Arc welding wire

A technology of arc welding and welding wire, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve problems such as difficulty in obtaining surface information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

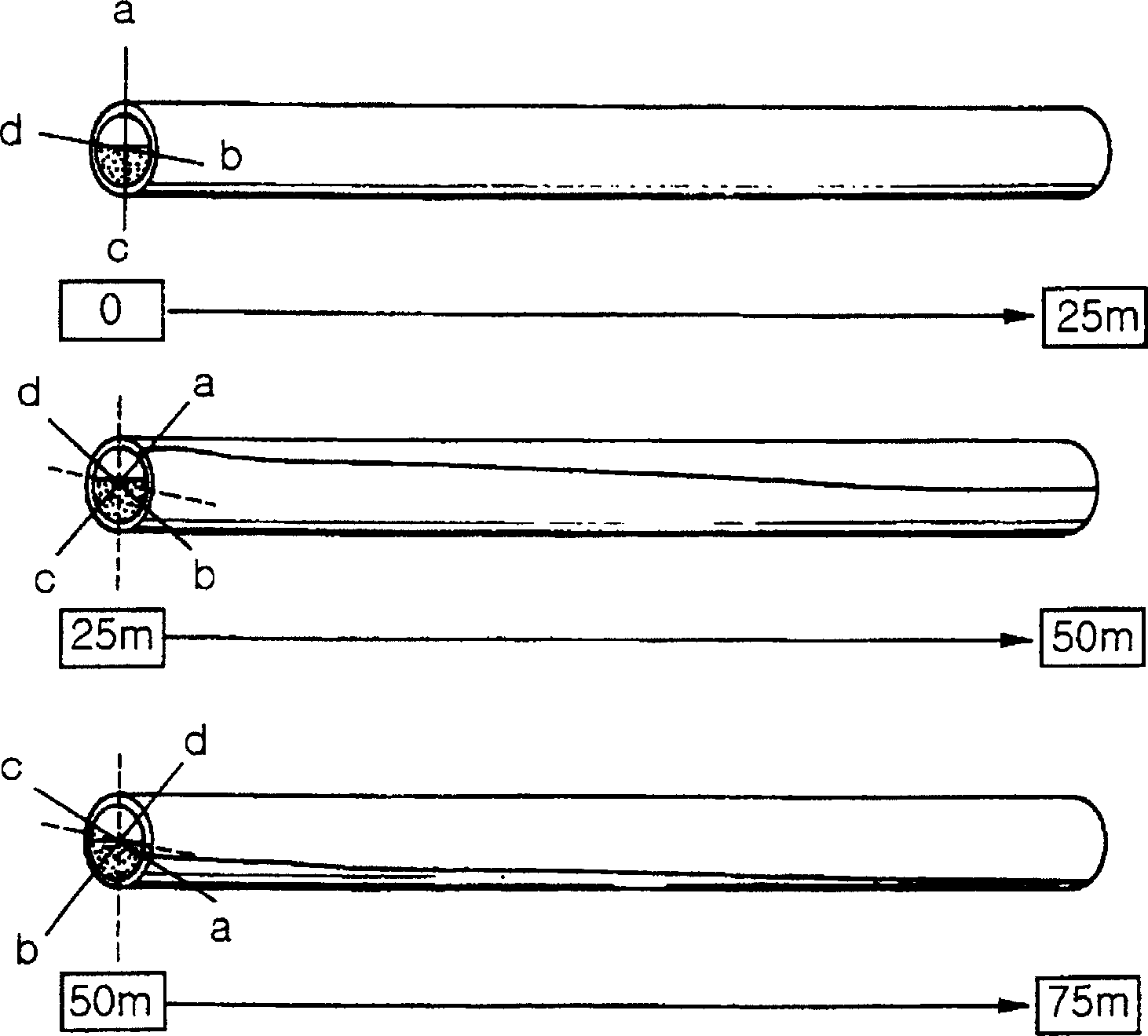

[0077] Next, an example of the method for producing the arc welding wire of the present invention will be described.

[0078] First, the manufacture of the solid welding wire will be described. The wire rod (welding wire) with a diameter of 5.5 mm to 8.0 mm is made by hot rolling or drawing method, and the wire rod is pickled by chemical or physical chemical methods to completely remove the rust on the surface, and then washed repeatedly with warm water . At this time, care should be taken not to cause acid corrosion due to long-term pickling, and special attention should be paid to hydrogen embrittlement caused by hydrogen generation. In addition, due to the generation and adhesion of polluting substances such as powder (the powder is excessively pickled and adhered to the surface), it will make it difficult to transport and blow in the lubricant during wire drawing, which is a factor that hinders wire drawing. Proper pickling.

[0079] In order to improve the conveyance a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap