Polymerizable composition and plated printed plate fore-body

A technology of lithographic printing plate and polymer composition, applied in lithographic printing equipment, printing, printing process and other directions, can solve problems such as low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

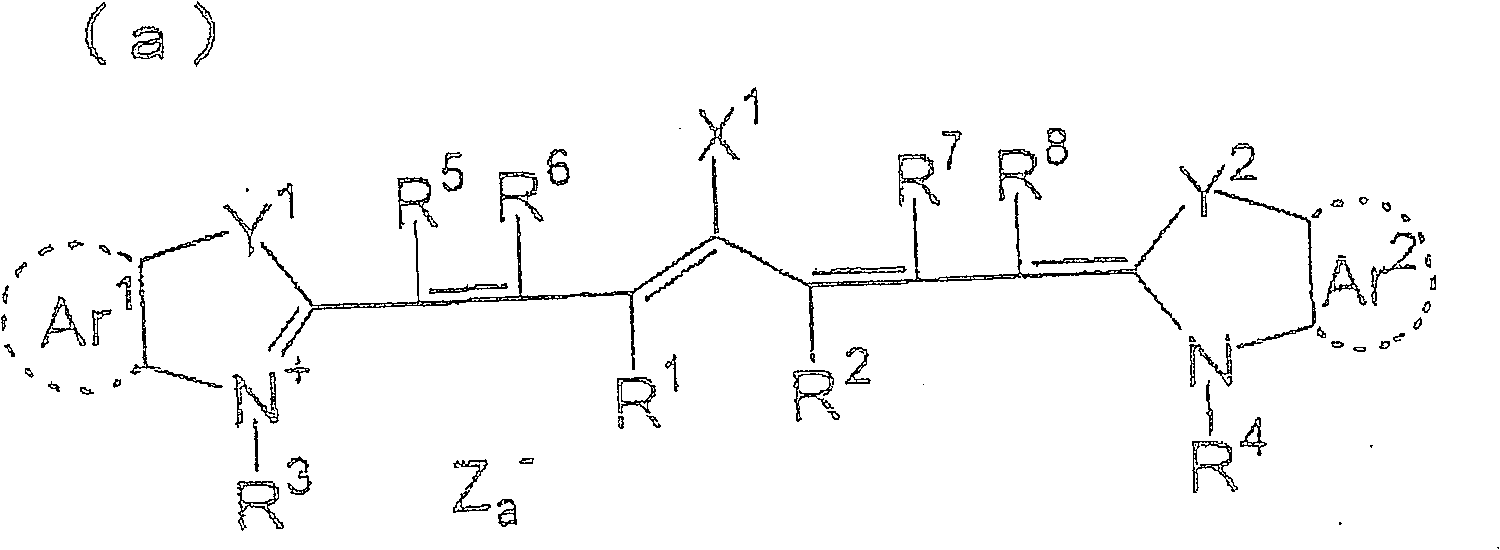

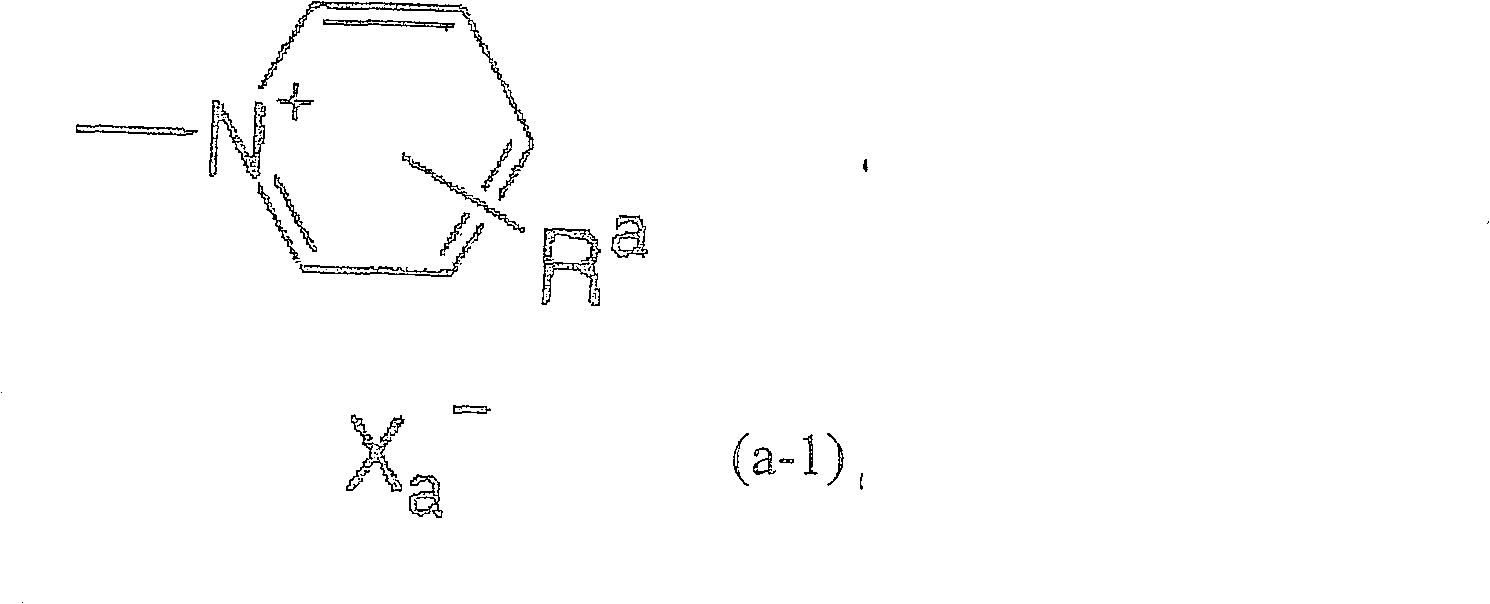

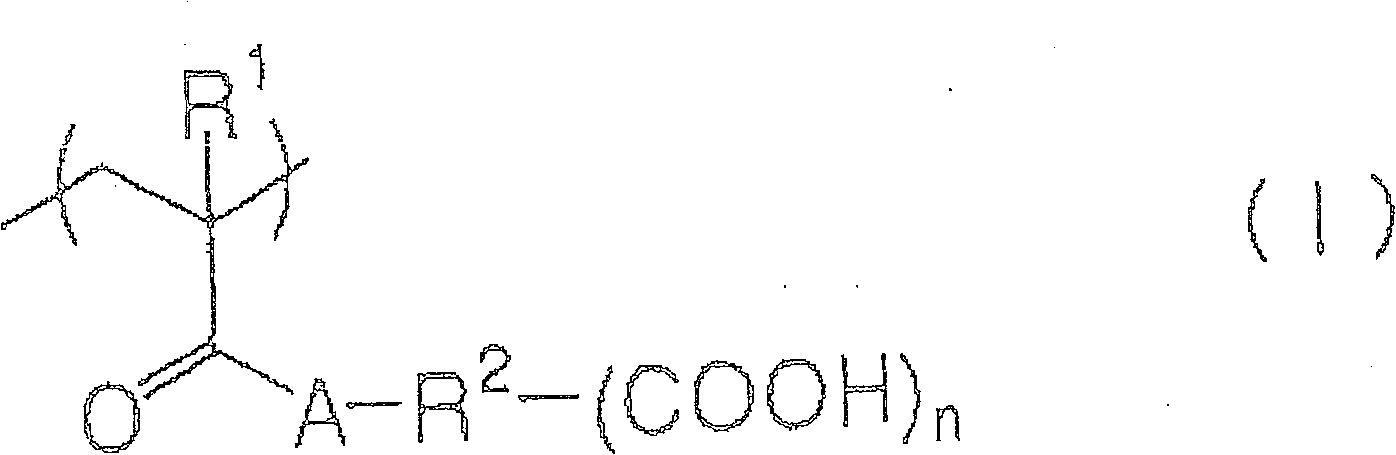

Method used

Image

Examples

Embodiment 1

[0059] (Synthesis Example 1: Synthesis of Example Compound B-20)

[0060] 1. Synthesis of three (4-chlorophenyl) sulfonium bromide

[0061] Under a nitrogen atmosphere, 16.3 g (0.06 mol) of bis(4-chlorophenyl)sulfoxide was dissolved in 250 ml of dichloromethane. To the resulting solution kept at 0 to 5°C, 10.8 g (0.10 mol) of trimethylchlorosilane was added dropwise; the mixture was stirred at 0°C for 30 minutes. Then, to the reaction vessel cooled with ice water at 0 to 10°C, a solution of Grignard's reagent in tetrahydrofuran (THF) (prepared by a conventional method using 4-bromochlorobenzene (0.18 mol)) was added within 30 minutes. After stirring at 0°C for 1 hour and at room temperature for another hour, the reaction solution was slowly poured into an aqueous solution containing 250 ml of 12% aqueous hydrogen bromide and ice water, and then extracted with 250 ml of dichloromethane. The extract was dried over sodium sulfate.

[0062] After removal of the solvent, 100 ml ...

Embodiment 2

[0065] (Synthesis Example 2: Synthesis of Example Compound B-17)

