A kind of gold cyanide-free electroforming liquid, preparation method and electroforming method

A technology of electroforming liquid and gold, which is applied in the direction of electroforming and electrolysis, which can solve the problems of environment and operator threats, and achieve the effect of high electroforming brightness, easy preparation and stable solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment discloses a gold cyanide-free electroforming solution, including: 50-70g / L ammonium sulfite, 100-125g / L ammonium sulfate, 25-55g / L disodium edetate, 85 -115g / L potassium citrate, 70-100g / L potassium chloride, 0.5-1g / L dinitrosophenol, 1-1.5g / L butynediol, 1-2g / L ortho The gold content in benzoylsulfonimide and 5-15g / L gold sodium sulfite.

[0041] The gold cyanide-free electroforming solution of the present invention does not contain highly toxic cyanide, the formula is simple, easy to prepare, the solution is stable, and the waste liquid is easy to recycle. Therefore, the gold cyanide-free electroforming solution is safe and environmentally friendly.

[0042] 50g of ammonium sulfite, 100g of ammonium sulfate, 25g of disodium edetate, 85g of potassium citrate, 70g of potassium chloride, 0.5g of dinitrosophenol, 1g of butynediol, 1.5 The gold content in 1 g of o-benzoylsulfonimide and 5 g of gold sodium sulfite is configured to form an electroplating so...

Embodiment 2

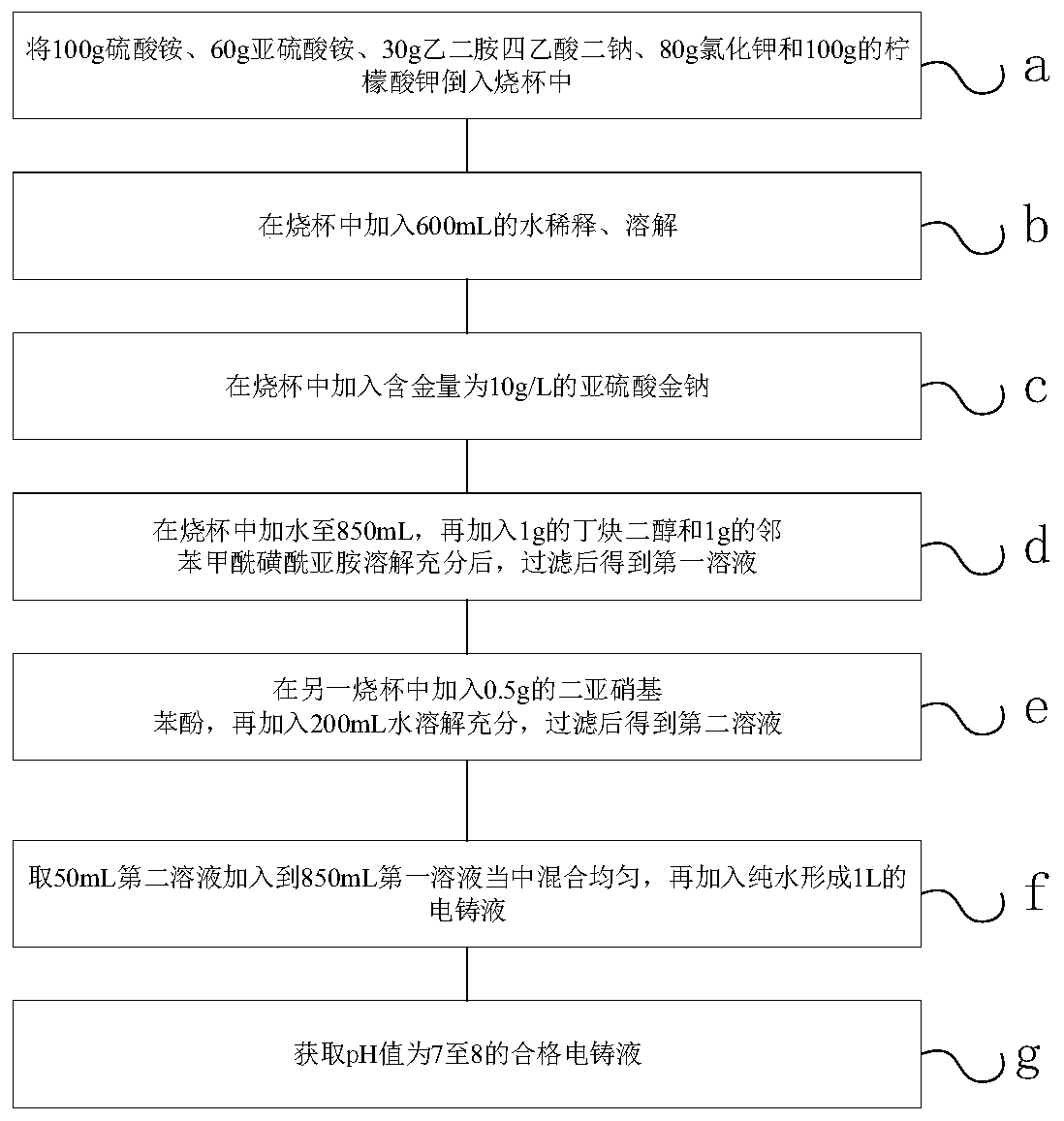

[0047] Such as figure 1 As shown, according to another embodiment of the present invention, a kind of preparation method of gold cyanide-free electroforming solution is provided, comprising the steps:

[0048] a. Pour the potassium citrate of 100g ammonium sulfate, 60g ammonium sulfite, 30g edetate disodium, 80g potassium chloride and 100g into the beaker;

[0049] b. Add 600mL of water to the beaker to dilute and dissolve;

[0050] C, add the gold sodium sulfite that gold content is 10g / L in the beaker;

[0051]d. Add water to 850mL in the beaker, then add 1g of butynediol and 1g of o-benzoylsulfonimide to fully dissolve, and filter to obtain the first solution;

[0052] e. Add 0.5g of dinitrosophenol into another beaker, then add 200mL of water to dissolve fully, and obtain the second solution after filtration;

[0053] f. Add 50mL of the second solution to 850mL of the first solution and mix evenly, then add pure water to form a 1L electroforming solution;

[0054] g. O...

