High sealing hot belt type packaging aluminium

A high-sealing, tropical-type technology, applied in the field of packaging materials, can solve the problem of high cost, achieve good sealing, not easy to break, and slow down the damage caused by lattice slip deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

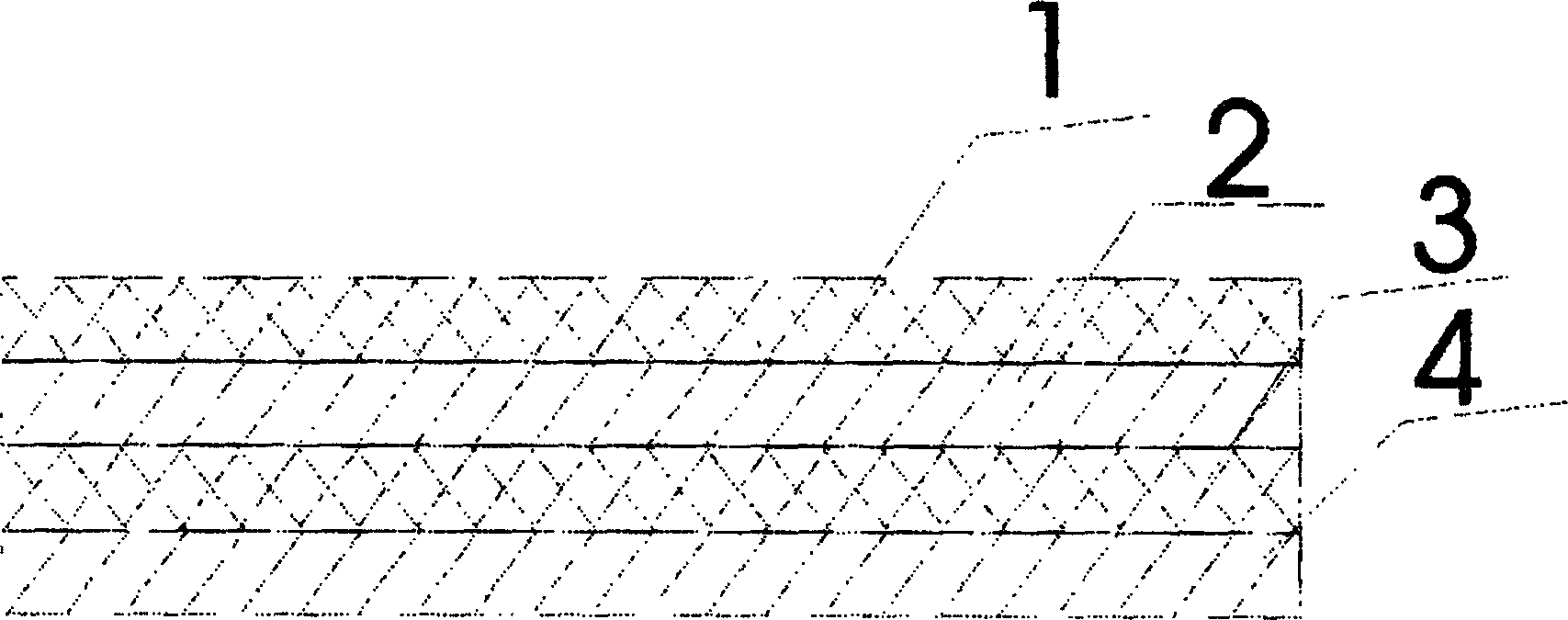

[0009] figure 1 Shown is a packaging material compounded by a dry compounder. Because the domestic major aluminum factories can produce aluminum foil sheets with more than 8 wires, the surface is very rough, there are too many color spots, uneven, there are bubbles in the plastic-aluminum compounding process, the compounding is not tight enough, and the surface quality and appearance are very ugly. Moreover, the toughness and tensile strength cannot meet the requirements. Considering that aluminum foil is metal, metal and metal cannot be directly combined with high density without tension and toughness. Therefore, the first layer can be composited with nylon PA and aluminum foil, and a variety of plastic-aluminum interlayers can be used for bonding with high-temperature, high-viscosity materials whose color can meet the requirements after plastic-aluminum composite. The middle adhesive layer can be one or more layers, and its material can be plastic and aluminum foil with hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com