Sealed rectangular battery

A technology for rectangular batteries and accumulators, applied in the manufacture of airtight accumulators, alkaline accumulators, and alkaline accumulators, etc., can solve the problems of the influence of the connection part, weak strength, and increase in the internal pressure of the battery slot 52, so as to suppress the expansion and deformation. , to ensure the effect of installation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

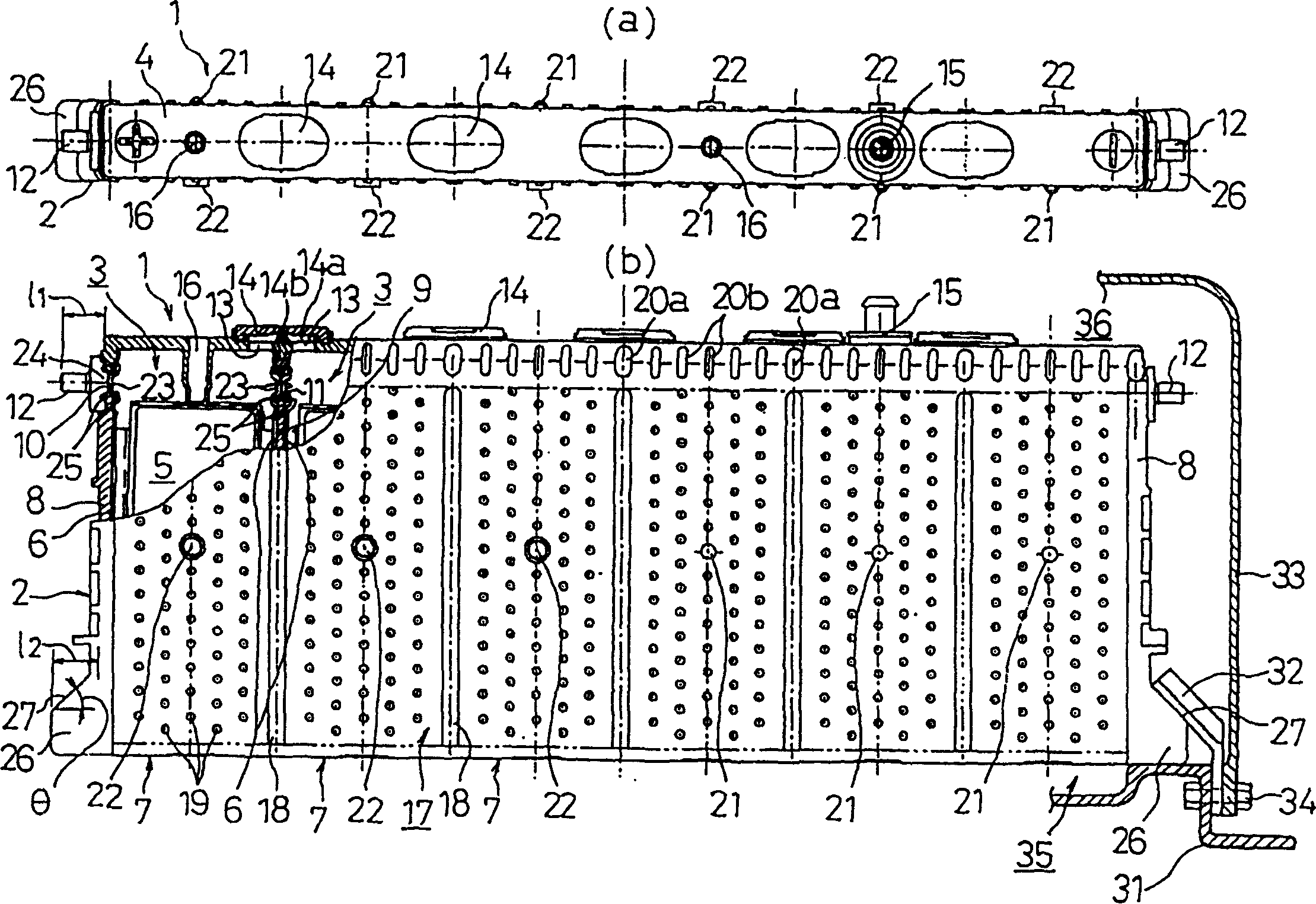

[0033] Refer to the following Figure 1-Figure 5 One embodiment of the sealed rectangular storage battery of the present invention will be described.

