Liquid-phase continuous condensation polymerization apparatus of high-viscosity polyester (PET)

A high-viscosity, polyester technology, applied in chemical/physical/physical-chemical stationary reactors, etc., to reduce production costs and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

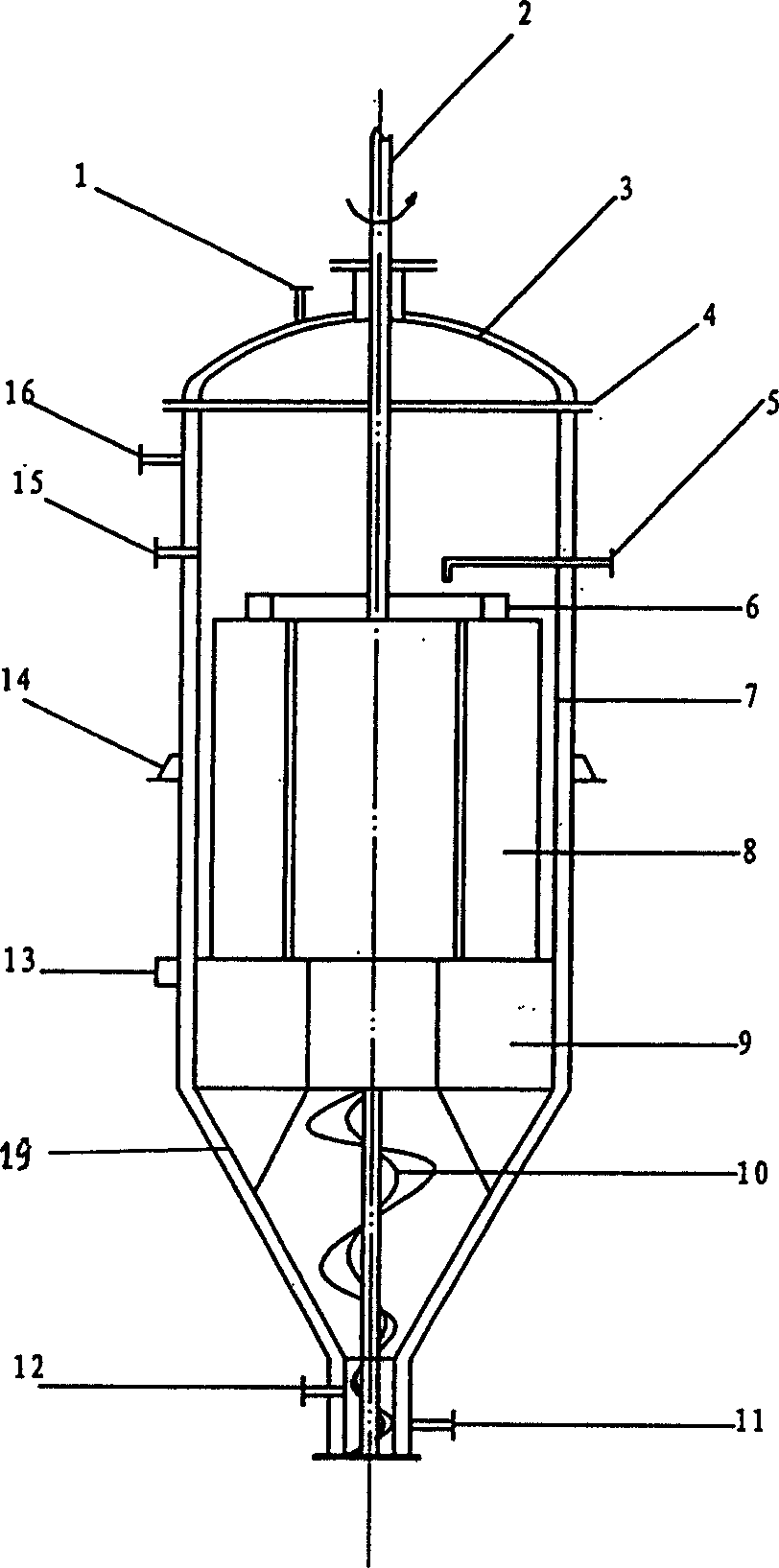

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0026] Manufacture this device according to the manufacture method of chemical container, and connect kettle body 7 and kettle cover 3 by bolt and flange 4, bracket 14 is welded on kettle body 7 and supports kettle body 7, and the biphenyl heating of kettle body 7 periphery is through The heat medium interface 1, 11, 16 enters into the heat medium jacket 19, the inlet and outlet ports 5, 12 are set on the upper and lower parts of the kettle body, the material level gauge 13 is installed on the upper part of the cone body, and the vacuum interface 15 is welded on the devolatilizer upper part. Inside the device, the stirring shaft 2 and rolling bearings are fixed on the bottom and top of the kettle body, and a motor is installed on the top of the kettle. The upper and middle stirring shaft 2 in the kettle body is connected with a planetary carrier 6 by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com