Integrated mini non-valve pump type capillary electrophoresis chip

A capillary electrophoresis and valveless technology, which is applied in the direction of material analysis, measuring devices, instruments, etc. through electromagnetic means, can solve the problems of continuous detection speed and detection accuracy, long time consumption, and affecting detection accuracy, etc., to shorten the continuous The effect of shortening the detection time, reducing the detection cost and simplifying the detection equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

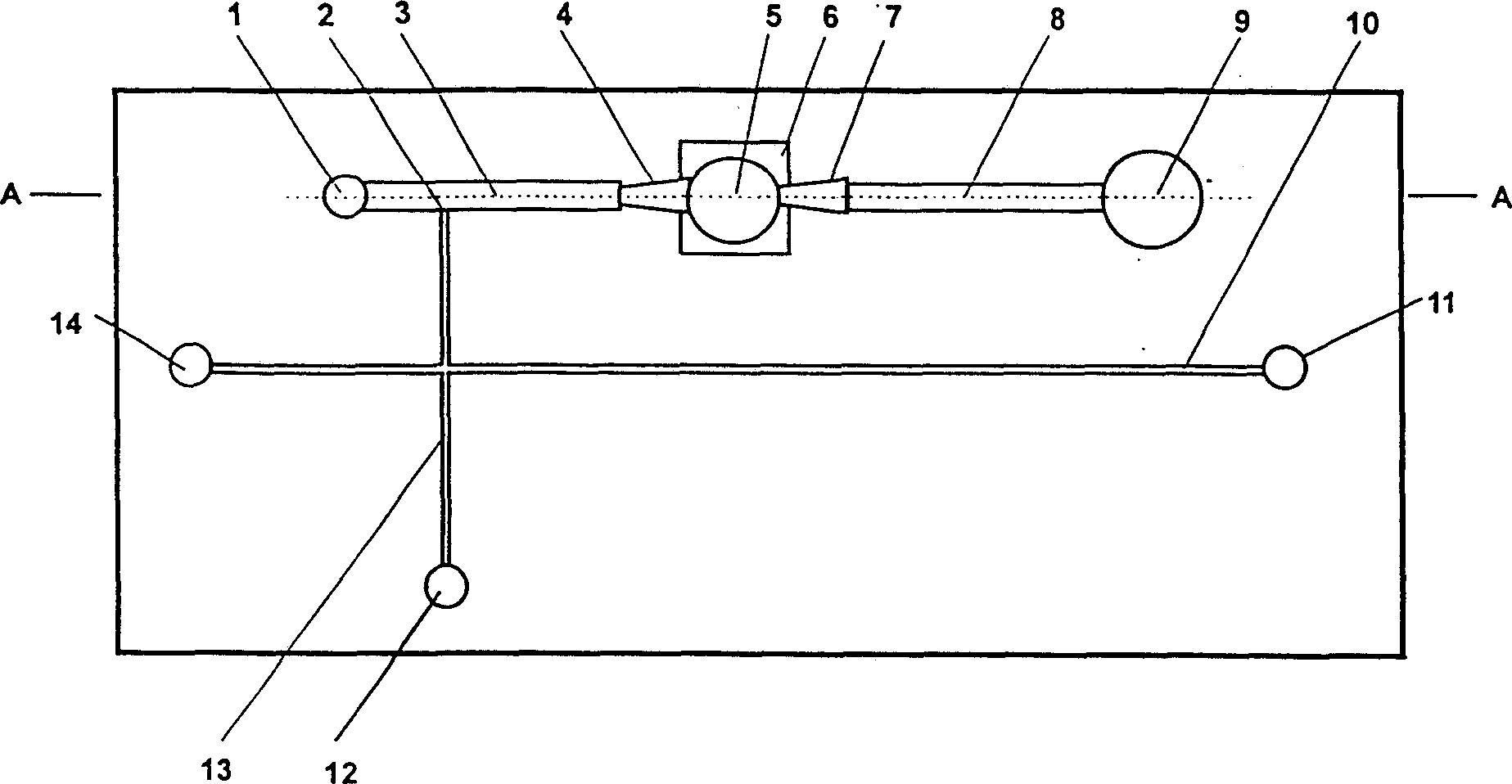

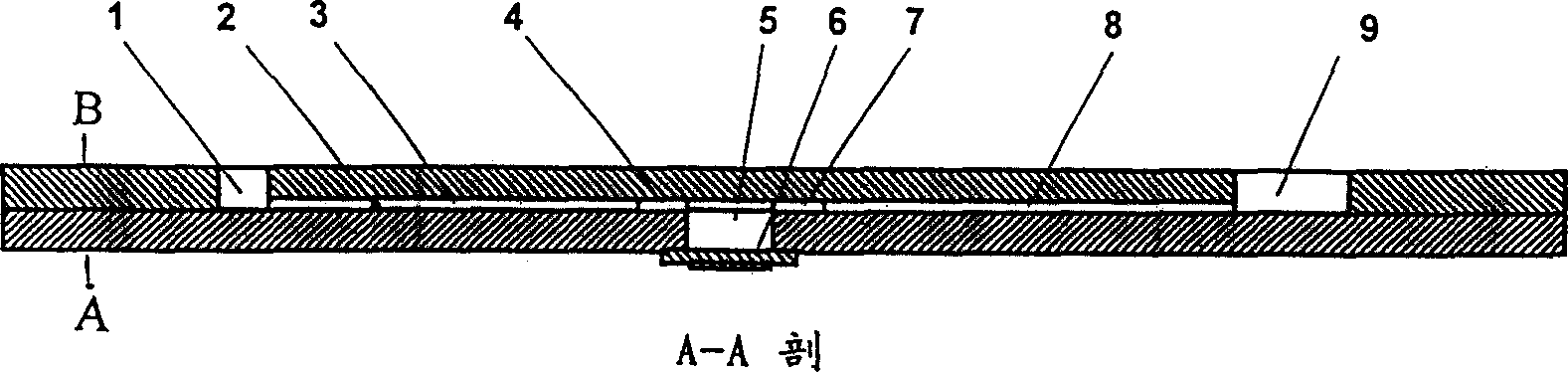

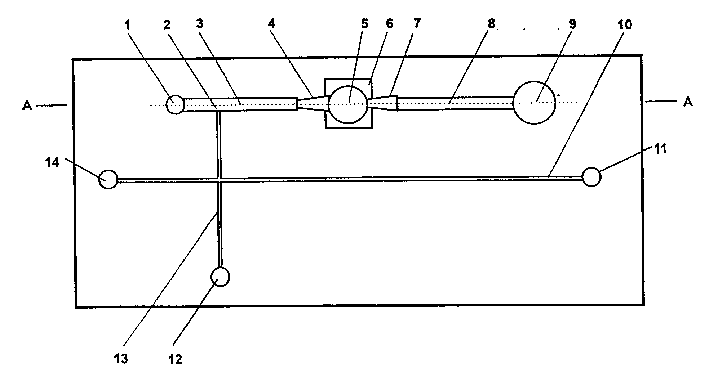

[0016] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0017] like figure 1 , figure 2 As shown, the present invention includes: the first base material A and the second base material B are bonded together, the first base material A is equipped with a miniature valveless pump composed of a cavity 5 and a driving film 6, On the joint surface of the second base material B, the inlet flow channel 3 and the outlet flow channel 8 respectively located on both sides of the cavity body 5 are etched. One end of the inlet flow channel 3 is connected to the sampling tank 1, and the other end is gradually enlarged The trapezoidal inlet channel 4 is connected to the inlet end of the valveless pump, one end of the outlet channel 8 is connected to the waste liquid tank 9, and the other end is connected to the outlet end of the valveless pump through the gradually reduced trapezoidal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com