Fire-resisting plastic insulating conductive band

A flame-retardant plastic, insulating and conductive technology, applied in the direction of insulated cables, insulated conductors, conductors, etc., can solve the problems of broken creases, easy bending, and flexible bending limitations of the connecting part 3, so as to reduce the flame temperature and improve the production efficiency. , the effect of preventing the flame from continuing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

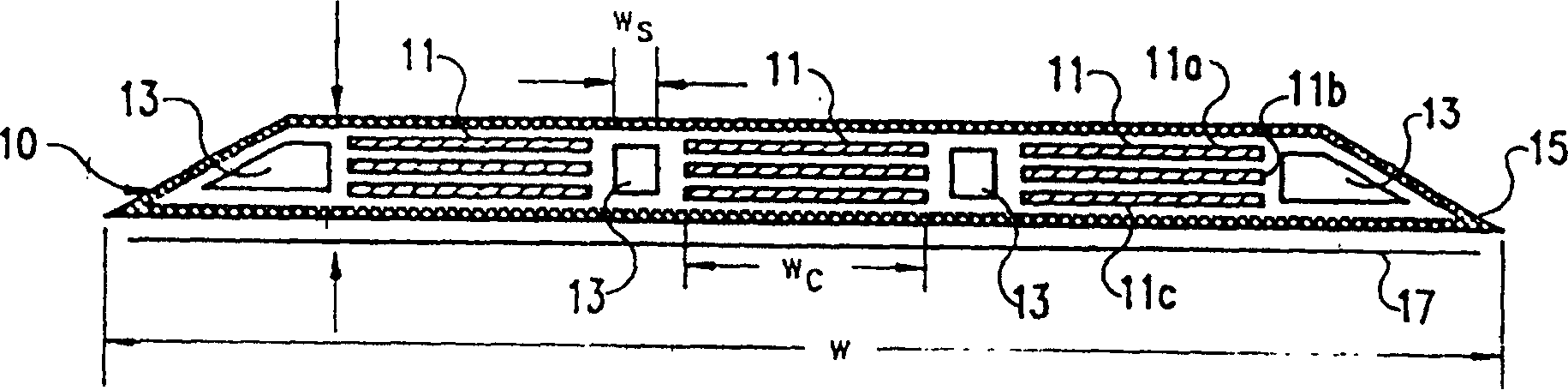

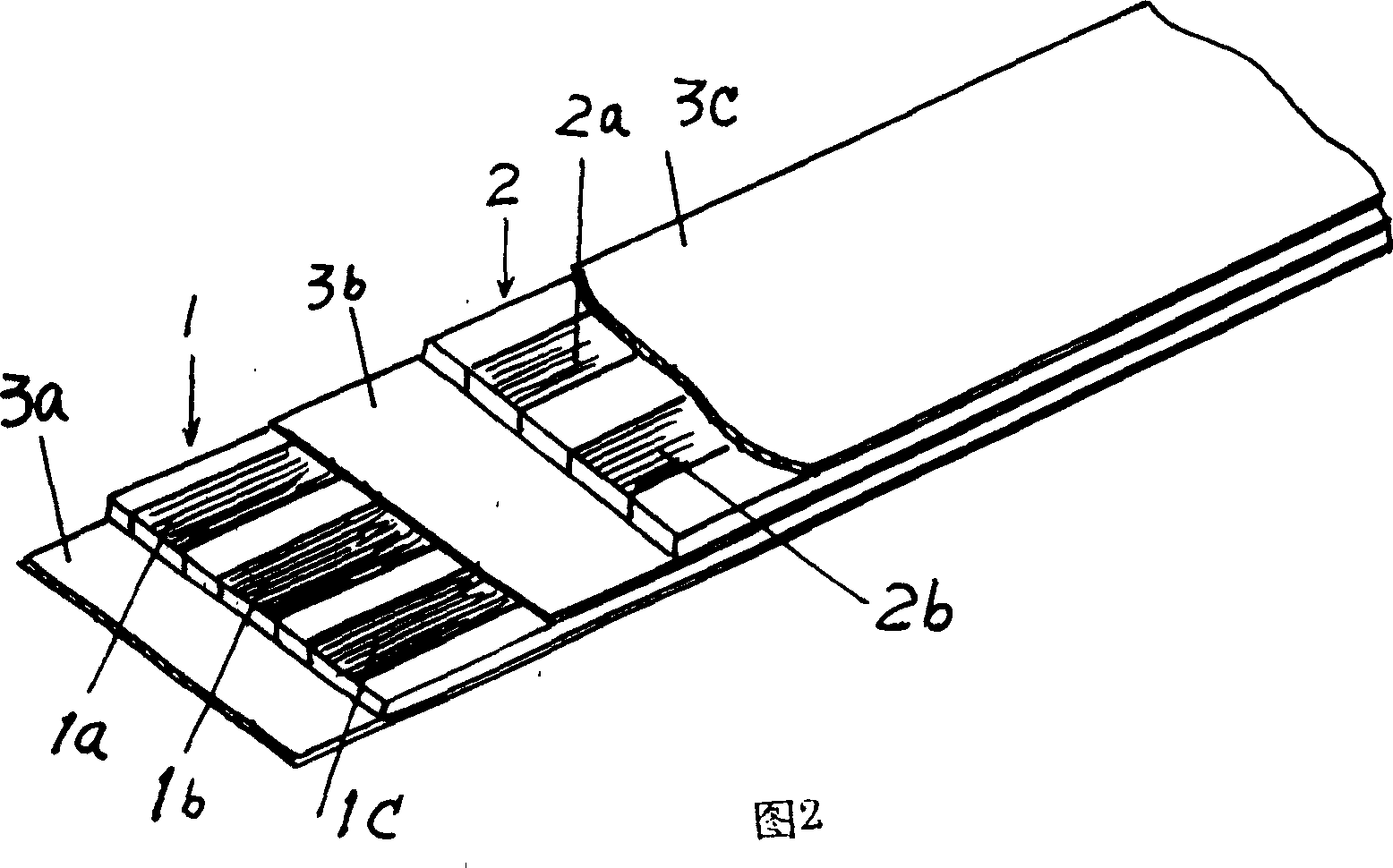

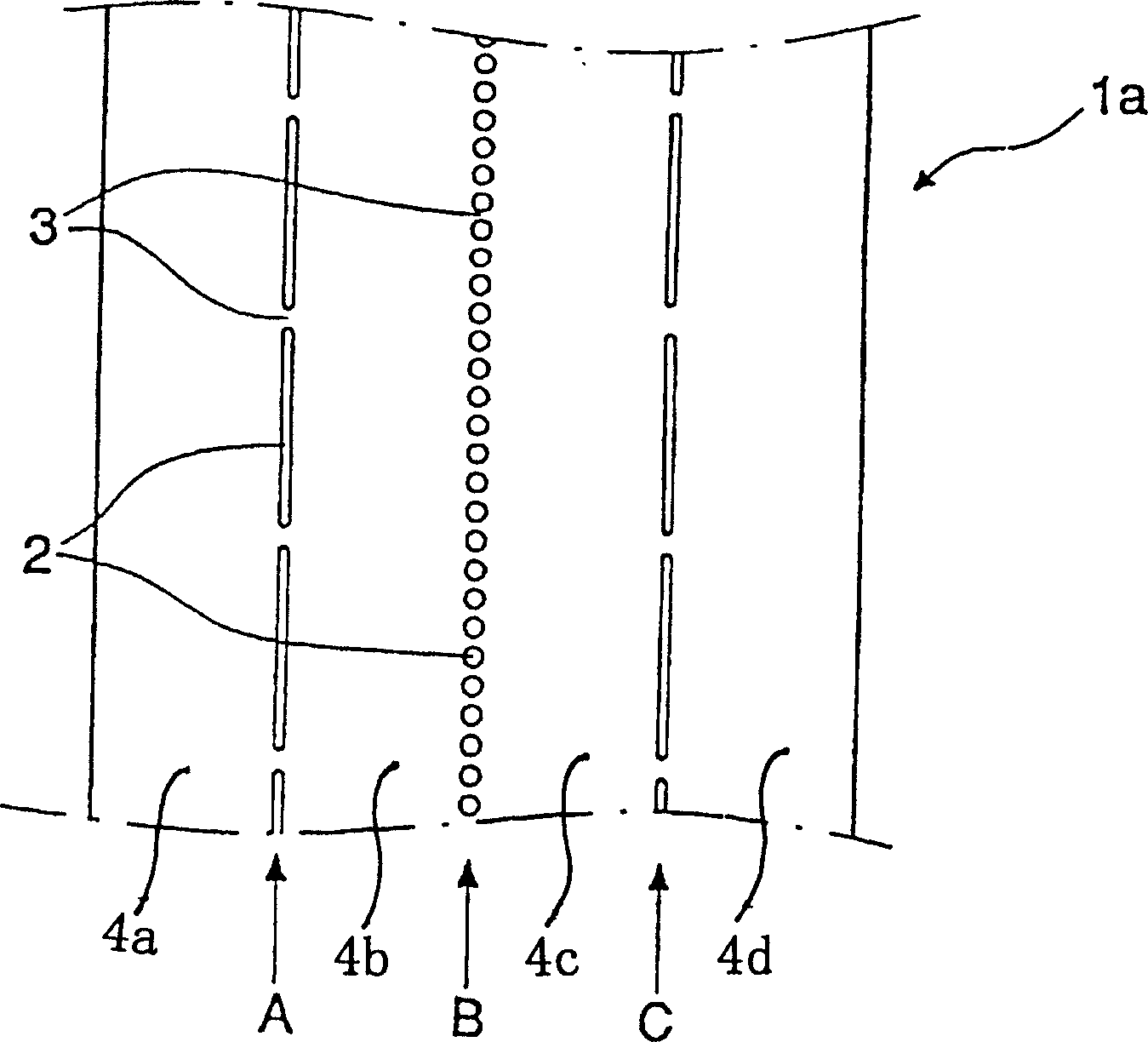

[0023] After overlapping seven copper bars 2 each with a thickness H of 0.5 mm and a width W of 6 mm, they are coated with flame-retardant polyvinyl chloride (PVC) or low-smoke halogen-free polyolefin, thereby forming a flame-retardant plastic of the present invention. Insulated conductive tape.

Embodiment 2

[0025] Only change the thickness H and width W and the number of copper bars 2 to 0.6 mm, 16 mm, and 6 respectively, and the rest are the same as in Embodiment 1.

Embodiment 3

[0027] Only change the thickness H and width W and the number of copper bars 2 to 0.7 mm, 16 mm, and 5 respectively, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com