Large-sized dry-process flue gas desulfurizing method with single-tower muiti-bed circulating fluidization

A technology of dry flue gas desulfurization and circulating flow, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve problems such as not being able to meet the fluidization requirements of large-scale flue gas desulfurization reactions, and reduce unit costs , wide adjustment ratio, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

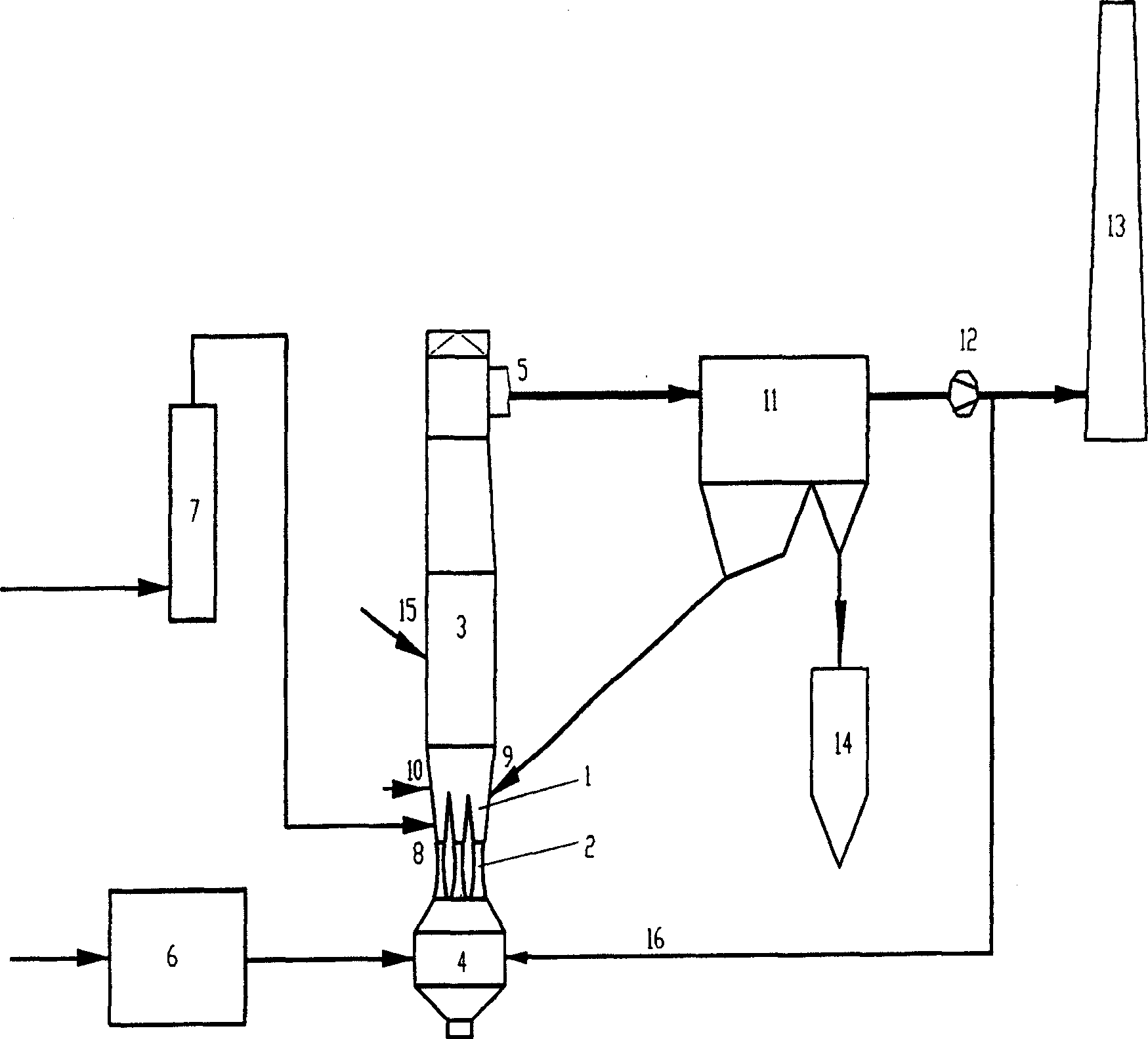

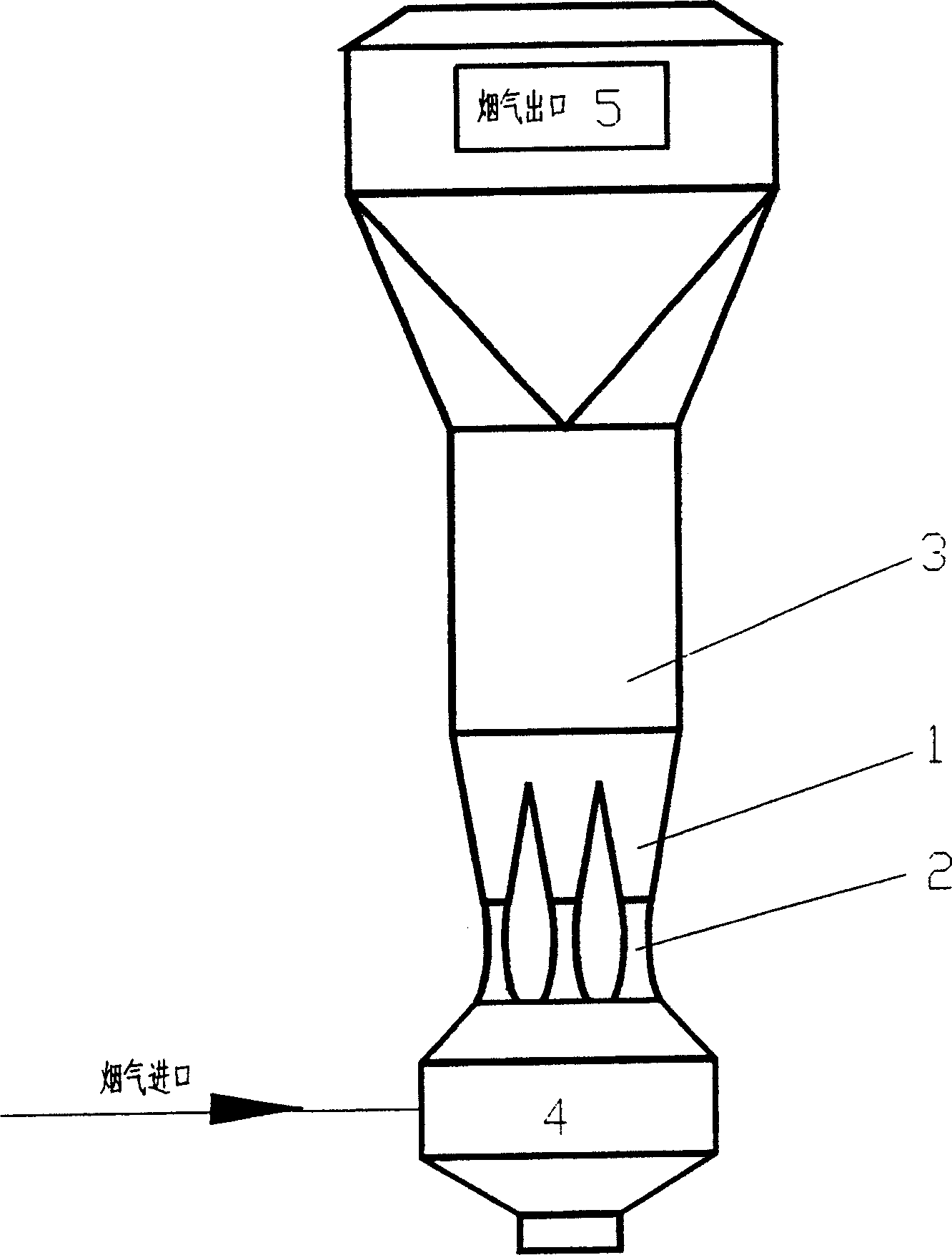

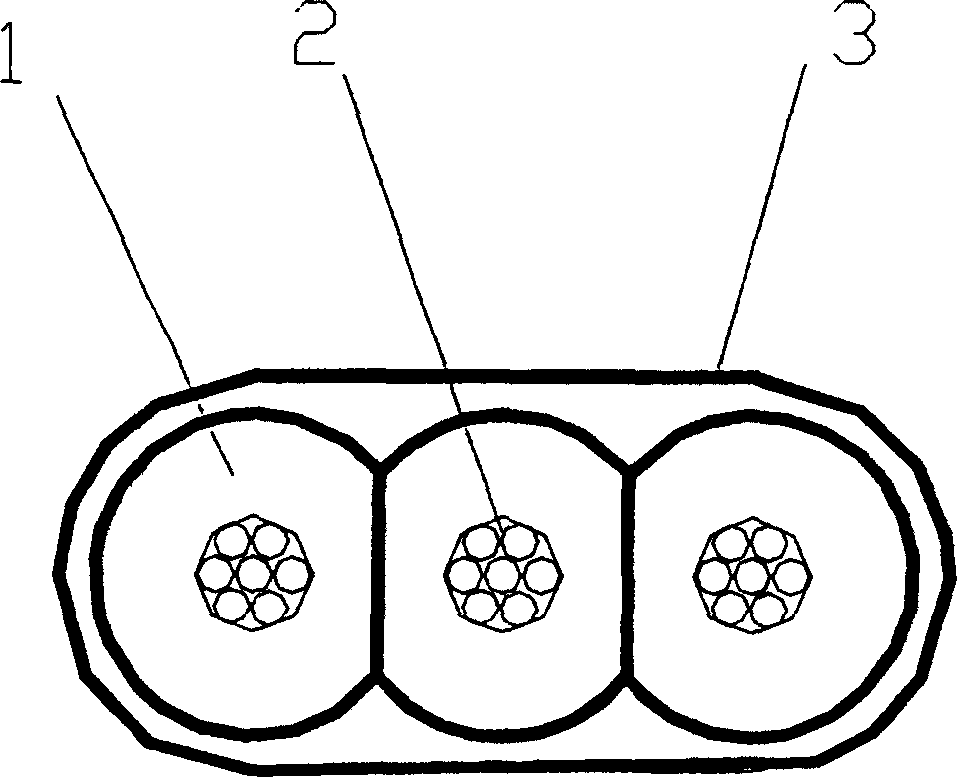

[0029] In the figure: fluidized sub-bed 1, low-resistance flue gas ejection device 2, desulfurization reaction tower body 3, flue gas mixing chamber 4, flue gas deflector 4-1, flue gas outlet of desulfurization tower 5, flue gas preheating Dust removal system 6, digestion system for desulfurization agent preparation 7, desulfurization agent injection inlet 8, return outlet for external recirculation desulfurization agent particles 9, water atomization injection inlet 10, flue gas dust removal system (electrostatic precipitator or bag filter) 11 , main induced draft fan 12, chimney 13, ash bin 14, combined flue gas jet injection port 15, clean flue gas recirculation system 16.

[0030] First, the single-tower design structure of the present invention is characterized in that the bottom of the desulfurization tower is a bifurcated multi-bed structure, and its structural schematic diagram can be seen in the attached figure 2 . The bottom of the desulfurization tower is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com