Magnetic suction precision sowing method and its equipment

A precision seeding and magnetic suction technology, which is applied to the parts of planters, etc., can solve the problems of high manufacturing cost and technical requirements, easy blockage of suction pipes or suction holes, high requirements for shape, etc., and achieve low manufacturing cost , wide application range and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

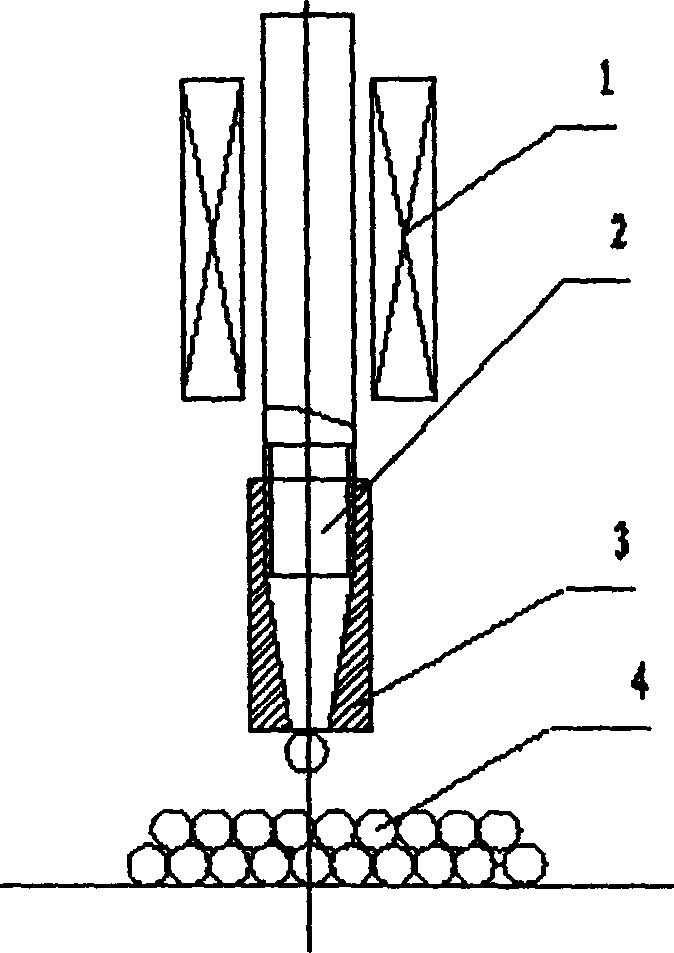

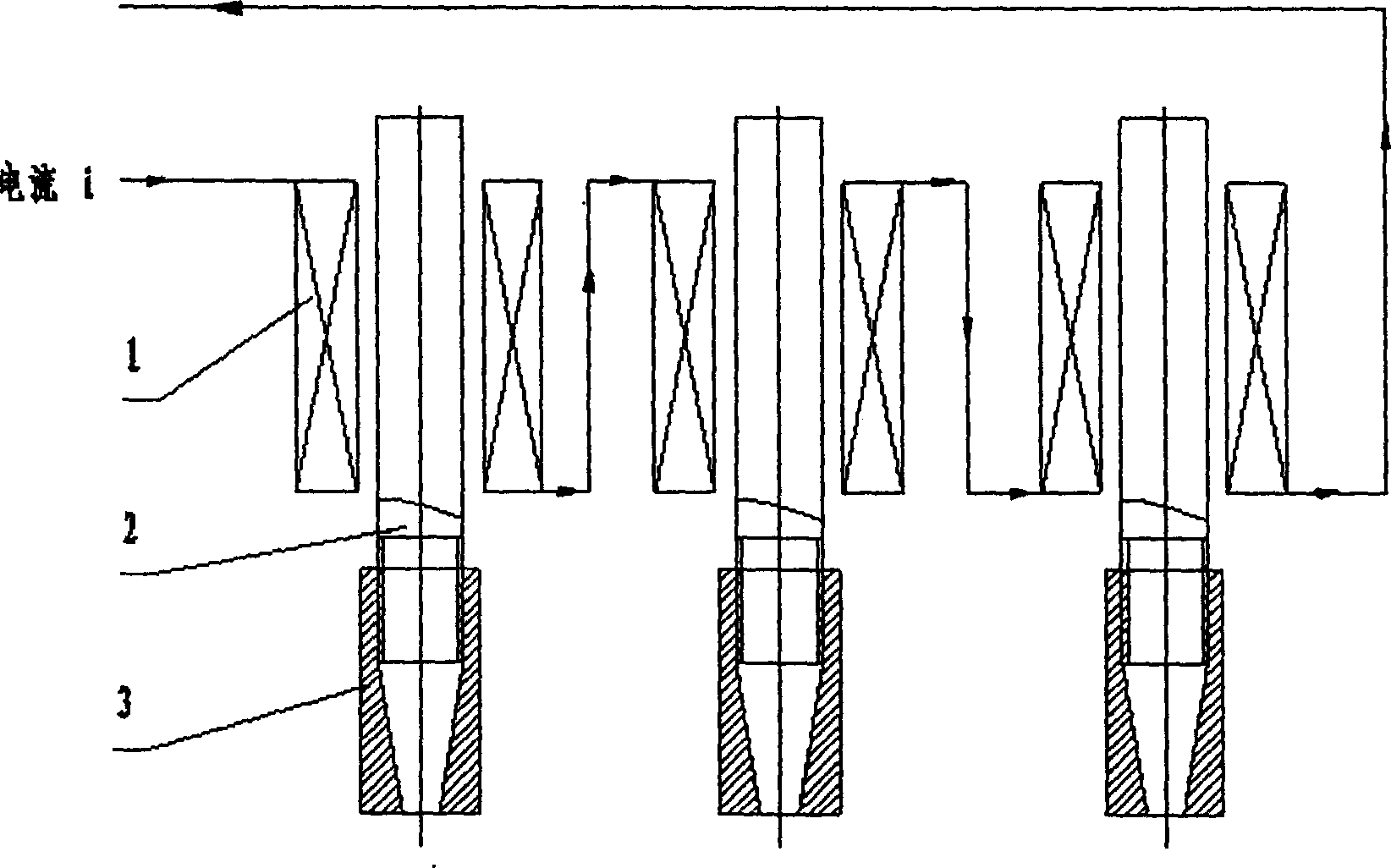

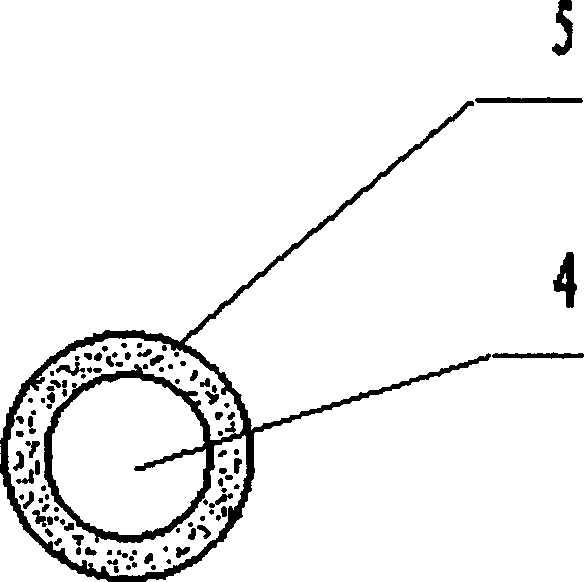

[0015] Such as figure 1 Shown, form a magnetic suction type seed picker (10) by electromagnetic coil (1), magnetic suction head (2), diamagnetic sleeve pipe (3), magnetic suction head (2) is columnar iron core, gives electromagnetic coil (1) is connected with a certain current to generate a certain magnetic field at the lower end of the magnetic suction head (2). Overcoming the gravity of the seeds, the seeds are sucked up and attached to the lower end of the magnetic suction head (2); when the magnetic suction head (2) moves above the hole of the tray, the current in the electromagnetic coil (1) is cut off, the electromagnetic field disappears, and the magnetic suction There is only weak residual magnetic field left in the head (2), and the residual magnetic field force is not enough to overcome the self gravity of the seed, so the seed (4) will fall, and currents of different sizes are passed to obtain magnetic field forces of different sizes. The material of the magnetic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com