Embodiment 3

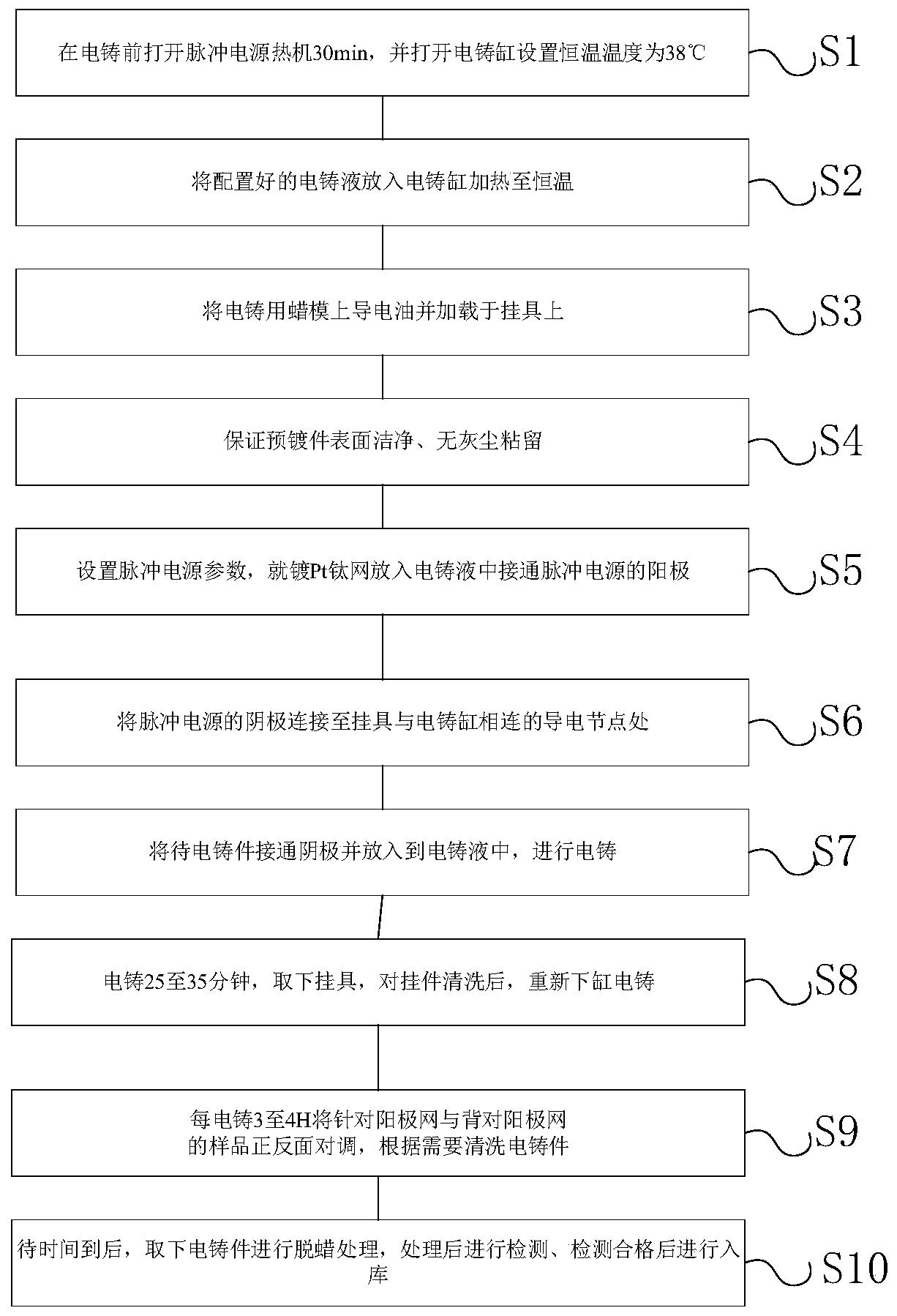

[0062] Such as figure 2 As shown, according to another embodiment of the present invention, a kind of electroforming method of gold jewelry gold cyanide-free electroforming solution is provided, comprising the steps:

[0063] S1. Turn on the pulse power supply heat engine for 30 minutes before electroforming, and turn on the electroforming cylinder to set the constant temperature to 38°C;

[0064] S2. Put the configured electroforming liquid into the electroforming cylinder and heat to constant temperature;

[0065] S3. Apply conductive oil to the wax mold for electroforming and load it on the rack;

[0066] S4. Ensure that the surface of the pre-plated parts is clean and free of dust;

[0067] S5, setting the pulse power supply parameters, put the Pt-plated titanium mesh into the electroforming solution and connect the anode of the pulse power supply;

[0068] S6. Connect the cathode of the pulse power supply to the conductive node where the hanger is connected to the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com