Refrigeration device

A refrigeration device and condenser technology, which is used in household refrigeration devices, refrigerators, refrigeration components, etc., can solve the problems of reducing the surface temperature of the compressor, limiting the heat output of the compressor, and overflowing the melted water, shortening the distance and improving the evaporation. Efficiency, optimal heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

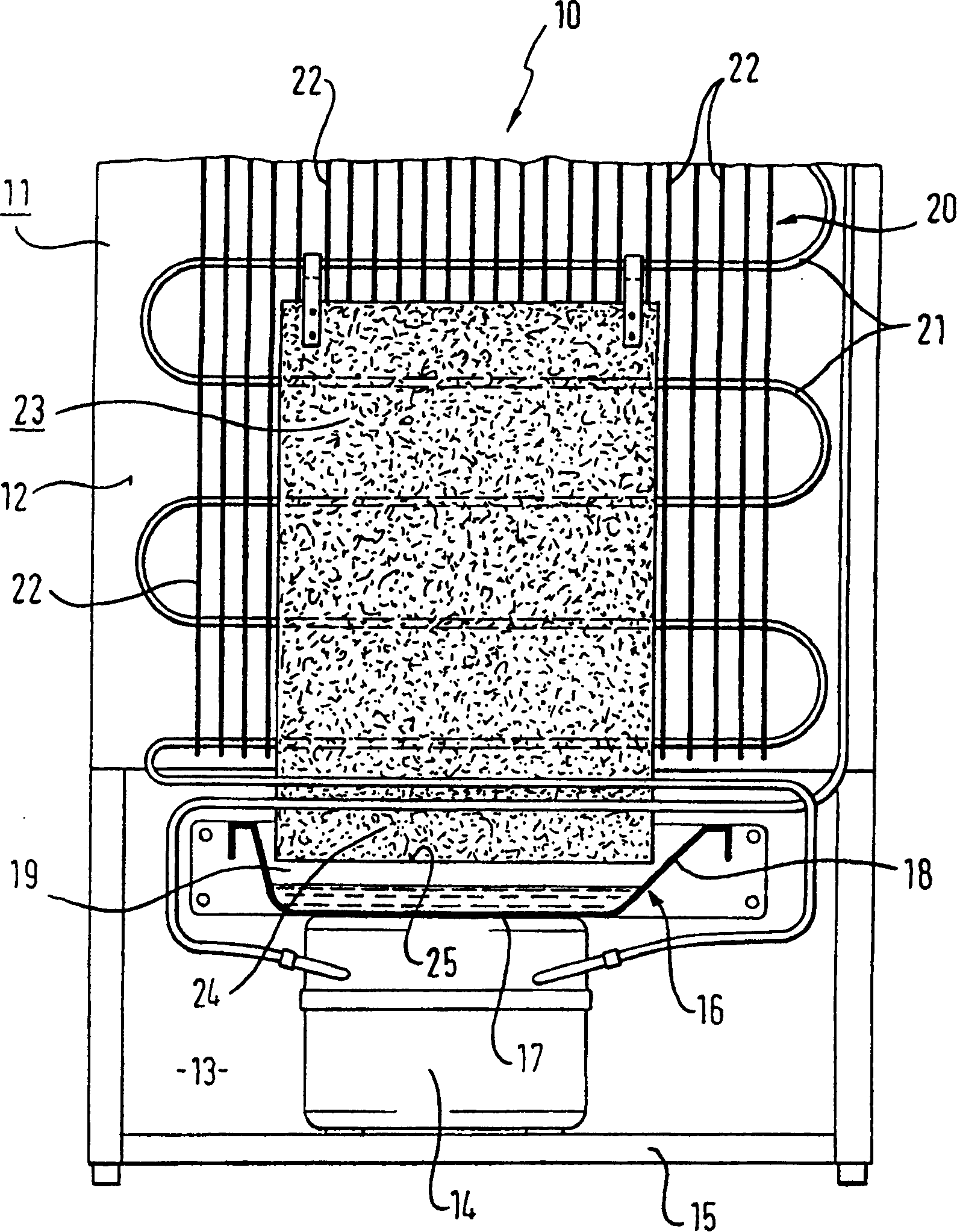

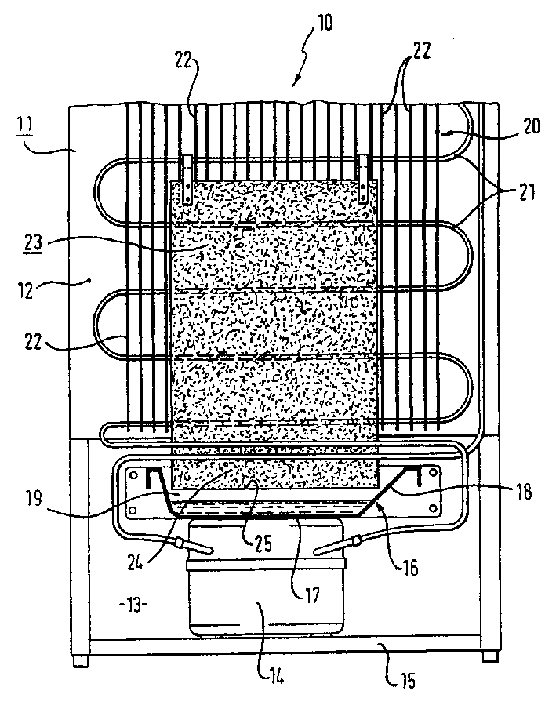

[0020] According to the single figure, which is a simplified cutaway view, it shows a refrigeration unit designed as a table refrigerator 10 with a thermally insulated housing 11 . On its back side 12, the shell has a recessed machine cavity 13 relative to the back side 12 at its lower end. In this machine cavity 13, a refrigeration compressor 14 is fixed on the width of the machine cavity 13. on the support rail 15. At its upper end opposite the support rail 15, the refrigeration compressor 14 supports a condensate collecting pan 16, for example integrally molded from injection-molded plastic, into which the melted water produced during the defrosting of the table-top refrigerator 10 is directed. The plate is 16 miles. The condensate collecting pan 16 has a base 17 and a side wall 18 arranged around the edge of the base, which together with the base 17 forms a condensate collecting chamber 19 .

[0021] A flat condenser 20 is arranged on the rear side 12 at a distance above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com