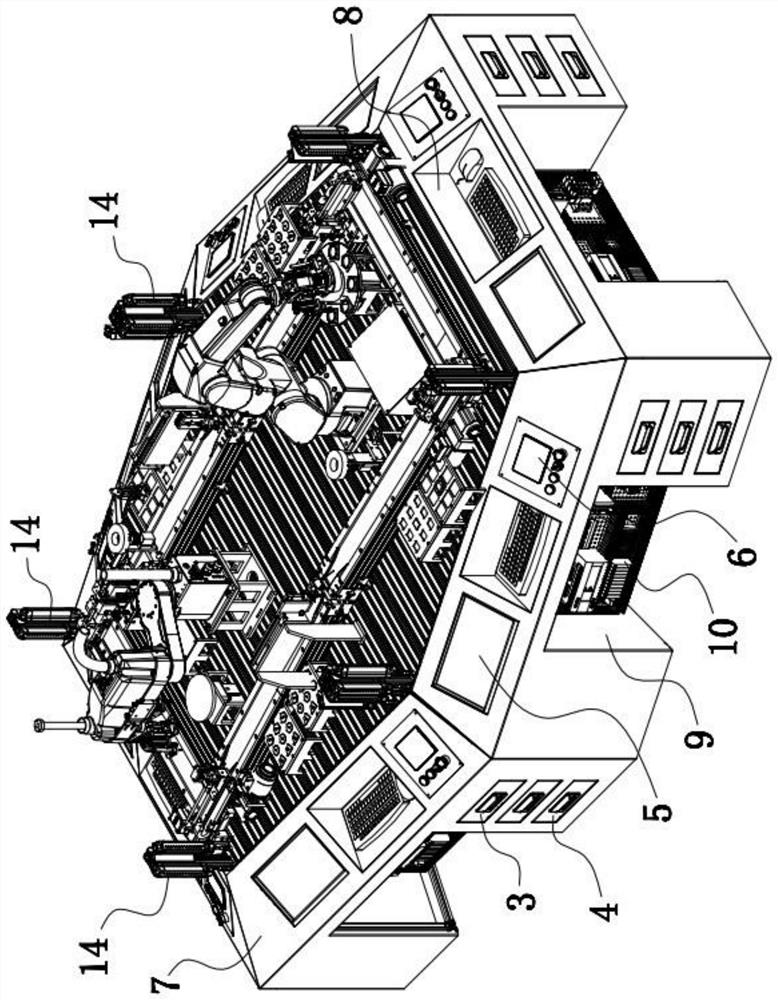

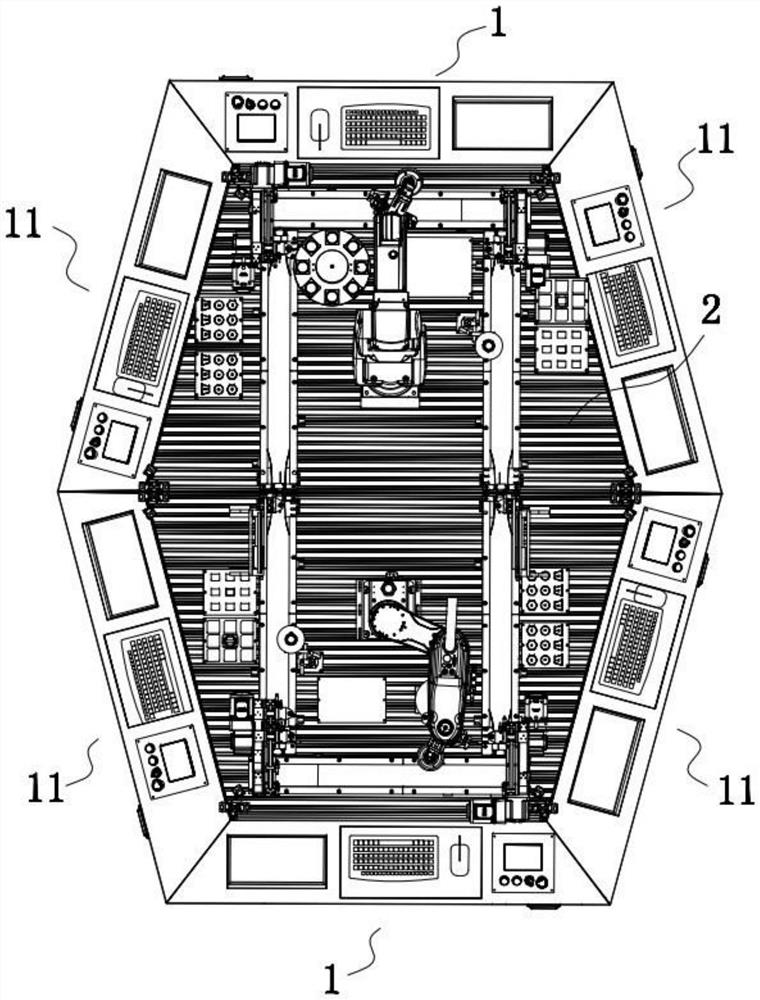

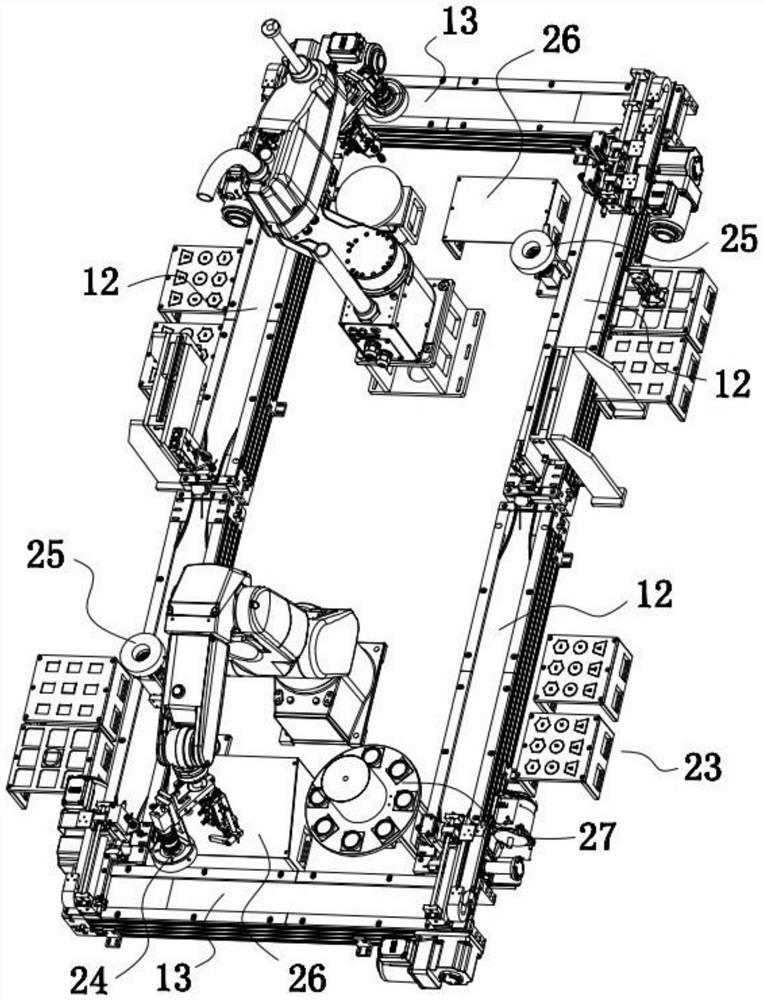

[0037]In order to achieve the purpose of the present invention, a robot training practice platform for splicing industrial scene application includes: a table body unit, the outline of which is an isosceles trapezoid in top view, and the edge of the table body unit includes three control tables, and adjacent control tables are respectively The length direction forms an obtuse angle; the two table body units are detachably spliced, and the outline of the top view of the two table body units after splicing is hexagonal; the scene simulation mechanism, the top of the table body unit is provided with a workbench, and the workbench is provided with Scenario simulation mechanism; each table body unit is provided with two parallel side linear conveyor belts 13, the same ends of the two side linear conveyor belts 13 are vertically connected with the end linear co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com