Apparatus and method of preparing titanium tetrachloride by chlorination of titanium-containing mineral

A technology of titanium tetrachloride and preparation device, applied in chemical instruments and methods, titanium halide, chemical/physical process, etc., can solve the problems of difficulty in scale-up, harsh raw material requirements, environmental pollution, etc., to expand the variety of raw materials and eliminate stickiness. The effect of reducing risk and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

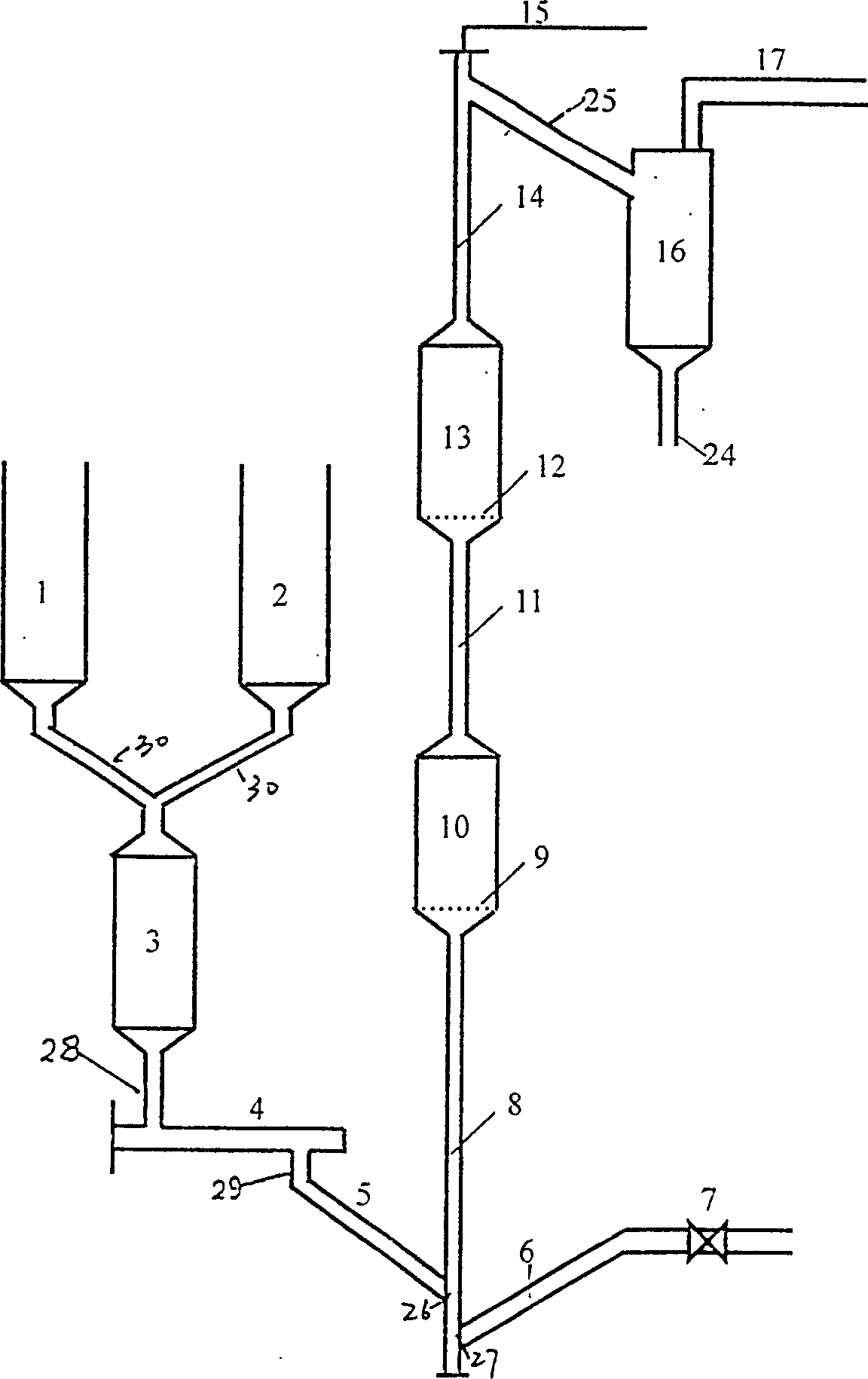

[0033] according to figure 1 , Figure 2 and image 3 A set of equipment for preparing titanium tetrachloride by chlorination of titanium-containing minerals is prepared.