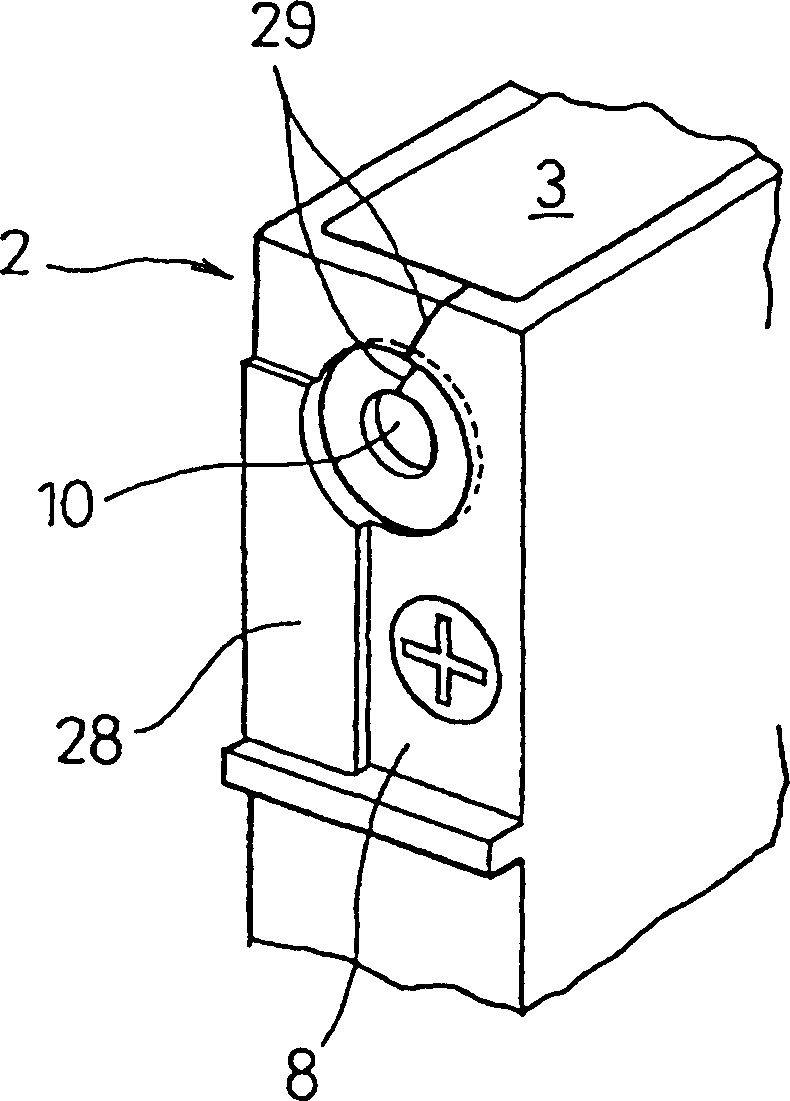

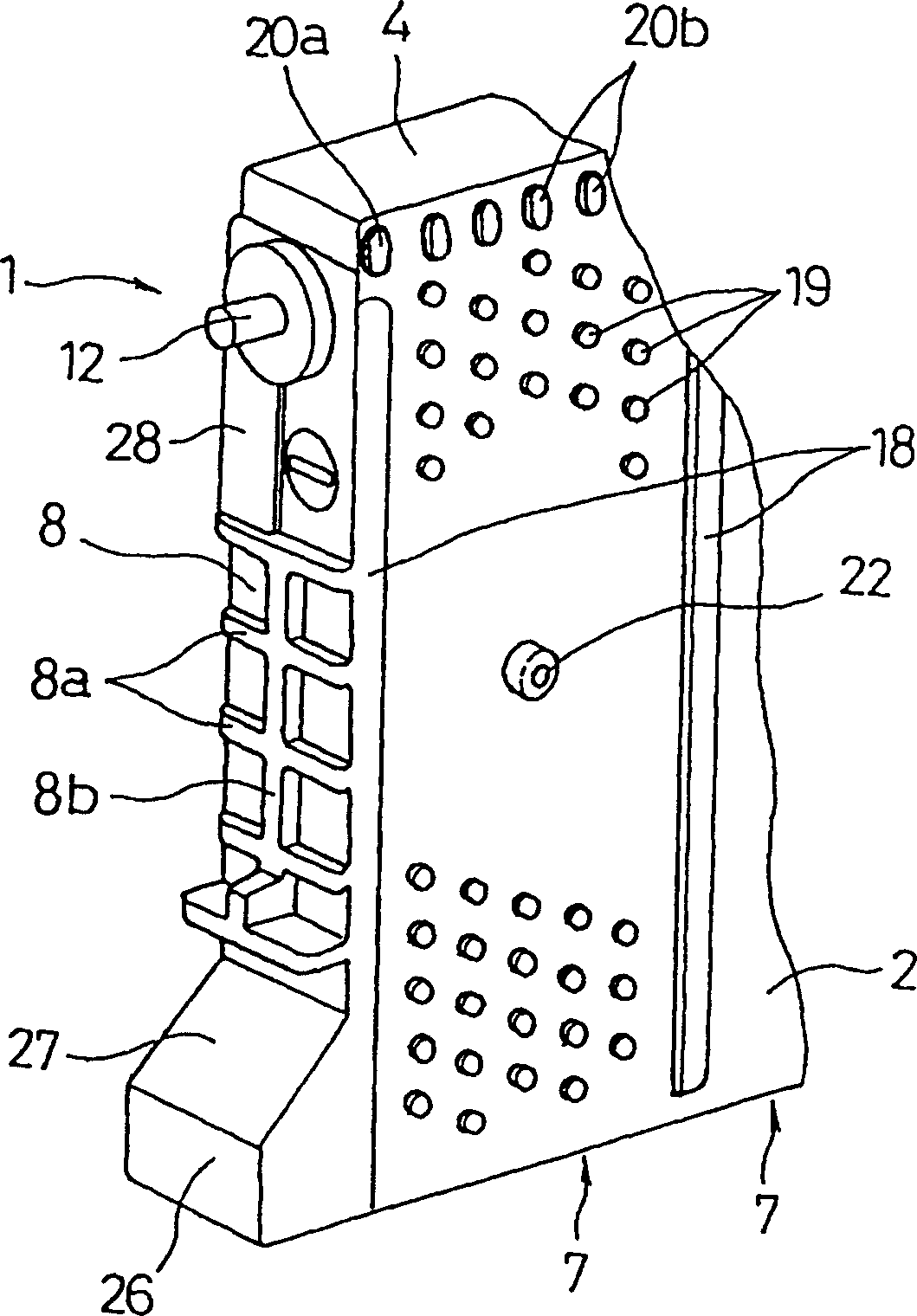

[0034] The sealed rectangular storage battery 1 of the present embodiment is made of a nickel-metal hydride secondary battery suitable for a driving power source of an electric vehicle, such as figure 1As shown, the short sides of a plurality of (6 in the figure) battery slots 3 in the shape of a cuboid having a narrow short side and a long long side with a long width and upper openings share a flat rectangular integrated battery slot 2 integrally connected to each other. , and the upper opening of each battery chamber 3 is integrally closed by an integral cover body 4 .

[0035] A plurality of positive plates and negative plates parallel to the long side of the battery case 3 are placed in each battery case 3, and the electrode plate group 5 stacked in the direction of the short side with an interlayer interposed therebetwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com