Malonic ester blocked HDI trimer with IPDA stabilization and formaldehyde stabilization

A polyisocyanate and formaldehyde technology, applied in the use of 1-amino-3, can solve the problems of insufficient prevention of turbidity and precipitation, and achieve the effects of less thermal yellowing, reduced thermal yellowing, and good coating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

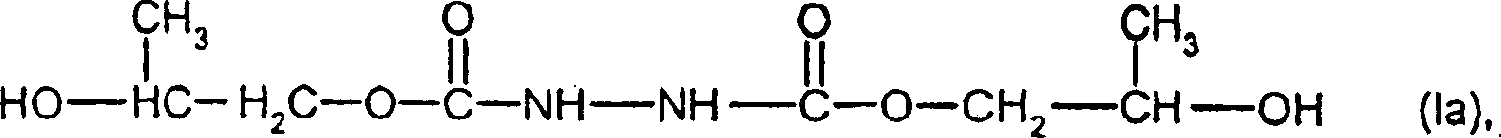

Image

Examples

Embodiment 1

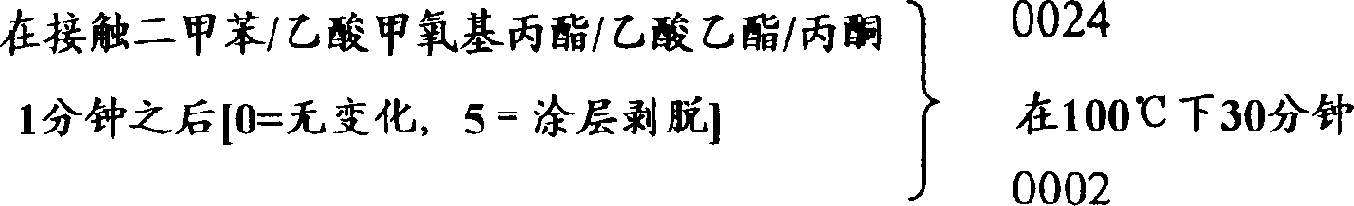

[0043] Embodiment 1 (according to the present invention)

[0044] The blocked polyisocyanate crosslinker described herein has an IPDA content of 2.32 wt% and a formaldehyde content of 2.46 wt%, on a solids basis.

[0045] Element

[0046] 196.0g based on having an NCO content of 21.4wt%, at

[0047] Viscosity at 23°C is about 3000mPas

[0048] The content of 1,6-diisocyanatohexane (HDI)

[0049] Isocyanurate Coating Polyisocyanate

[0050] 152.0g (0.95mol) diethyl malonate

[0051] 3.0g 30% solution of sodium methoxide in methanol

[0052] 8.5g 3,3,5-trimethyl-5-aminomethylcyclohexylamine

[0053] (IPDA)

[0054] 9.0g (0.30mol) paraformaldehyde

[0055] 0.9g 30% solution of sodium methoxide in methanol

[0056] 40.6g N-methylpyrrolidone (NMP)

[0057] 40.6g isobutanol (IB)

[0058] 40.6g butyl glycol (BG)

[0059] 4.8g dibutyl phosphate

[0060] 496.0g

[0061] ...

Embodiment 2

[0068] Embodiment 2 (comparative example)

[0069] The crosslinker was again prepared as in Example 1 with the following changes: 8.5 g of IPDA was omitted and 16.0 g of diethyl malonate was used instead. The crosslinker became cloudy after 7 days of storage at room temperature, but remained liquid.

Embodiment 3

[0070] Embodiment 3 (comparative example)

[0071] The crosslinker was again prepared as in Example 2 with the following changes: No formaldehyde was introduced. Compared to the crosslinker of Example 1, IPDA and formaldehyde are therefore absent.

[0072] After 3 days of storage at room temperature, the crosslinker cured to a glass-like, transparent composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com