Preparation method of positive plate lead paste of lead-acid battery

A lead-acid battery and a production method technology, applied in lead-acid battery electrodes, battery electrodes, circuits, etc., can solve the problems of early battery capacity attenuation, poor binding force of active substances, and battery life termination, etc., and achieve extended cycle life and utilization. The effect of high rate and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

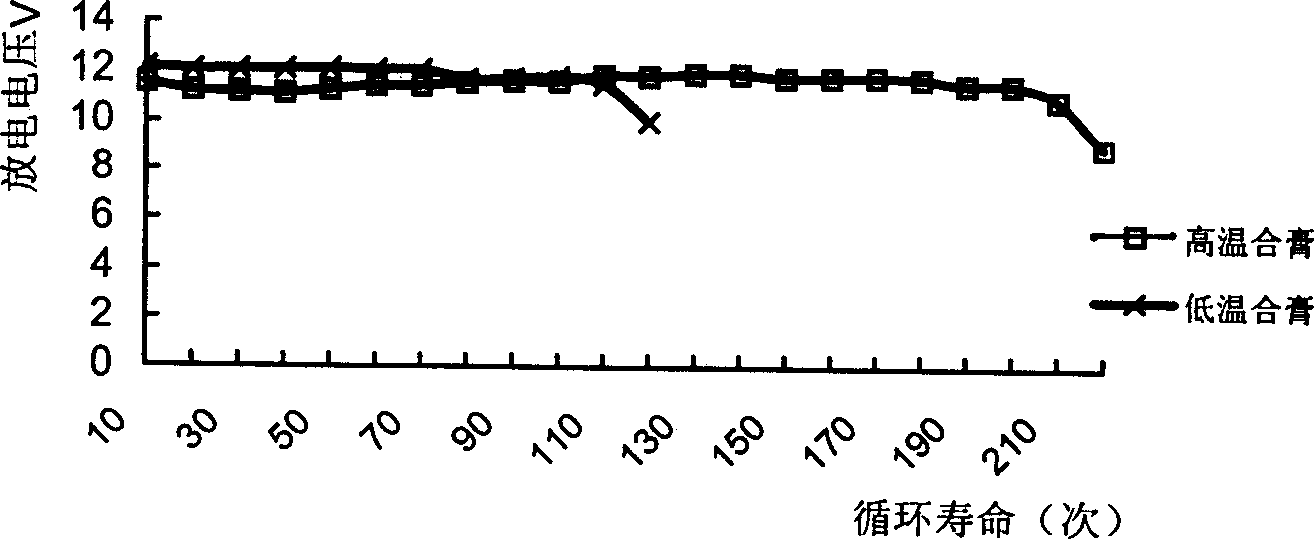

Embodiment 1

[0007] Embodiment 1: Put 50kg of lead powder (containing PbO73%~84%) into the paste mixing machine with heat exchanger, put 0.02kg of fiber at the same time, start the mixer, add 6kg of lead powder while stirring the lead powder. Purified water, stirred for 20 minutes, and then added in a spray form with a concentration of 1.40g / cm 3 Add 4.5kg of sulfuric acid, stir while adding, stir for 5 minutes after adding the acid, and reach 70°C under the temperature control of the heat exchanger of the paste mixing machine. Apparent density can reach 4.1~4.2g / cm 3 , at this time, lead paste can be produced from the paste machine, and this lead paste can be coated. 6-QW-60 battery is produced in combination with ordinary negative plate. The battery with this lead paste measures 20-hour rate capacity of 73.68Ah, and then measures the discharge voltage at -18°C and 280A: 9.91V for 30s; 9.4 for 150s V; another 20-hour rate capacity was measured to be 72.63Ah, and then the battery life te...

Embodiment 2

[0008] Example 2: According to the process and the lead paste prepared in Example 1, the temperature control temperature was changed from 70°C to 80°C, and the temperature control time was 35 minutes to 30 minutes. 6-QW-60 battery is produced in combination with ordinary negative plate, and the 20-hour rate capacity of the battery using this lead paste is 72.50Ah; -18℃, 280A discharge voltage: 9.95V for 30s; 9.45V for 150s; retest A 20-hour rate capacity is 71.41Ah; the battery life test reaches 217 times.

Embodiment 3

[0009] Example 3: According to the process and the lead paste prepared in Example 1, the temperature control temperature was changed from 70°C to 85°C, and the temperature control time was 35 minutes to 25 minutes. 6-QW-60 battery is produced in combination with ordinary negative plate, and the 20-hour rate capacity of the battery using this lead paste is 74.32Ah; -18℃, 280A discharge voltage: 9.83V for 30s; 9.29V for 150s; retest A 20-hour rate capacity is 72.56Ah; the battery life test reaches 208 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com