Mixer systems

A kind of technology of equipment, catheter, applied in the field of mixing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

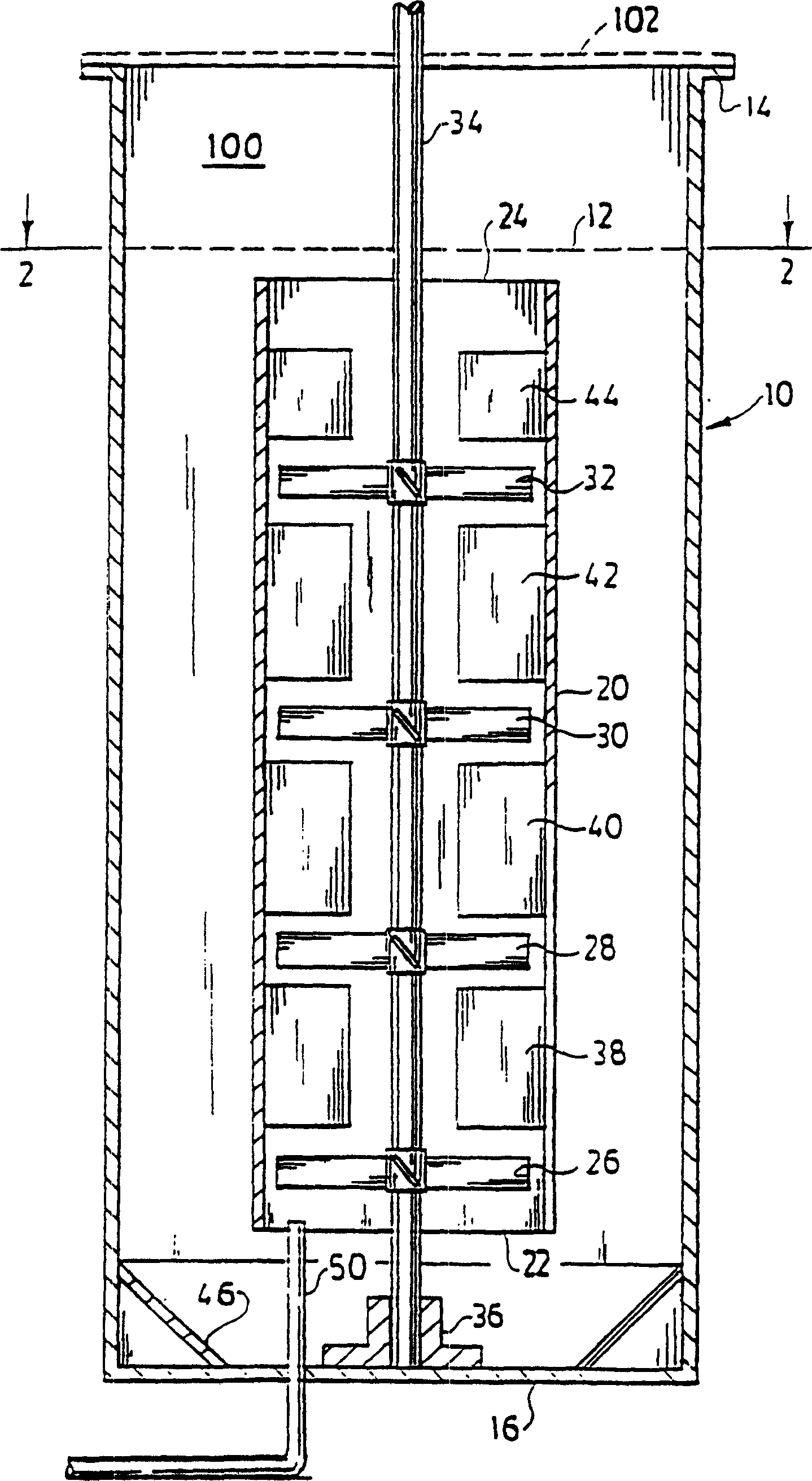

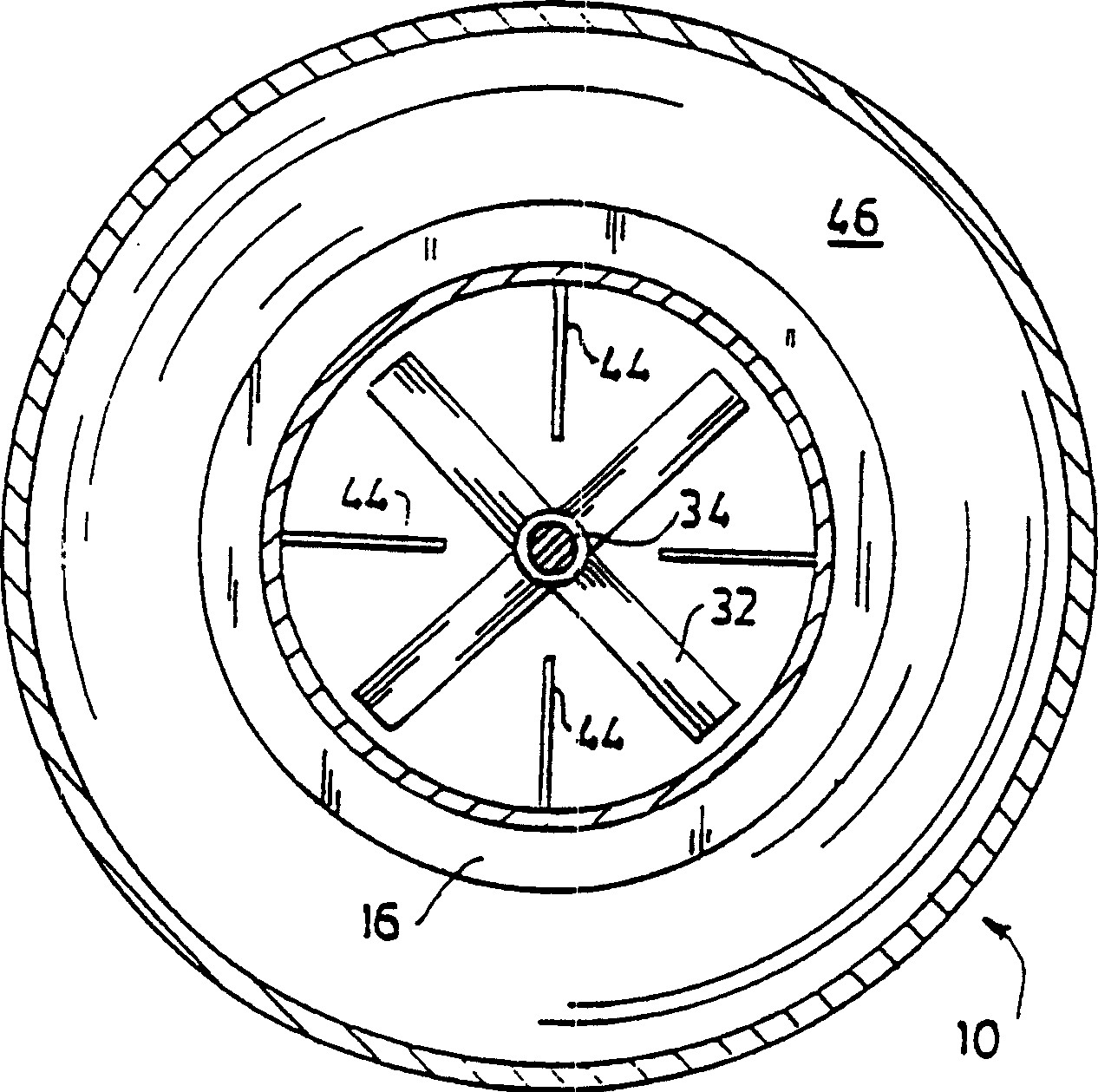

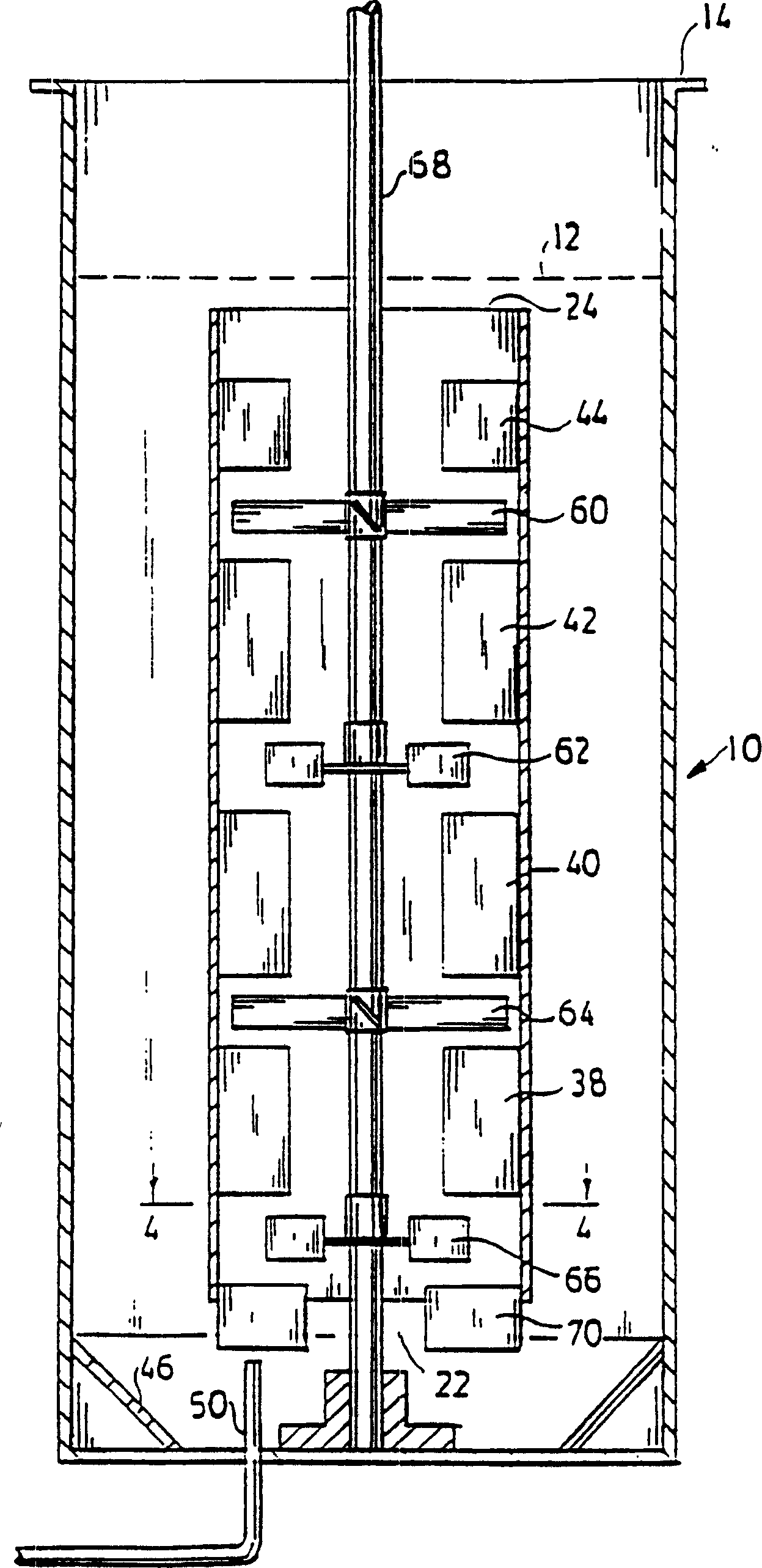

Method used

Image

Examples

example 1

[0085] Conduit diameter 18″

[0086] Groove diameter 36″

[0087] Liquid level 72″

[0088] Tank height 84″

[0089] Input power 23.6HP / kgal

[0090] Jet rate 0.5vvm

[0091] up through the conduit and through

[0092] Downward liquid flow rate in the annular area 3 / 2 liters / second

[0093] The turnover time of the liquid in the whole tank is 3.9 seconds

[0094] Liquid phase throughout the tank volume

[0095] Species transfer coefficient (K L a) 18.9 seconds -1

example 2

[0097] Conduit diameter 24″

[0098] Groove diameter 36″

[0099] Liquid level 72″

[0100] Tank height 84″

[0101] Input power 23.6HP / kgal

[0102] Jet rate 0.5vvm

[0103] up through the conduit and through

[0104] Downward liquid flow rate in the annular area 5 / 6 liters / second

[0105] The turnover time of the liquid in the whole tank is 2.3 seconds

[0106] Liquid phase throughout the tank volume

[0107] Species transfer coefficient (K L a) 16.5hr -1

example 3

[0109] Conduit diameter 18″

[0110] Groove diameter 36″

[0111] Liquid level 72″

[0112] Tank height 84″

[0113] Input power 23.6HP / kgal

[0114] Jet rate 0.1vvm

[0115] up through the conduit and through

[0116] Downward liquid flow rate in the annular area 444 l / s

[0117] The turnover time of the liquid in the whole tank is 2.7 seconds

[0118] Liquid phase throughout the tank volume

[0119] Species transfer coefficient (K L a) 10.3 hours -1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com