Process for preparing zero-shinkage low-temp, co-fired ceramic multi-layer baseplate

A technology of low-temperature co-fired ceramics and multi-layer substrates, which is applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, electrical components, etc., and can solve problems such as large plane shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

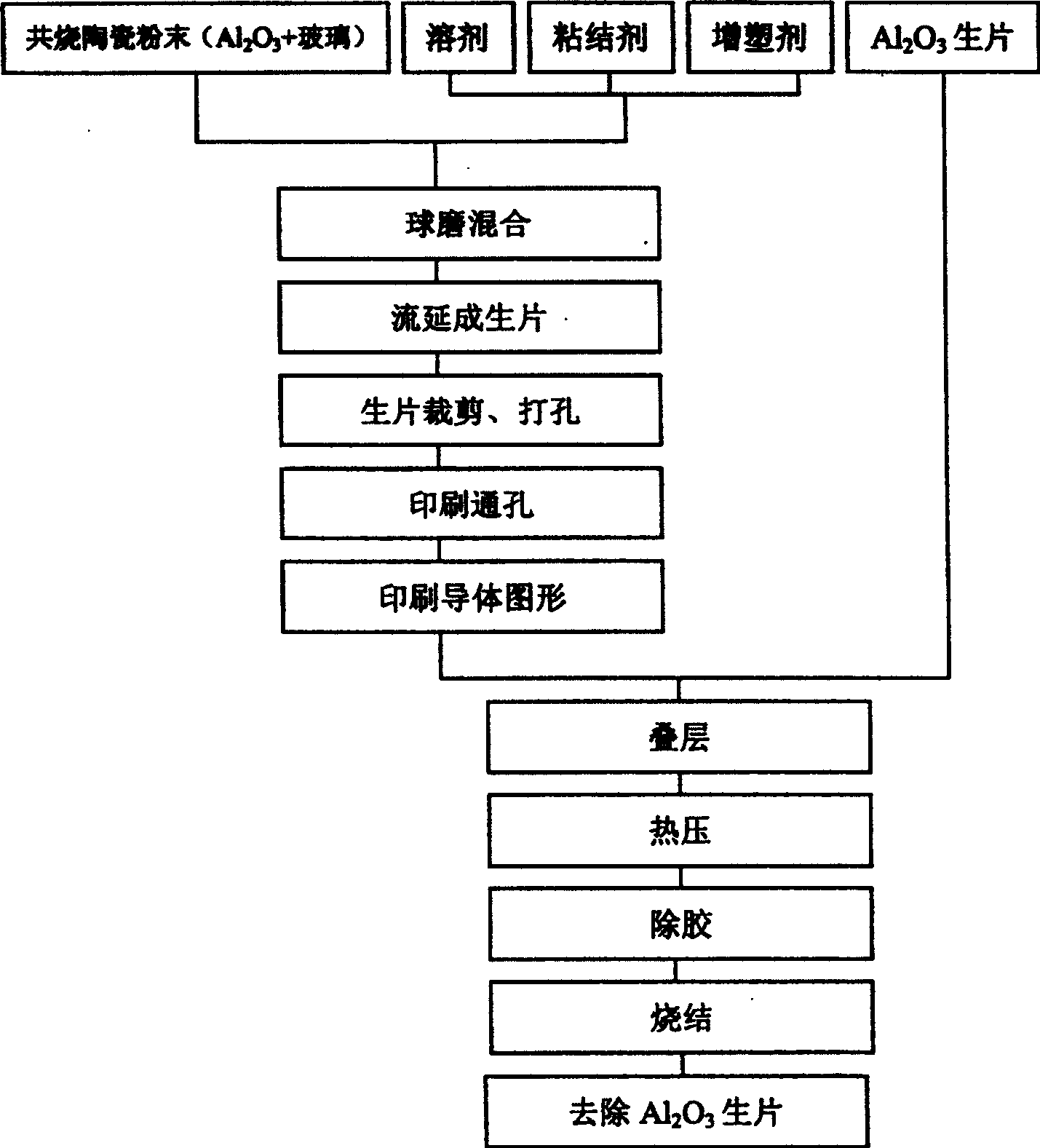

Method used

Image

Examples

Embodiment 1

[0018] (1) Select CaO-Al 2 o 3 -B 2 o 3 -SiO 2 Glass and Al 2 o 3 Powder is made into glass ceramic powder, of which glass accounts for 55% (100.6g), Al 2 o 3 Accounting for 45% (82.0 grams), mixed with binder PVB, plasticizer DBP, solvent toluene, ball milled for 4 hours, and made into slurry;

[0019] (2) casting the slurry into a green sheet with a thickness of 125 μm, cutting it into a square, and punching;

[0020] (3) Print through holes and wiring patterns layer by layer according to the designed pattern. The through-hole conductor paste is Ag-Pd conductor paste, and the inner and outer surface patterns use Ag-Pt conductor paste;

[0021] (4) Laminate 10 green sheets sequentially, and then place an Al layer with a thickness of 0.2 mm on the bottom and top of the stack. 2 o 3 For green sheets, heat press for 1 minute at a temperature of 80°C-100°C and a pressure of 20MPa-25MPa;

[0022] (5) Continue to raise the furnace temperature to 400-450°C at a speed of ...

Embodiment 2

[0027] (1) Glass, Al 2 o 3 Raw material is identical with embodiment 1, and proportioning is different. Of which glass accounted for 45% (81.8 grams), Al 2 o 3 Accounting for 55% (100.2g), mixed with binder PVB, plasticizer DBP, solvent toluene, ball milled for 4 hours, and made into slurry;

[0028] (2) casting the slurry into a green sheet with a thickness of 125 μm, cutting it into a square, and punching;

[0029] (3) Print through holes and wiring patterns layer by layer according to the designed pattern. The through-hole conductor paste is Ag-Pd conductor paste, and the inner and outer surface patterns use Ag-Pt conductor paste;

[0030] (4) Laminate 10 green sheets in turn, and then place an Al with a thickness of 1.2 mm on the bottom and top of the stack. 2 o 3 For ceramic green sheets, keep warm for 1 minute at a temperature of 80°C-100°C and a pressure of 20MPa-25MPa;

[0031] (5) Continue to raise the furnace temperature to 400-450°C at a speed of 2°C / min, ke...

Embodiment 3

[0036] (1) Choose Na 2 O-CaO-B 2 o 3 -SiO 2 Glass and Al 2 o 3 Powder is made into glass ceramic powder, of which glass accounts for 55% (101.1g), Al 2 o 3 Account for 45% (82.3 grams), mix with binder PVB, plasticizer DBP, solvent toluene, ball mill for 4 hours, and make slurry;

[0037] (2) casting the slurry into a green sheet, cutting it into a square, and punching;

[0038] (3) Print through-holes and wiring patterns layer by layer according to the designed pattern, wherein the through-hole conductor paste is Ag-Pd conductor paste, and the inner and outer surface graphics adopt Ag-Pt conductor paste;

[0039] (4) Laminate 10 green sheets in turn, and then place an Al with a thickness of 0.5 mm on the bottom and top of the stack. 2 o 3 The green sheet is hot-pressed at a temperature of 80°C-100°C and a pressure of 15MPa for 1 minute;

[0040] (5) Continue to raise the furnace temperature to 400-450°C at a speed of 3°C / min, keep the temperature for 30 minutes, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com