Variable resistor

A resistor and variable technology, used in adjustable resistors, resistors, resistor components, etc., can solve problems such as improper bonding and poor sealing, to prevent incorrect bonding or removal, and ensure performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

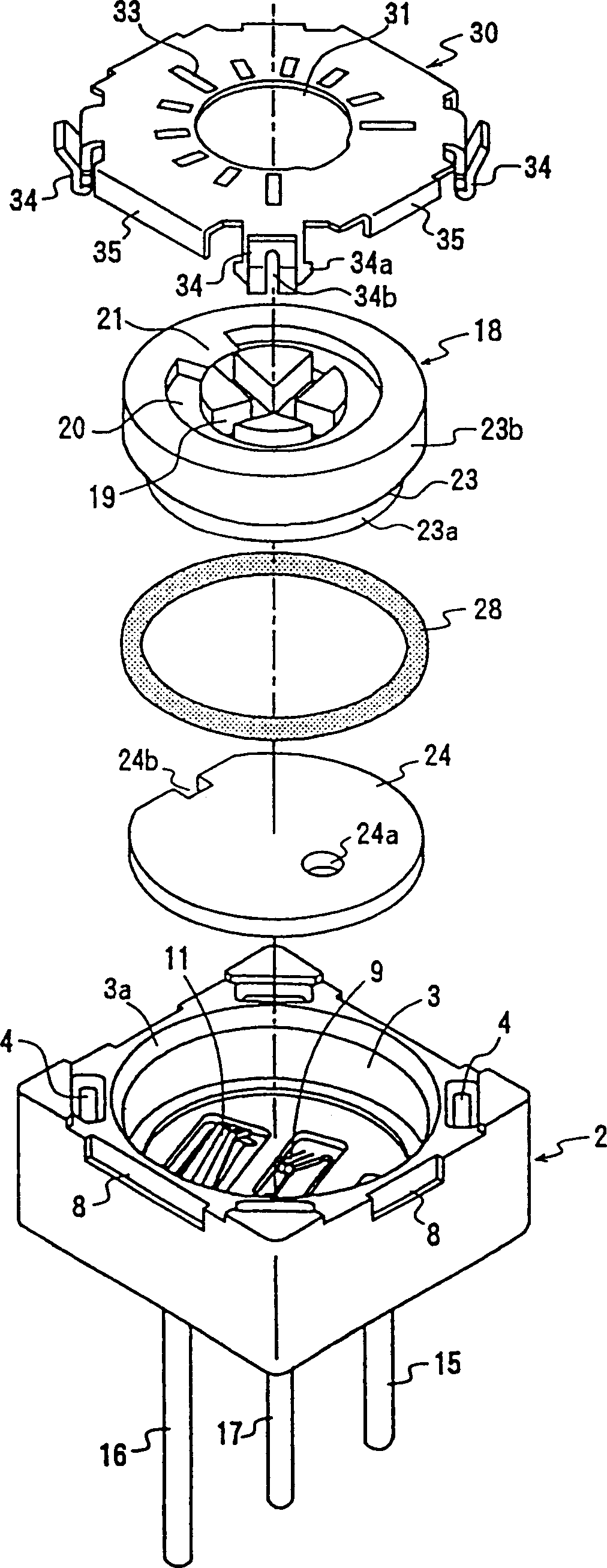

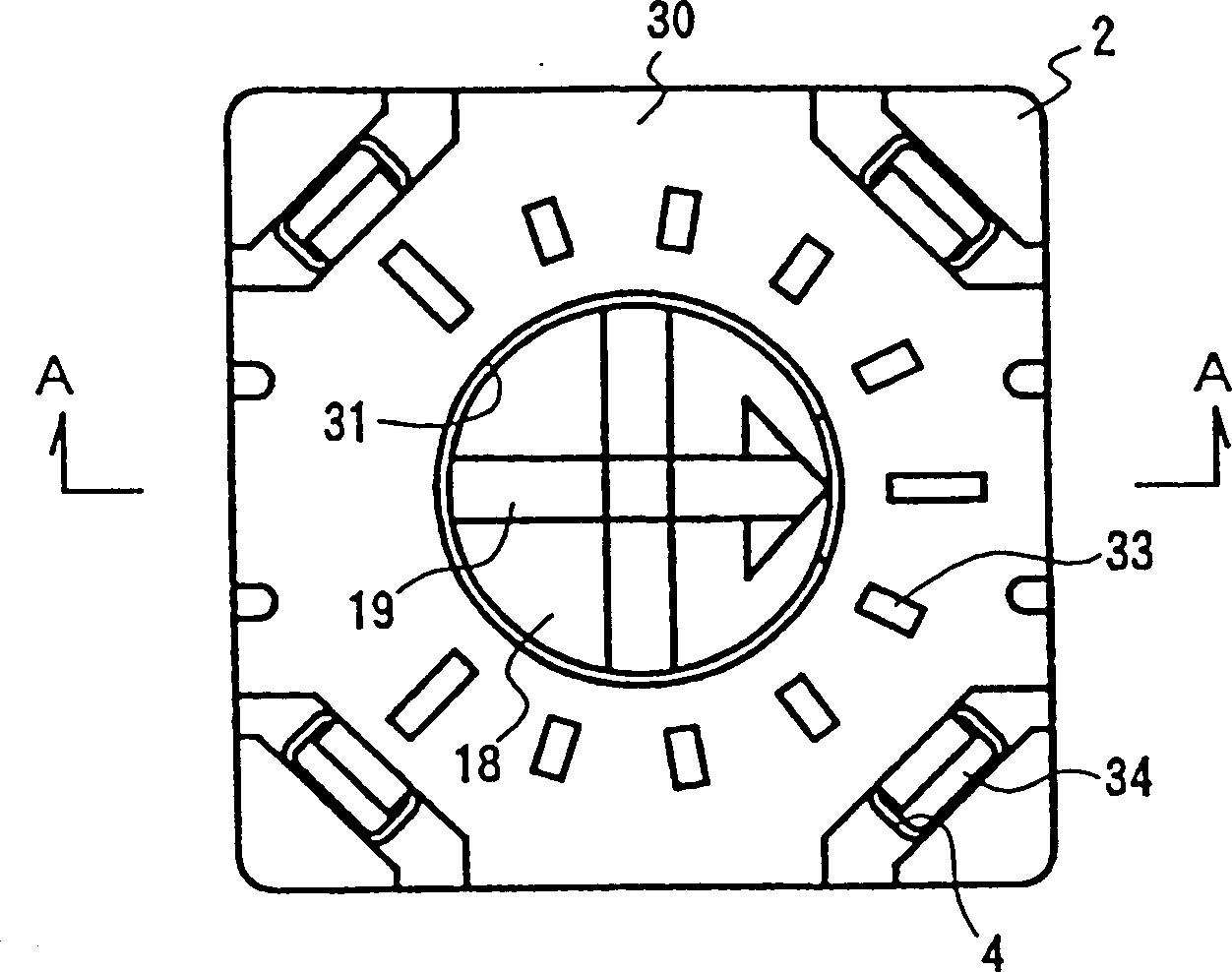

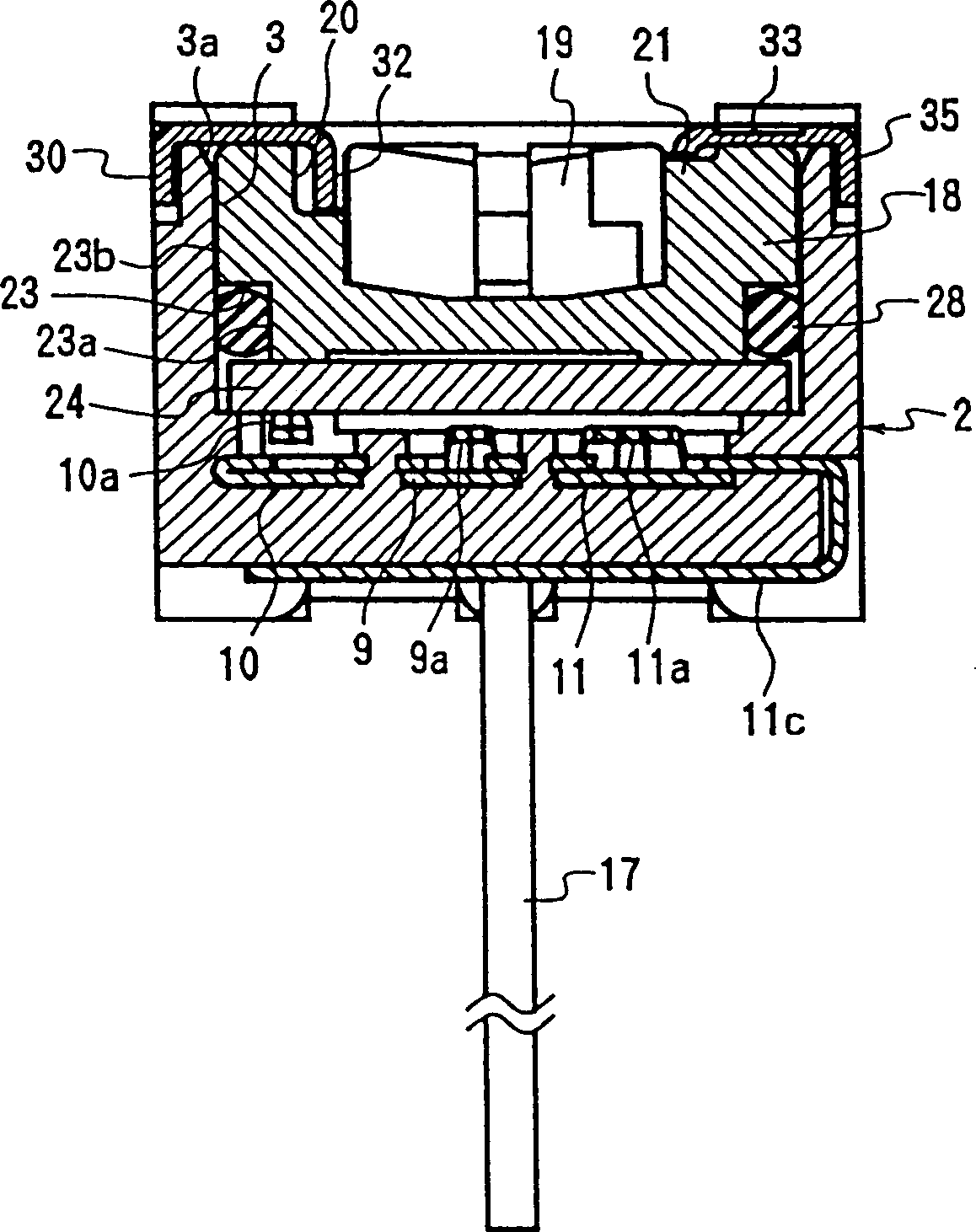

[0036] Figure 1 to Figure 8 A variable resistor according to a first embodiment of the present invention is shown. The variable resistor 1 includes a case 2 ; sliders 9 , 10 and 11 ; lead terminals 15 , 16 and 17 ; a rotor 18 ; a resistor substrate 24 ;

[0037] Through polyamide-type thermoplastic resins such as 46 nylon with high heat resistance, polybenzene sulfide, polybutylene terephthalate, liquid crystal polymer, or thermal insulation such as epoxy resin, hexadiene titanate, etc. The cured resin forms the housing 2 which is stable in high temperature environments and resistant to heat during welding. A bottom recess 3 having a circular cross section as an example of an accommodation space is formed in the housing 2 and is designed so that the rotor 18 accommodated in the recess 3 can freely rotate. A tapered guide surface 3 a for guiding the O-ring 28 is formed at the upper edge of the recess 3 of the housing 2 . Engagement holes 4 for engagement with engaging claws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com