Heat insulating quartzite brick for outer wall decoration

A technology for sand exterior walls and thermal insulation bricks, applied in the field of building components, can solve the problems of increased cost, time-consuming and labor-intensive, and large proportion of bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

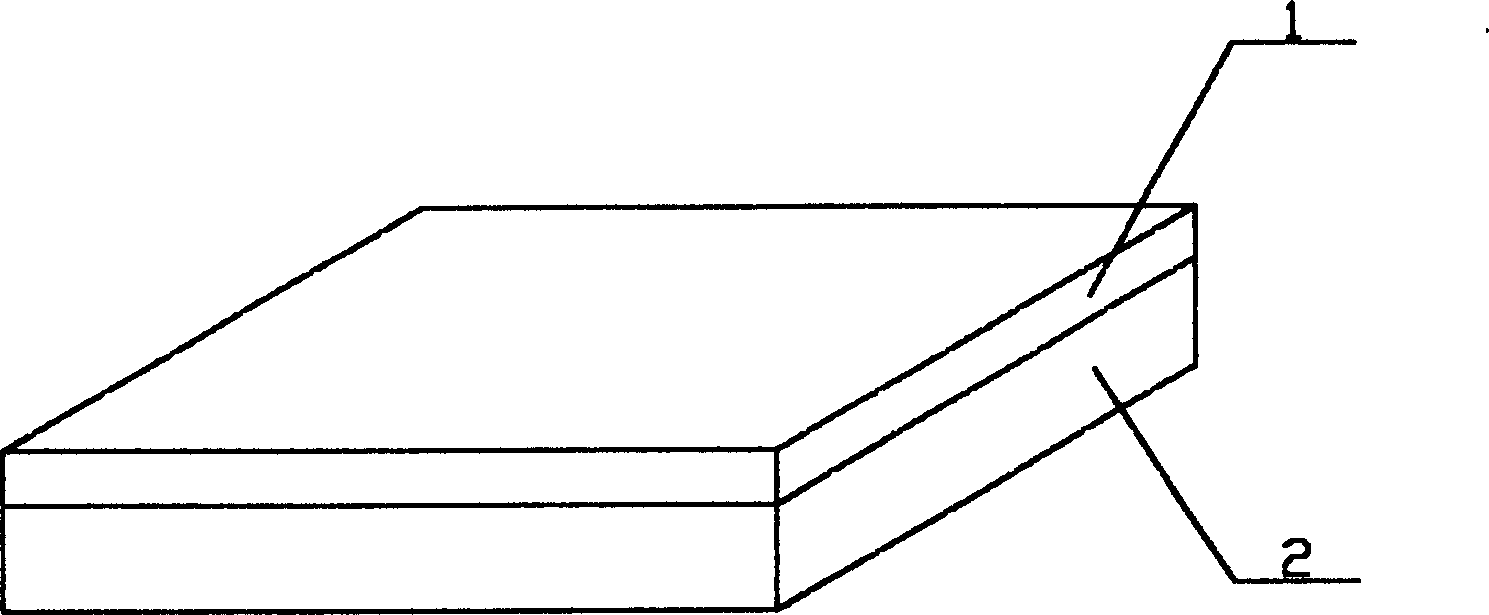

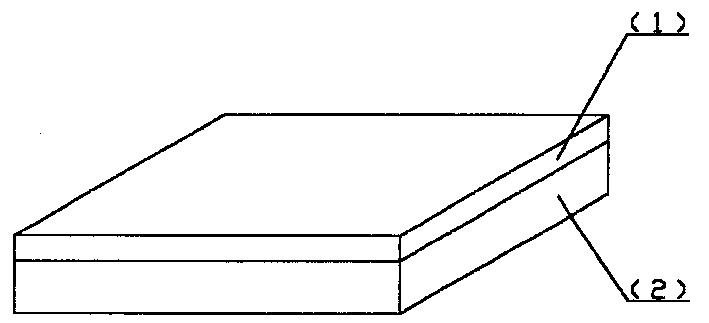

[0005] Embodiment 1: This embodiment includes a fabric layer 1 and a base material layer 2. The fabric layer is made of colored cement, quartz sand and fine sand, and they account for the following proportions by weight percentage: colored cement 20-30, quartz sand Sand 1-55, fine sand 15-79, the bottom material layer is made of cement, ceramsite and sand, by weight percentage, cement 17-25, ceramsite and sand 75-83, the thickness of the fabric layer is 8 -12mm, the thickness of the primer layer is 15-25mm.

specific Embodiment approach 2

[0006] Specific embodiment two: the difference between this embodiment and specific embodiment one is that they respectively account for the following proportions by weight percentage: colored cement 26-27, quartz sand 2-13, fine sand 61-72, and the bottom material layer is In terms of weight percentage, cement 18-20, ceramsite and sand 80-82. The thickness of the fabric layer is 8-10mm, and the thickness of the bottom material layer is 15-20mm.

specific Embodiment approach 3

[0007] Specific embodiment three: The difference between this embodiment and specific embodiments one and two is that they account for the following proportions by weight percentage: colored cement 27.5-28.5, quartz sand 14-36, fine sand 36-58, the base material The layer is made of cement, ceramsite and sand, by weight percentage, cement 21-22, ceramsite and sand 78-79.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com