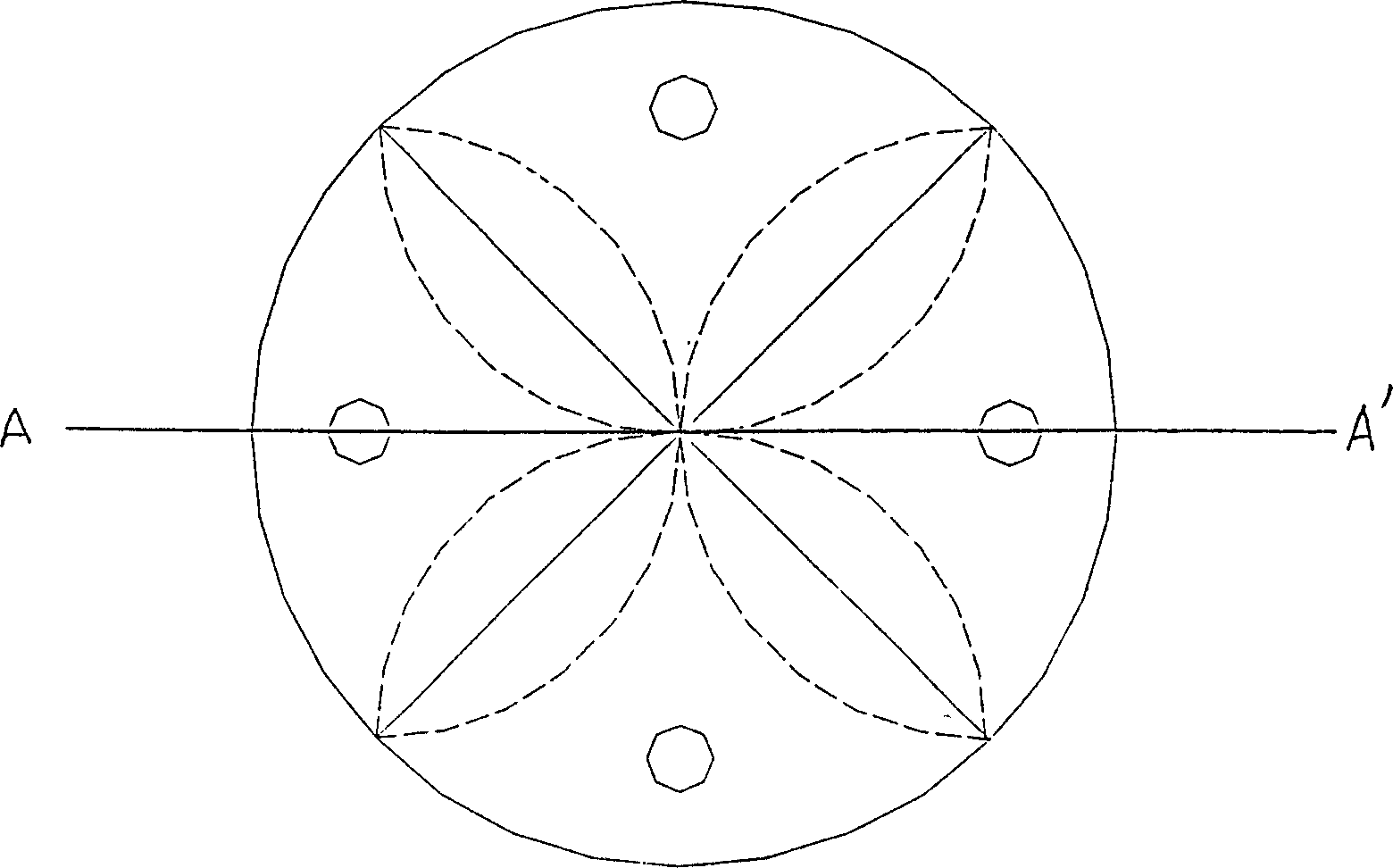

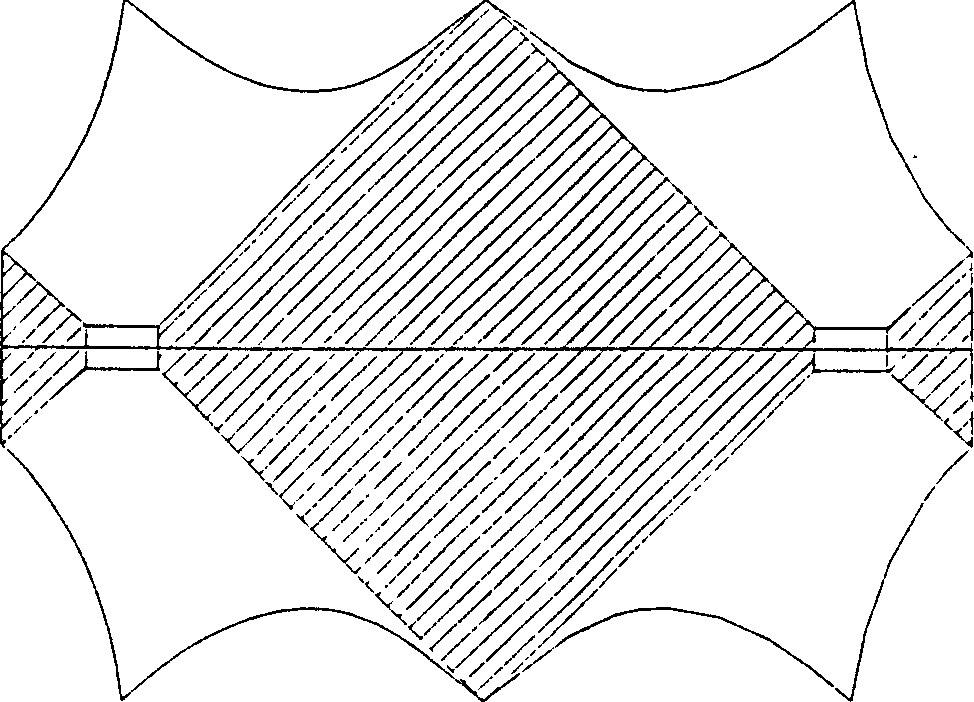

[0034] First, make a group of holes with a ratio of 0.2 and a hole diameter of 15mm according to Figure 2; the center thickness of the distribution plate is 100mm, and the thickness of the hole is 5mm; the distance between the center of the hole and the center of the distribution plate is 70mm; the apex angle of the conical surface is 50° The stainless steel distribution plate 9,12.

[0035] press again figure 1 with image 3 , using the existing fast reaction fluidized bed and turbulent fluidized bed in the market alternately in series to make a 3-stage reaction bed, the distribution plates 9,12 are arranged at the entrances of the turbulent fluidized bed 10,13, and the turbulent fluidized bed 10,13 The inner diameter of the fluidized bed is 200mm, the inner diameter of the fast-reaction fluidized bed i...

Embodiment 3

[0047] according to figure 1 , Figure 2 and image 3 A set of equipment for preparing titanium tetrachloride by chlorination of titanium-containing minerals is prepared.

[0048] First, make a group of openings according to Figure 2 with a ratio of 0.4 and a diameter of 50 mm; the center thickness of the distribution plate is 400 mm, and the thickness of the opening is 15 mm; the distance between the center of the hole and the center of the distribution plate is 200 mm; the apex angle of the conical surface is 150° stainless steel distribution plate.

