Solar battery module arranging method and solar battery module array

A technology of solar cells and configuration methods, applied in the field of configuration of solar cell modules and arrays of solar cell modules, capable of solving problems such as difficult electrical connections, low execution efficiency, and large distances, and achieving the effects of easy electrical connections and increased area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

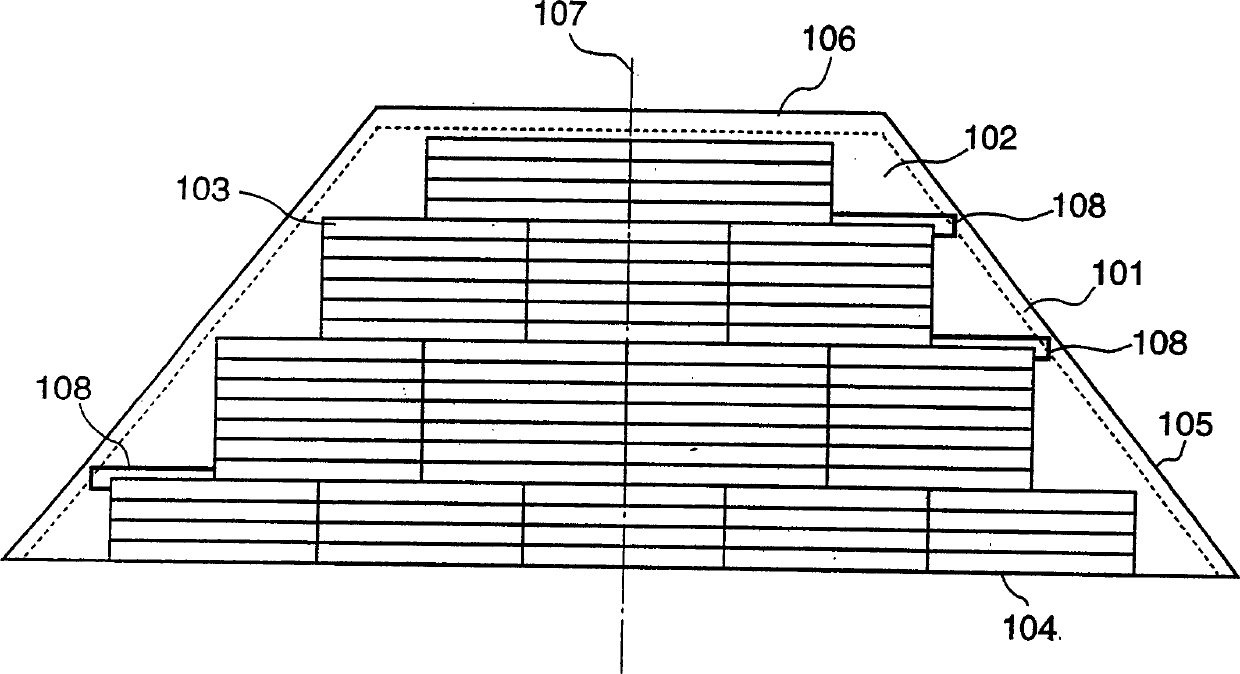

[0104] Fig. 1 is a graph showing that a covering material integrated solar cell module SR-02 (covering width W = 200mm, length λ = 2,000mm) available from Canon for a stepped roof is set on a trapezoidal roof. Sets the view of the state within scope 102. The length L1 of the eaves 104 of this roof is 12,000 mm, the length L2 of the ridge 106 is 5,000 mm, and the slope length A1 of the roof is 4,500 mm. Follow the steps shown in the flowchart of FIG. The interval g1 of the range 102 is 0 mm, the interval g2 from the roof ridge 106 to the allowable installation range 102 is 200 mm, and the interval g3 from the roof boundary 105 to the allowable installation range 102 is 200 mm. The setup steps are briefly described below. In the flow chart of FIG. 20, the same numerals as those in FIG. 19 denote the same steps, and their detailed descriptions will be omitted.

[0105] [Calculation of maximum number of set rows (steps S1 to S3)]

[0106] In the present embodiment, the covering...

