Device and method for evening out thickness of metal layers on electrical contact points on items that are to be treated

A technology of metal plating and contact parts, applied in the direction of contact devices, sealing devices, printed circuit secondary treatment, etc., can solve the problems of inevitable electroplating and transmission component corrosion, impossible board, wrinkling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

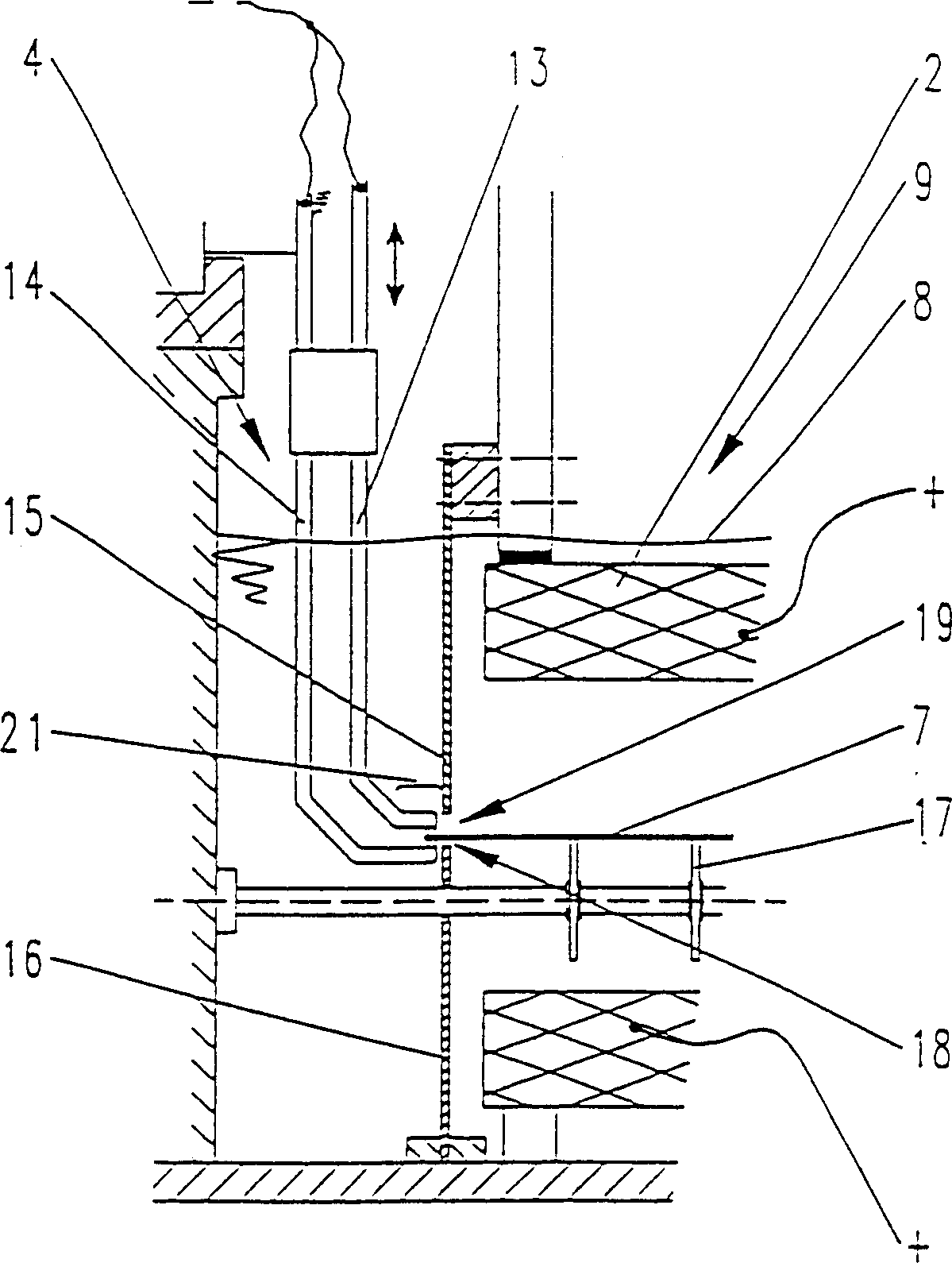

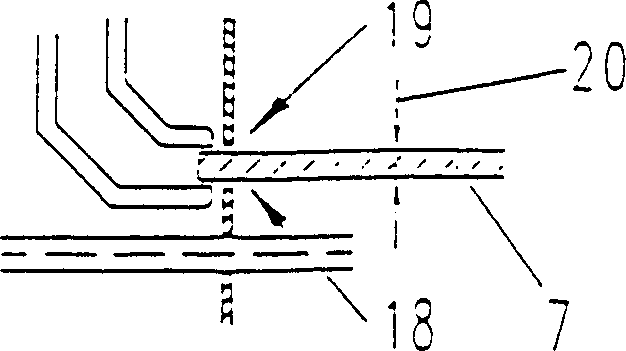

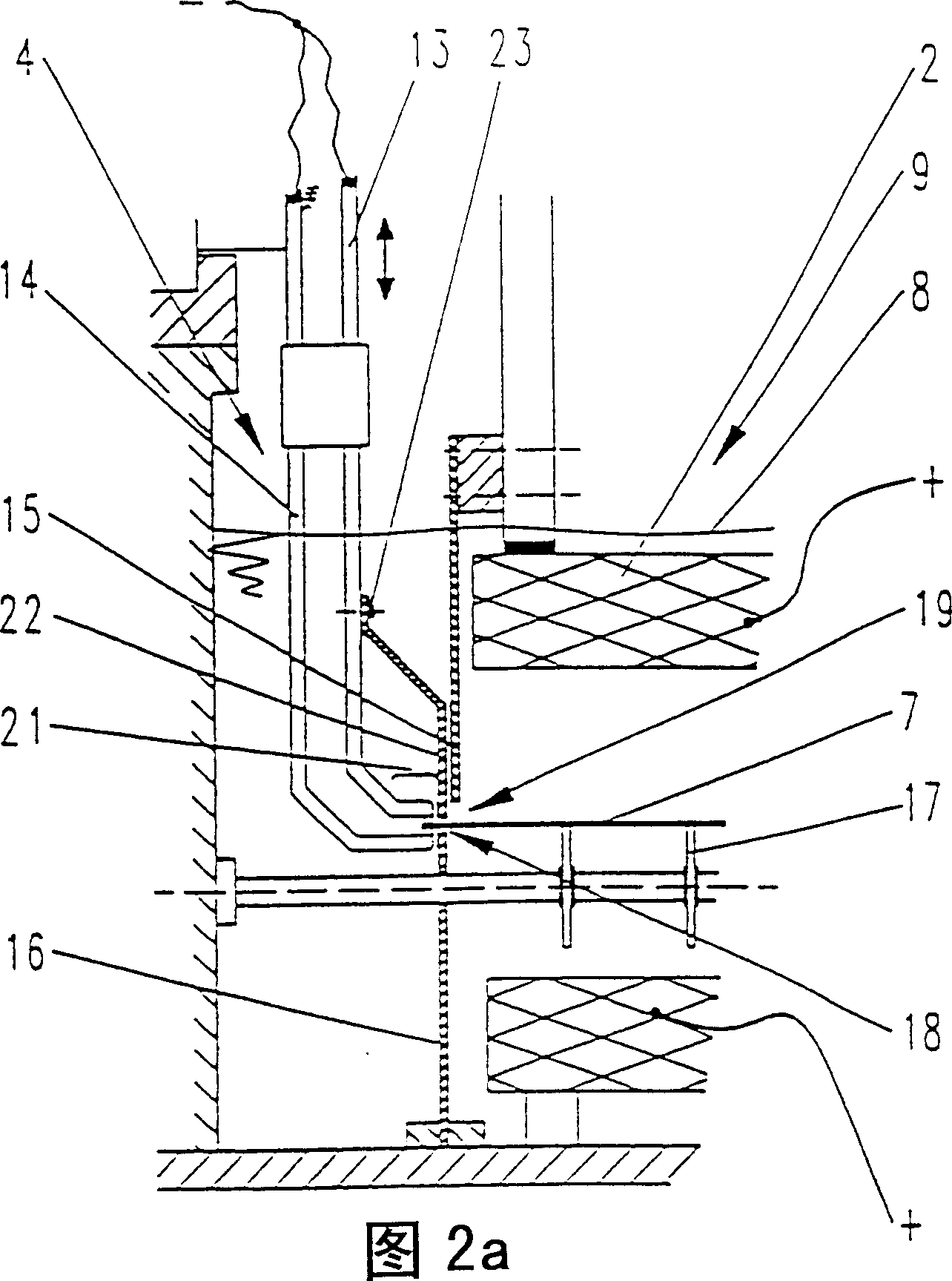

[0040] exist Figure 5 A set of common electroplating equipment is represented in . Inside the working container 1 there is an upper basket anode 2 and a lower basket anode 3 . A continuous electroplating plant that is practically six meters long consists, for example, of 25 upper basket anodes and 25 lower basket anodes. They are arranged one after the other along the conveying direction of the items to be processed, for example printed circuit boards. Therefore, in the view of FIG. 1 , only one upper basket anode and one lower basket anode can be seen in the conveying direction. Also in the figure the clips 4 are also arranged one after the other. The distance from one clip to the other is, for example, 60 mm. The gripper 4 is fixed on a motor-driven endlessly circulating conveyor belt 5 . The clip 4 holds the item 7 to be treated at the clip contact point 6 (Z partial view). The gripper drives and conveys the item to be processed through the electroplating equipment. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com