[0066] To an aqueous solution of 4.60 g of sodium dinaphthalenesulfonate dissolved in 100 ml of distilled water was poured 4.46 g of tris(4-chlorophenyl)sulfonium bromide prepared above and dissolved in 50 ml of dichloromethane, and the mixture was stirred for 1 hour. The organic layer was extracted and washed with 100 ml of water. After drying over sodium sulfate, the organic layer was concentrated. To the concentrated organic layer, 100 ml of ethyl acetate was poured. The mixture was stirred at reflux for 30 minutes. After cooling, the organic layer was filtered and washed with ethyl acetate. The filtrate was dried under vacuum at 40°C for 6 hours to give 5.07% solid (88% yield) containing 5.7% by weight ethyl acetate. Confirmed by NMR analysis, the solid proved to be Example Compound (B-17).

[0067] In the case of being used in the recording layer of a lithographic printing plate precursor, the content...

Embodiment 1 to 12

[0353] [Composition of base material]

[0354] An aluminum sheet (material 1050) with a thickness of 0.3 mm was cleaned with trichlorethylene and degreased. Then use a nylon brush and a 400-mesh pumice to sandblast and etch the surface of the aluminum sheet. After rinsing with water, soak in 20% nitric acid for 20 seconds, and then rinse with water. The etchant dose on the sandblasted surface is 3g / m 2 .

[0355] Then use 7% sulfuric acid as electrolyte at 15A / dm 2 A current density of 3g / m is formed on the sheet 2 The oxide film of the direct current electrode is then rinsed with water and dried to obtain the substrate (A).

[0356] Substrate (A) was treated with 2% (mass) sodium silicate solution at 25° C. for 15 seconds, and washed with water to obtain another substrate (B).

[0357] [Formation of the middle layer]

[0358] The liquid composition (sol) for the SG method was then prepared in the following manner.

[0359]

[0360] ·Methanol 130g

[0361] ·Water 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| atomic number | aaaaa | aaaaa |

| optical density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com