no. 2 example

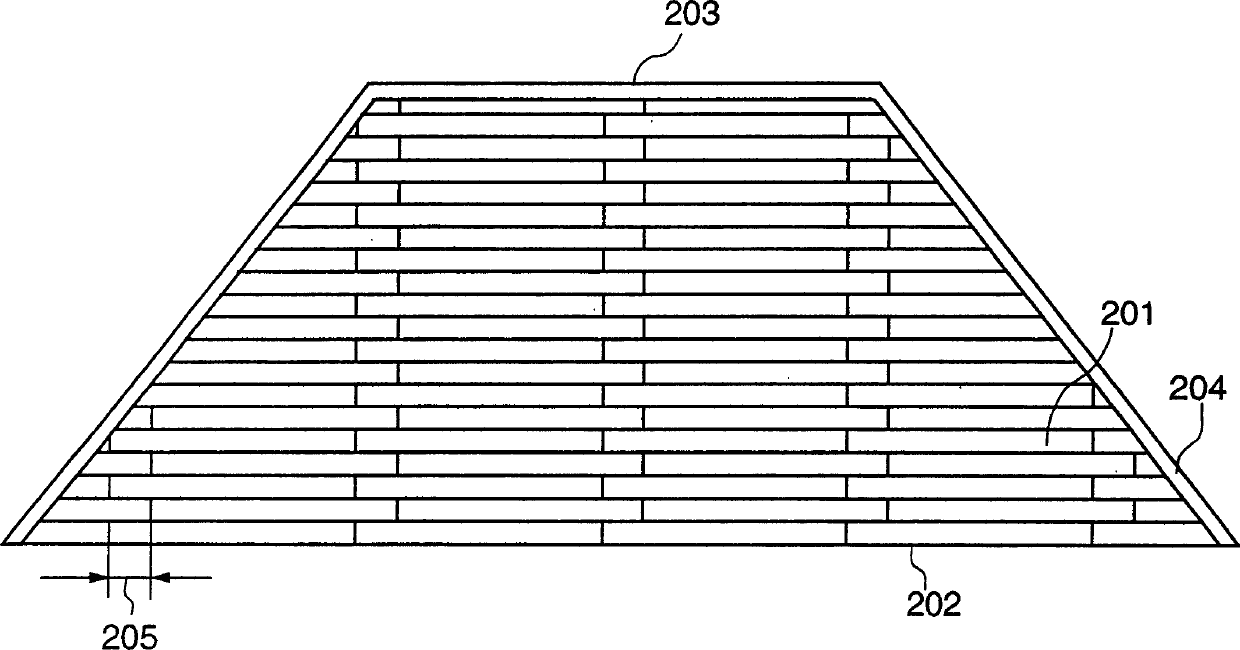

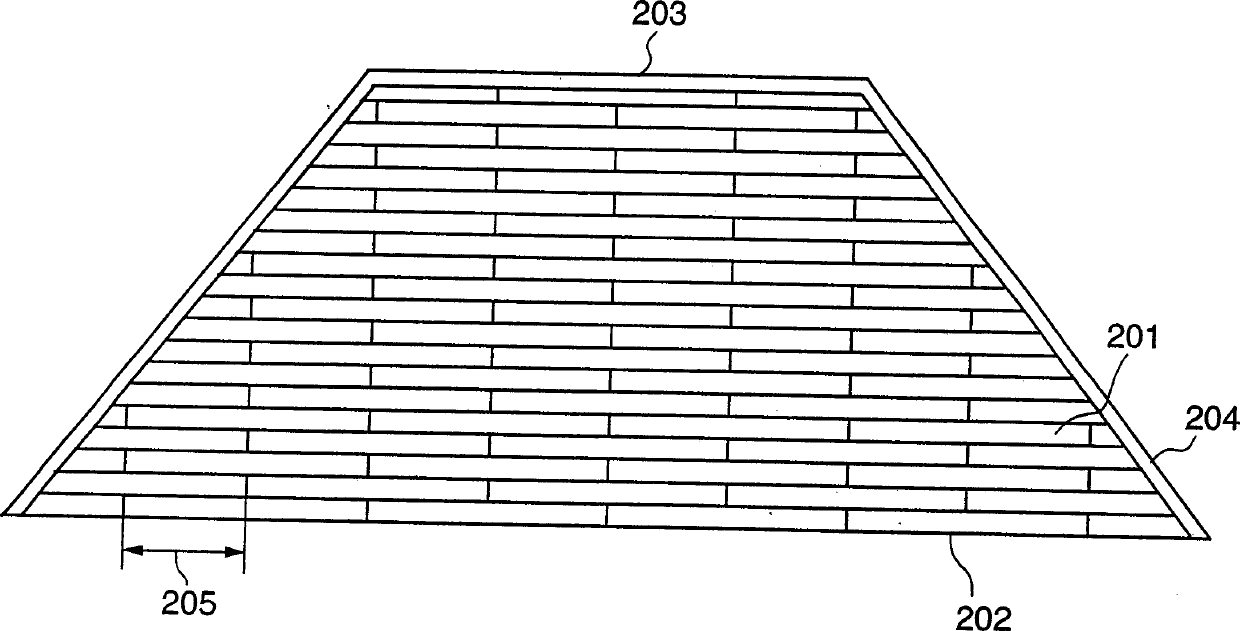

[0122] FIG. 7 is a view showing a state in which the above-described covering material-integrated solar cell module SR-02 is installed in the allowable installation range 102 of the roof installation surface 101 similarly to FIG. 1 . Following the steps shown in the flowchart of FIG. 21 , let the offset width 609 be 200mm. The setup steps are briefly described below. In the flowchart of FIG. 21, the same numerals as those in FIG. 19 denote the same steps, and their detailed descriptions will be omitted. Calculate the maximum setting number Cmax (steps S1 to S3), calculate the maximum setting number Nmax (step S4) of each row and the setting (step S5) at the central part of the setting surface is the same as the operation in the first embodiment, its Detailed description will be omitted.

[0123] [Offset (step S7)]

[0124] Since the offset width 609 is 200 mm, the module group is alternately offset to the left or right by 100 mm in row units.

[0125] [judgment (step S8)] ...

no. 3 example

[0135] FIG. 12 is a view showing a state where the above-described covering material-integrated solar cell module SR-02 is installed in an allowable installation range 1202 of a triangular roof. The length L1 of the eaves 1204 of this roof is 9,200 mm, and the slope length A1 of the roof is 5,050 mm. Follow the steps shown in the flow chart of FIG. The distance g3 from the roof boundary 1205 to the allowable installation range 1202 is 200 mm. The setup steps are briefly described below. In the flowchart of FIG. 22, the same numerals as those in FIG. 19 denote the same steps, and their detailed descriptions will be omitted.

[0136] [Calculation of maximum number of set rows (steps S1 to S3)]

[0137] The length A of the allowable setting range 1202 in the oblique direction is given by:

[0138] A=A1-g1=5,050-200=4,850mm

[0139] The number of rows C is given by the following inequality, and the maximum set number of rows Cmax is 24:

[0140] C≤4,850 / 200=24.25

[0141] [c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com