Delay valve without piston

A time-delay valve and no-piston technology, applied to valve details, diaphragm valves, valve devices, etc., can solve the problems of inconvenient maintenance, complex structure, high cost, etc., and achieve the effect of avoiding waste, wide range of production materials, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

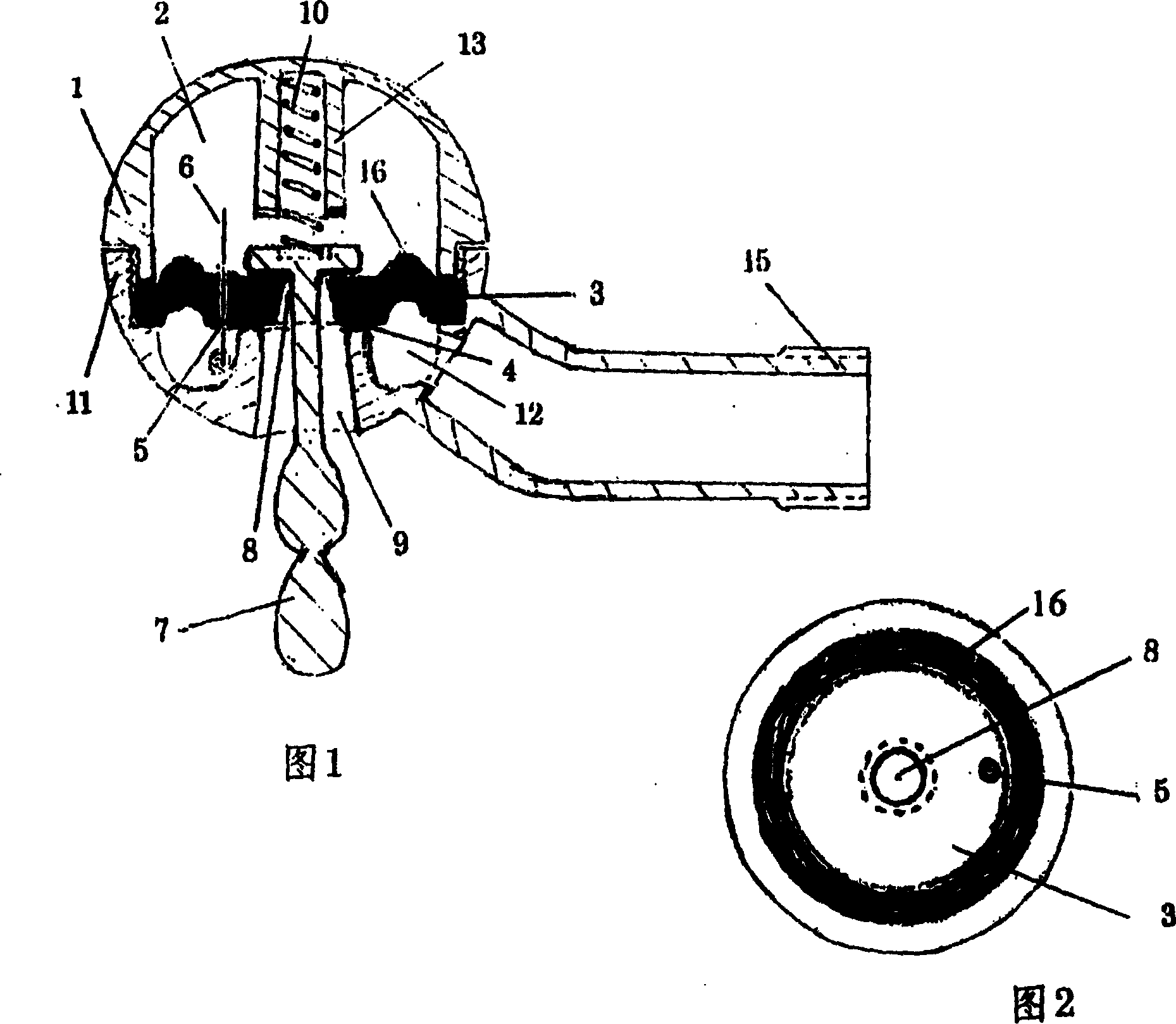

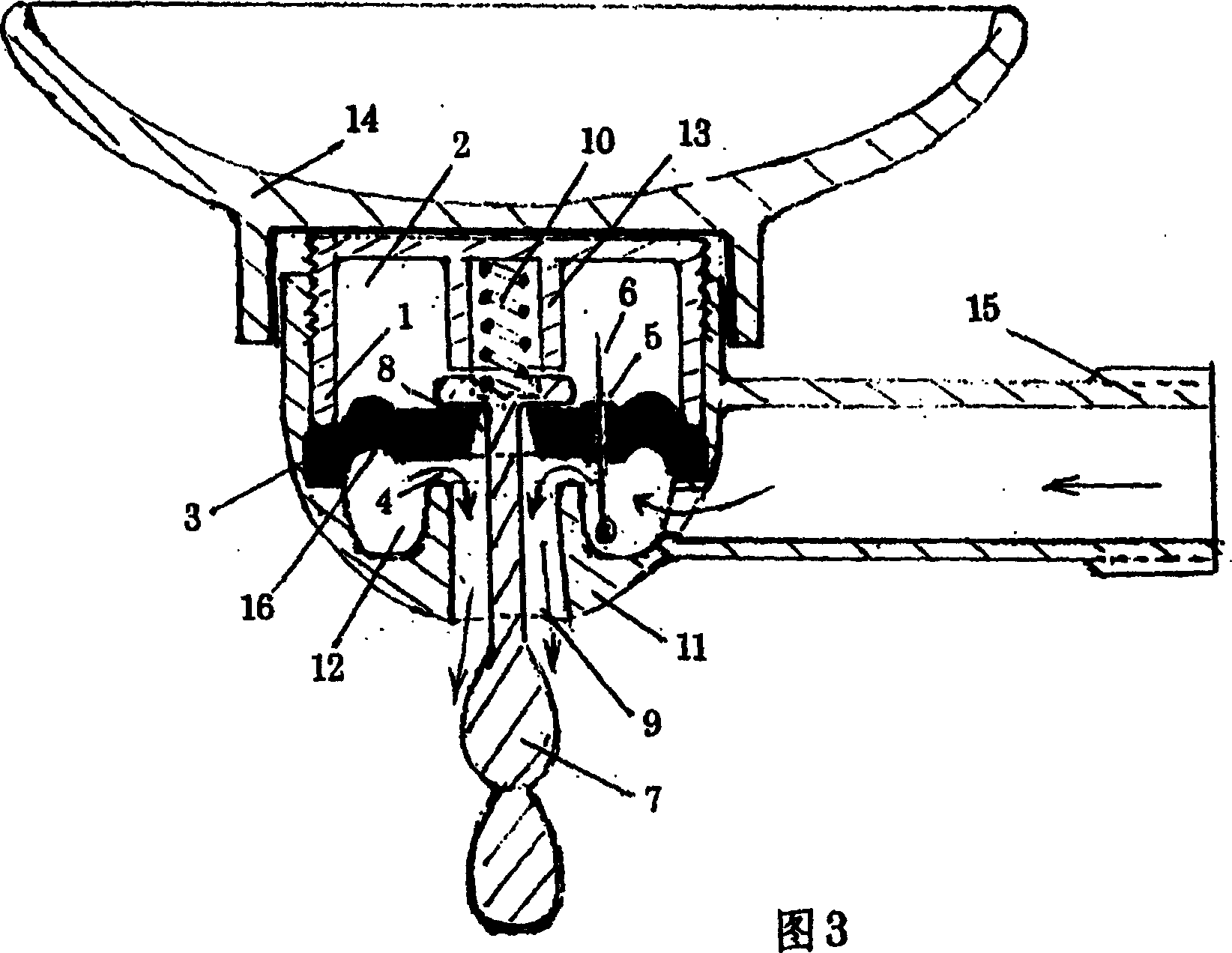

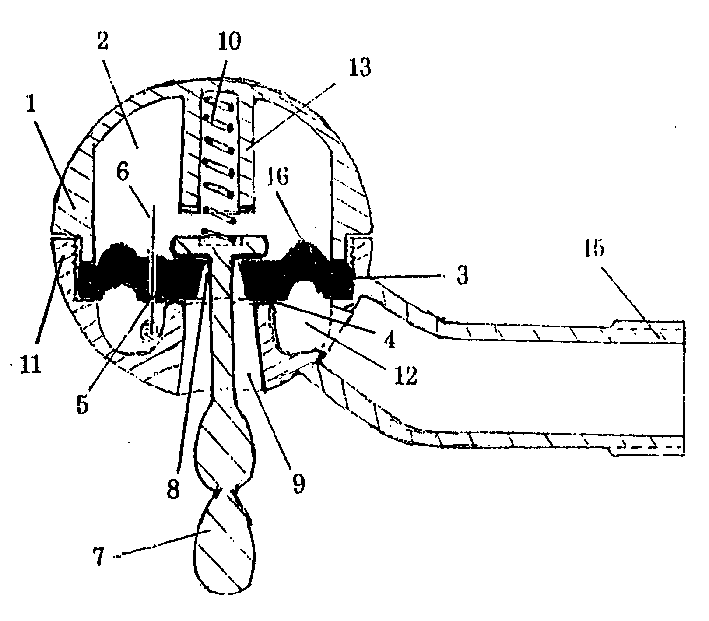

[0016] See Figure 1. The inner space of the special-shaped valve cover 1 is the water-air chamber 2. When the water-air chamber is normally closed, the lower part of the water-air chamber is filled with a certain amount of tap water, and the upper part is compressed air, whose pressure is equal to that of the water supply. The damping hole nozzle 5 is riveted on the eccentric side of the cup to communicate with the water supply. The small damping hole is easily attached by rust and affects normal use. Therefore, a trembling needle 6 is interspersed in the damping hole. The needle moves slightly under the action of water flow. It can prevent the adhesion of rust and the clogging of impurities. Changing the trembling needles with different diameters can adjust the delayed self-closing time. When water is needed, touch the downward-hanging "dripping" "T"-shaped pressure relief lever 7 to release the pressure of the water in the water-air chamber of the special-shaped valve cover,...

Embodiment 2

[0018] As shown in Figure 1, the structure of this embodiment is basically the same as that of the previous embodiment, the difference is that the air cushion uses other flexible or fluid materials to fill the water and air chamber instead of air, and the same principle can achieve the effect of delayed self-closing. It is still possible to process the no-piston time-delay handwashing valve into the shape shown in Figure 3, and the top of the special-shaped valve cover is clamped to a similar dish-shaped movable small plate 14, which is for placing, washing products, trinkets, etc., beautiful and practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com