Assembly for mounting driver IC

A driver and component technology, applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of drive wiring system width and area limitations, and achieve the effects of stable control operation, noise suppression, and line impedance suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

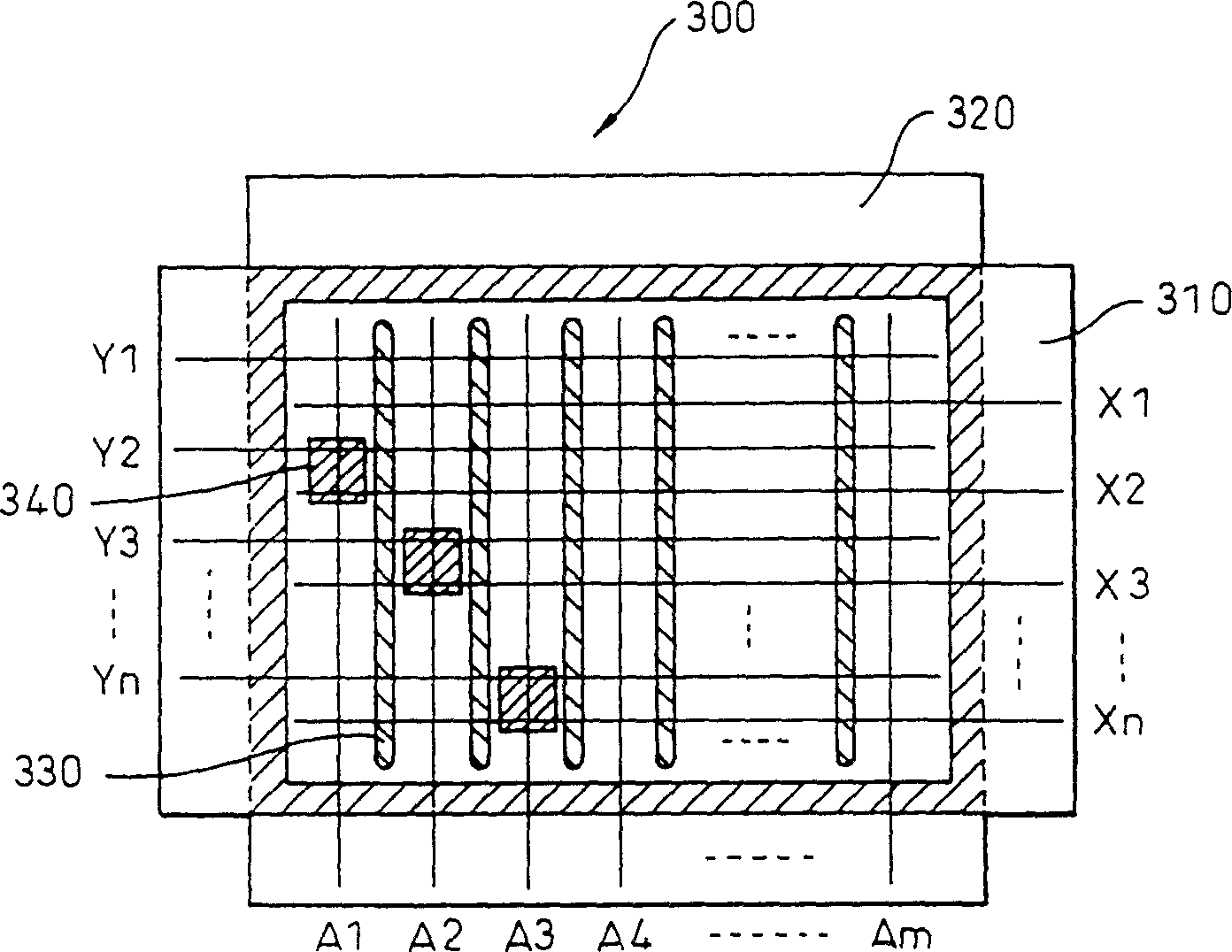

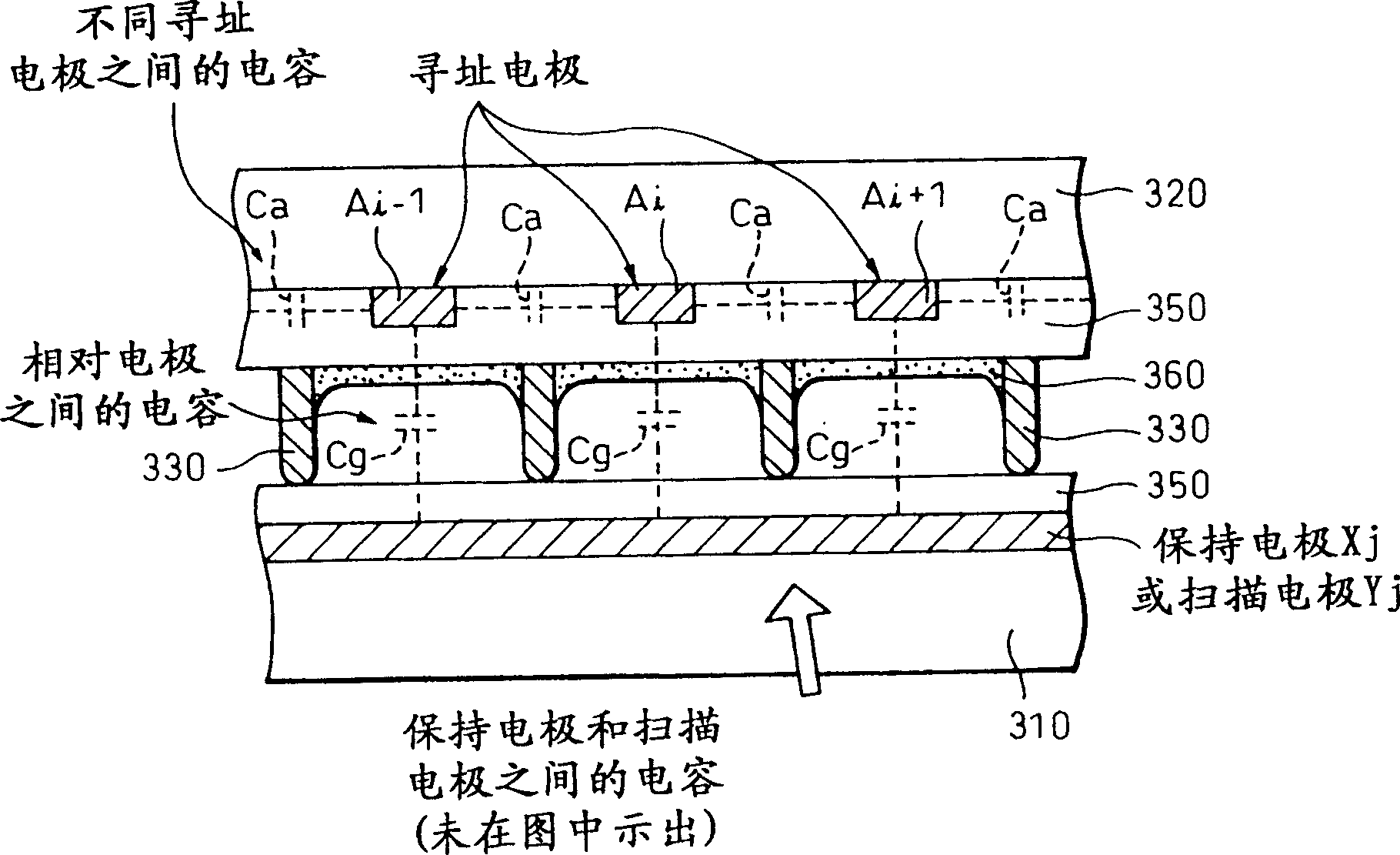

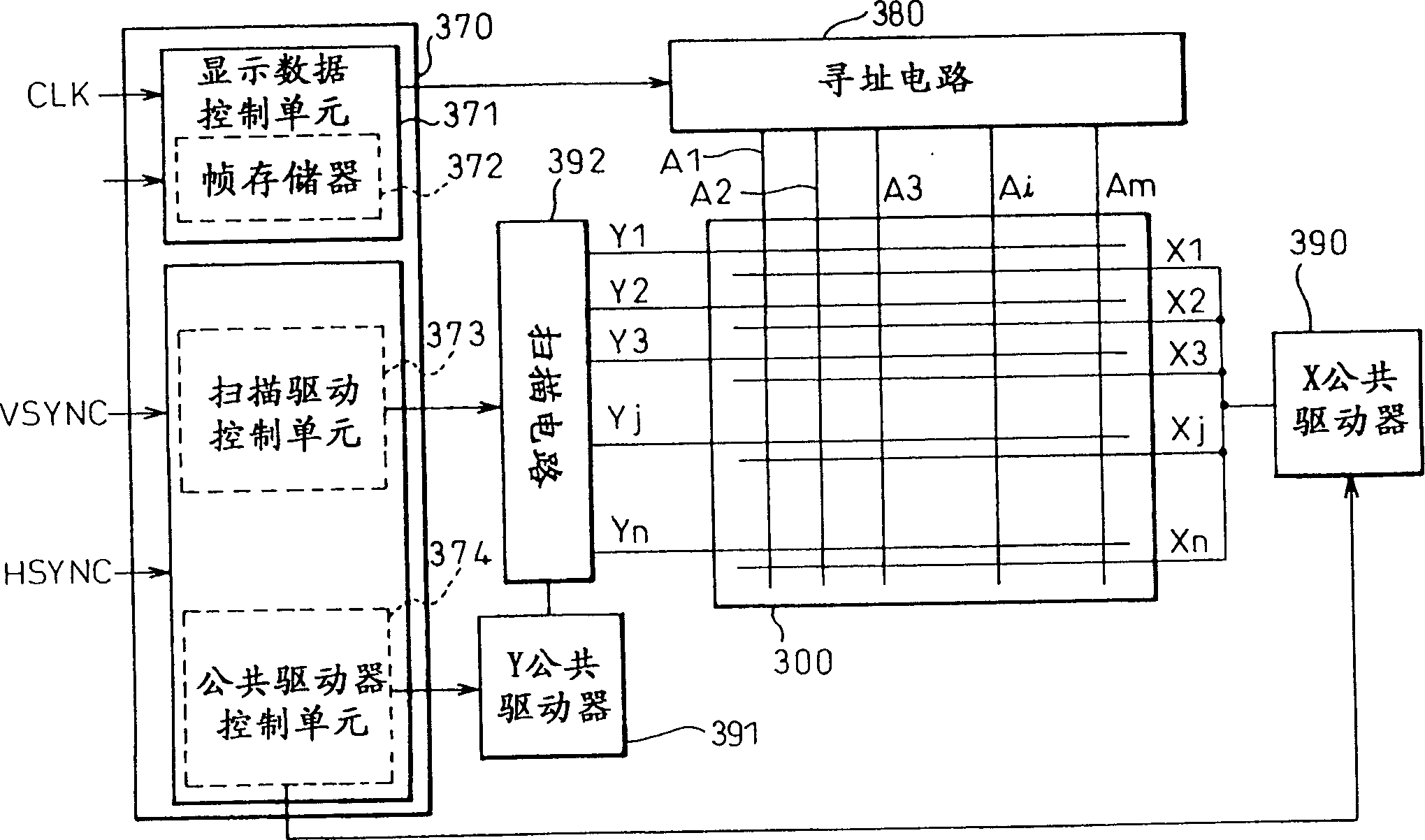

[0093] Refer to the accompanying drawings below ( Figures 11 to 31 ) describes typical preferred embodiments of the present invention. These embodiments are preferably applicable to a drive circuit for driving scan electrodes of a surface discharge AC plasma display panel having three types of electrodes.

[0094] Figure 11 A plan view showing a structure of an assembly mounting a driver IC according to a first embodiment of the present invention. Figure 12 A sectional view showing the structure of an assembly mounting a driver IC according to a first embodiment of the present invention.

[0095] Figure 11 and 12 The first embodiment shown in is an example of applying the driver IC-mounted assembly according to the present invention to the scan electrodes of a surface discharge AC plasma display panel, wherein eight driver IC chips are distributed over two between components that mount the driver IC. However, Figure 11 and 12 A structure of a package 9 mounting a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com