Combined circulating fluid bed boiler

A circulating fluidized bed and boiler technology is applied in the field of fluidized bed boiler structure and combined circulating fluidized bed boiler structure. Low utilization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

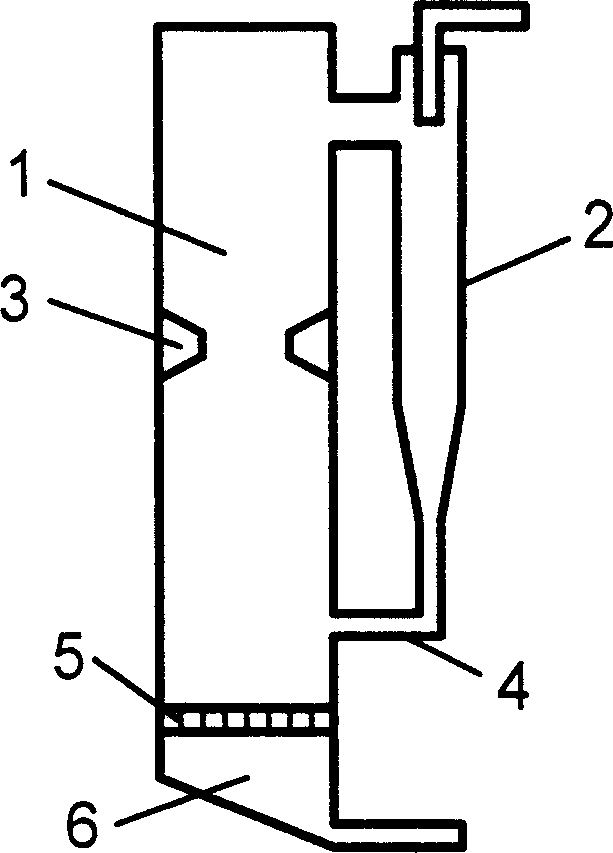

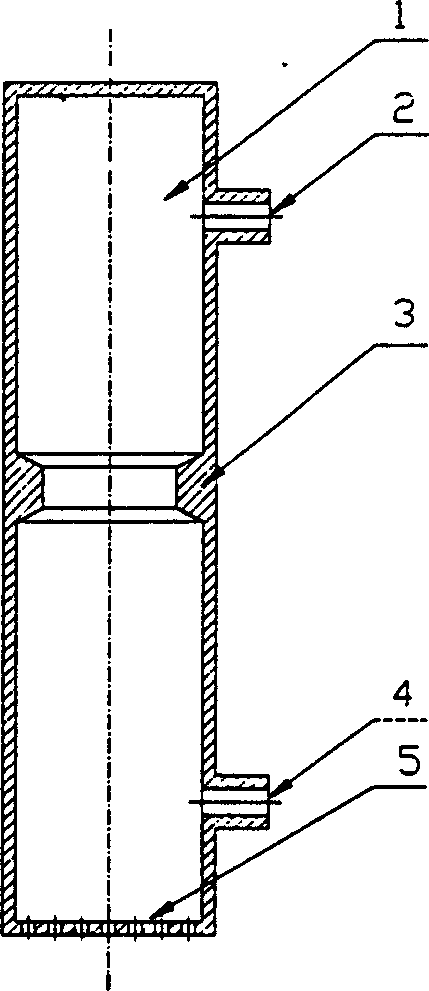

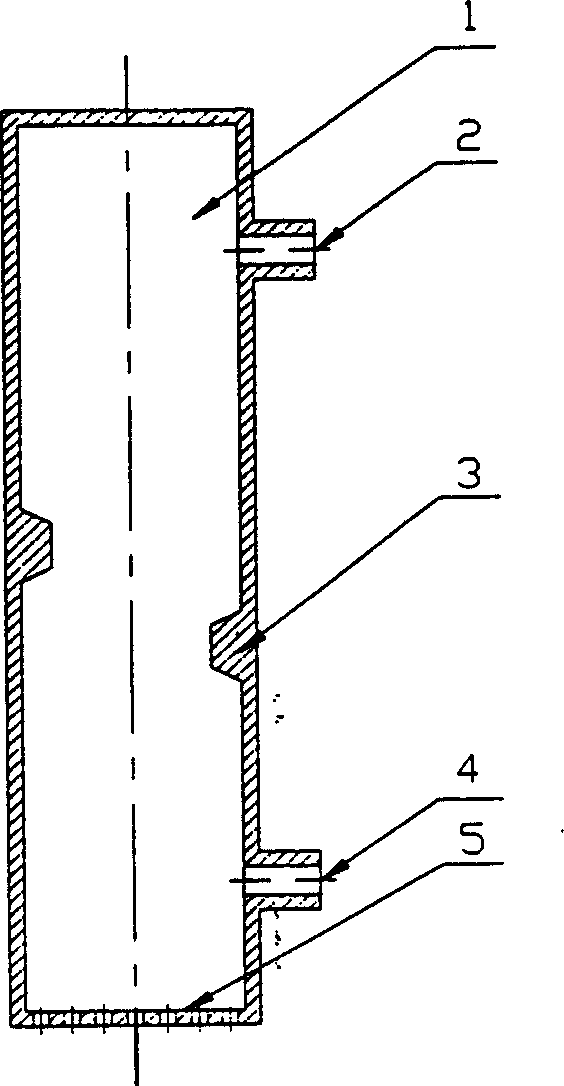

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes: a furnace 1, a cyclone separator 2, a throat 3, a return valve 4, an air distribution plate 5, and an air chamber 6. The specific improvements are as follows: a variety of The throat 3 is formed by the transverse partition wall structure protruding into the furnace, which divides the furnace 1 into several combustion chambers along the height. After adding the throat 3, multiple internal circulations appear in the furnace, and an external circulation is added to form a combined circulation. structure.

[0014] The shape of the throat 1 is various geometric shapes, such as: trapezoidal, rectangular, triangular, semicircular and Laval-shaped. Throat 1 is a single-stage throat or a multi-stage throat with two or more stages, and its positions can be directly opposite or staggered. The multi-stage throat is suitable for large-capacity circulating fluidized bed boilers, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com