[0049] press again figure 1 with image 3 , using the existing fast fluidized bed and turbulent fluidized bed alternately connected in series to make a 10-stage reaction bed, the distribution plate is set at the entrance of the turbulent fluidized bed, the inner diameter of the turbulent fluidized bed is 600mm, and the fast reaction fluidized bed The inner diameter of the bed is 140mm and the height of the unit is 42m.

[0...

Embodiment 5

[0061] according to figure 1 , Figure 2 and image 3 A set of equipment for preparing titanium tetrachloride by chlorination of titanium-containing minerals is prepared.

[0062] First make a set of opening ratio as shown in Figure 2, the diameter of the hole is 25mm; the center thickness of the distribution plate is 200mm, and the thickness of the opening is 10mm; the distance between the center of the hole and the center of the distribution plate is 170mm; the apex angle of the conical surface is 100° stainless steel distribution plate.

[0063] press again figure 1 with image 3, using the existing fast-reaction fluidized bed and turbulent fluidized bed alternately connected in series to make a 5-stage reaction bed, the distribution plate is set at the entrance of the turbulent fluidized bed, the inner diameter of the turbulent fluidized bed is 400mm, and the fast-reaction fluidized bed The inner diameter of the bed is 120mm and the height of the device is 28m.

[0064...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com