Cast-in-situ pedestal pile with variable bearing and its construction method

A grouting pile and variable technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of low bearing capacity of cast-in-place piles, large settlement of buildings, large amount of discharged mud, etc., and achieve good pile quality. , save materials, improve the effect of pile-soil interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

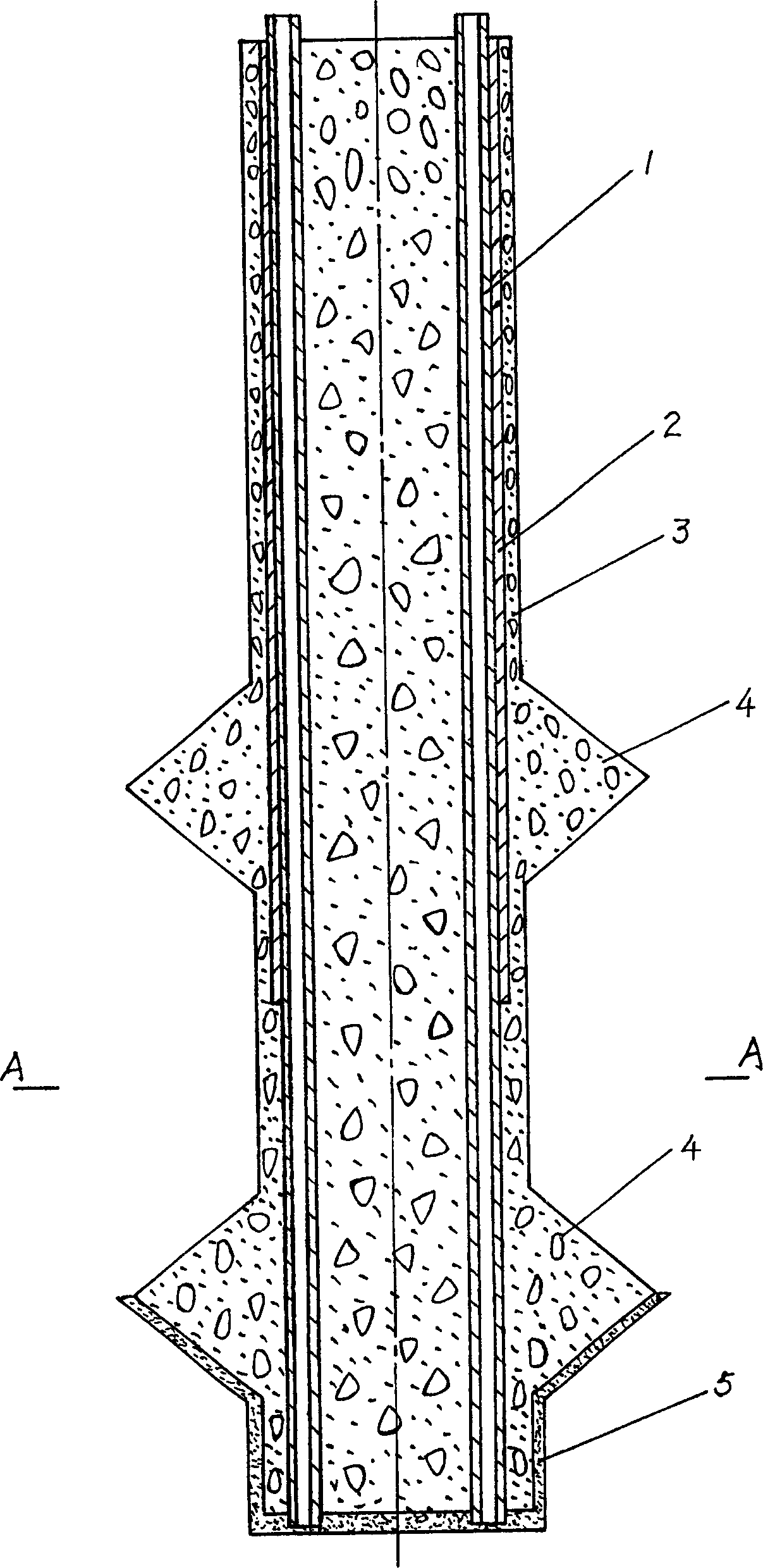

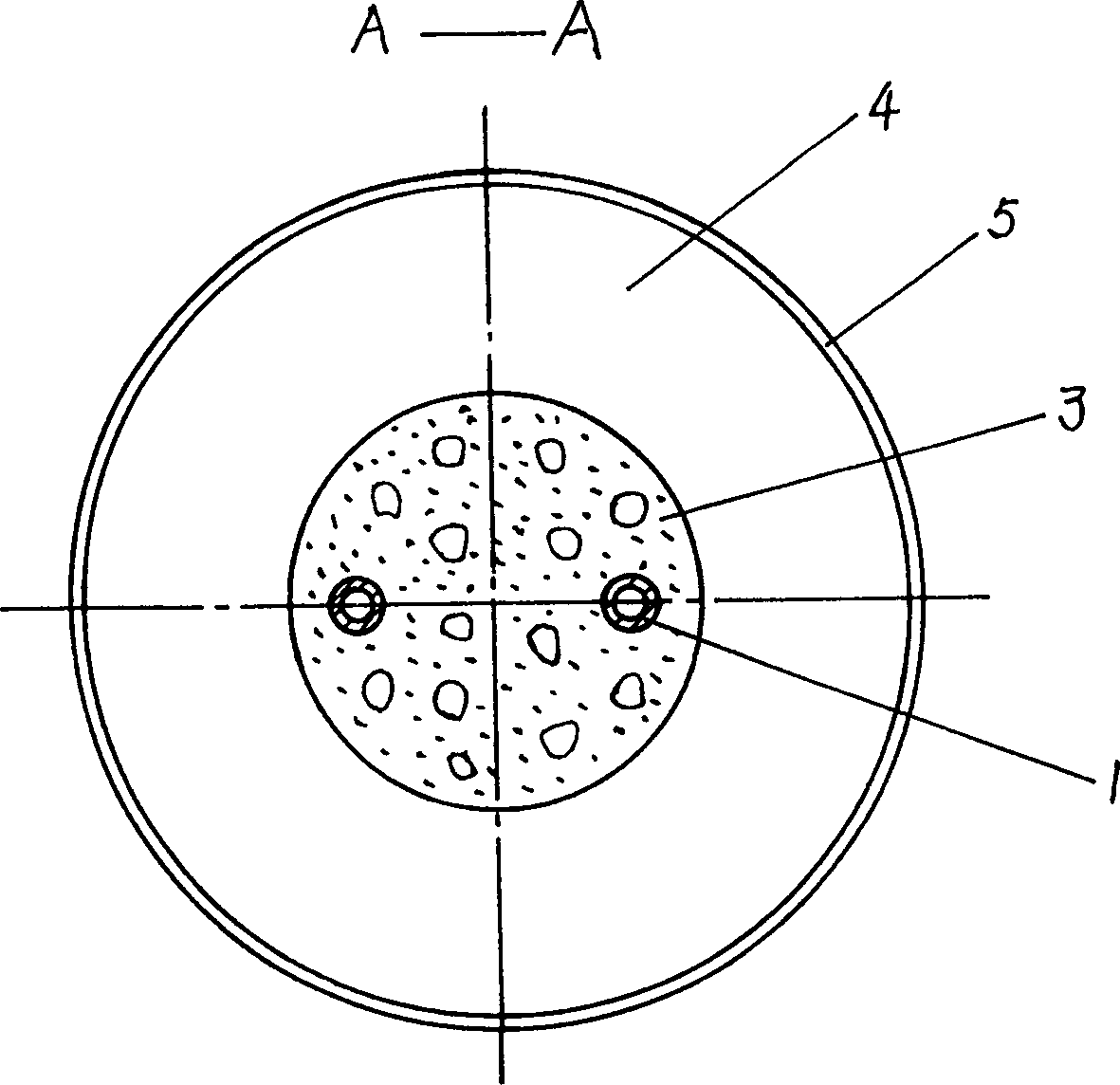

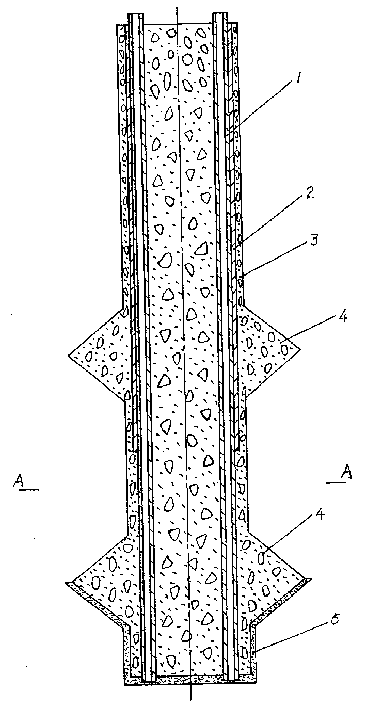

[0016] Such as figure 1 and figure 2 As shown, the variable bottom expansion support disc grouting pile in this embodiment includes a steel cage 2, concrete piles 3, grouting pipe 1 and variable support discs 4 of two circular conical bodies, Wherein: it also includes cement slurry 5; Grouting pipe 1 is tied on the reinforcement cage 2, and reinforcement cage 2 is arranged in the concrete pile 3, makes the grout inlet of grouting pipe 1 stretch out the top surface of concrete pile 3, The grout outlet of the grouting pipe 1 protrudes from the bottom of the concrete pile 3, so that the cement slurry is injected into the bottom of the pile; two variable support plates 4 are respectively arranged at the bottom of the concrete pile 3 and the middle of the pile , The cement slurry 5 is arranged at the bottom of the concrete pile 3 and the bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com