Method of eliminating fume for regenerated catalyst

A technology for regenerating catalysts and catalysts, applied in chemical instruments and methods, catalyst regeneration/reactivation, physical/chemical process catalysts, etc., can solve problems affecting gas-solid contact efficiency, etc., achieve easy implementation, and prevent the formation of flow dead zones , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] This example shows that the amount of smoke carried by the regeneration agent can be significantly reduced by adopting the method provided by the present invention.

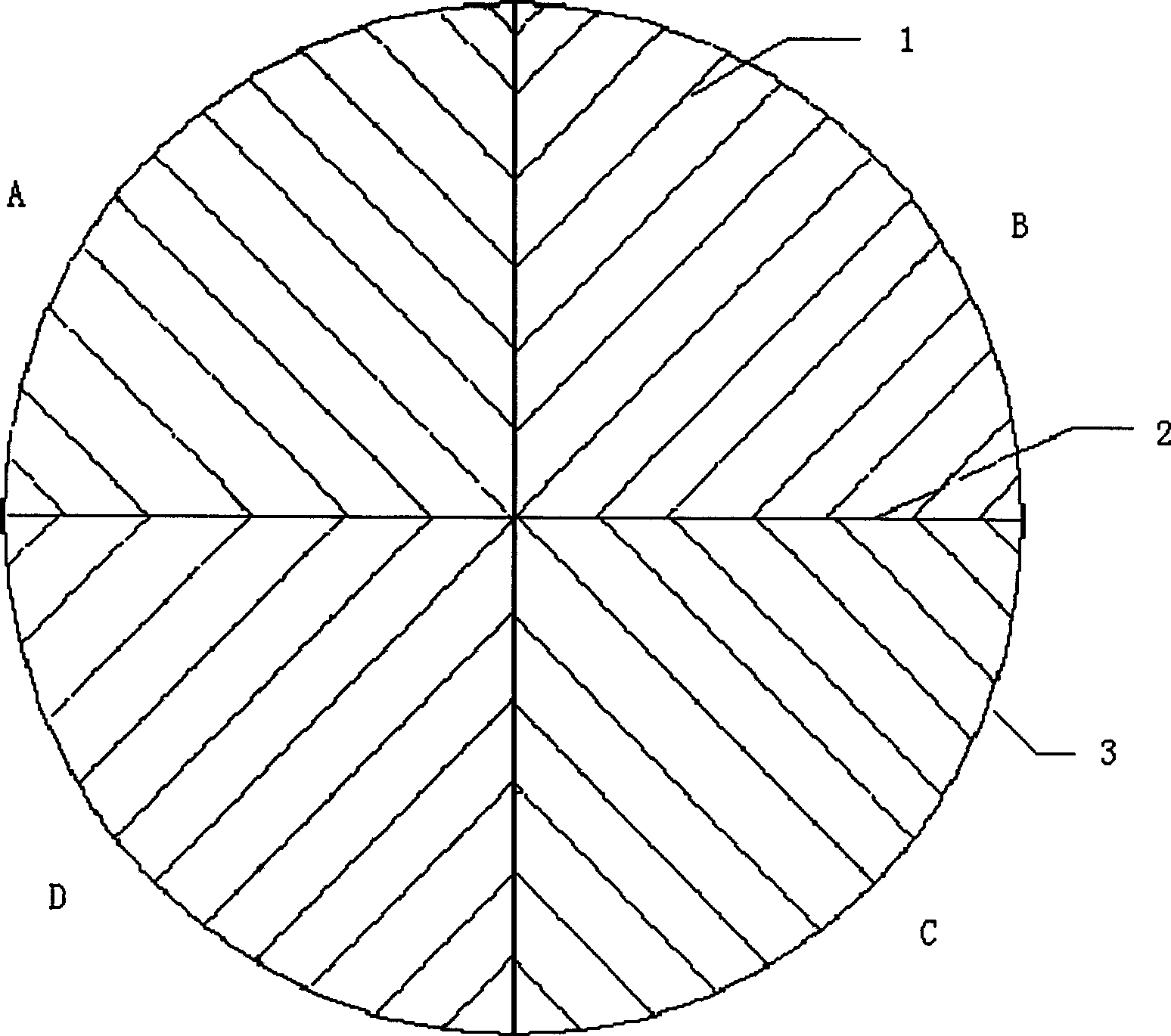

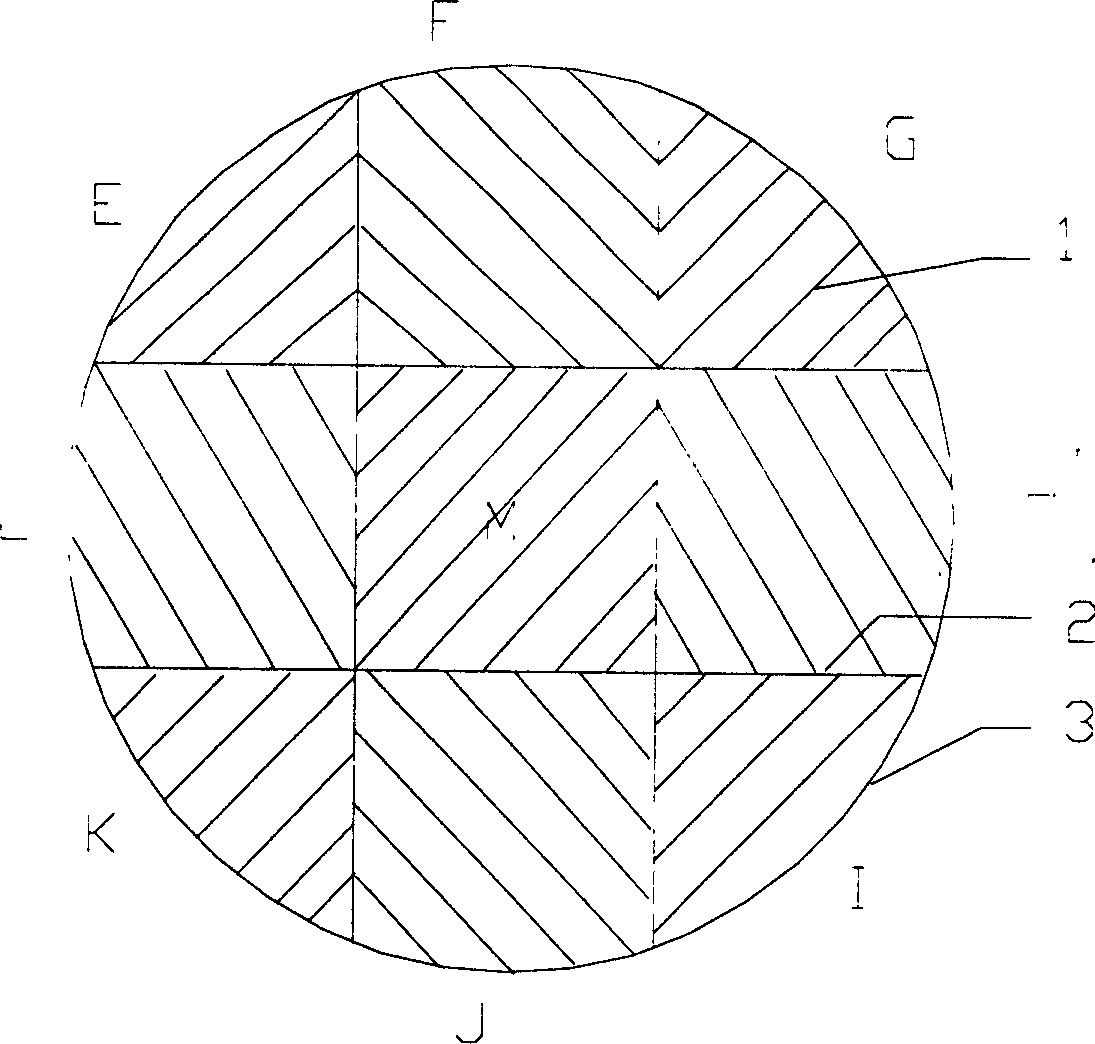

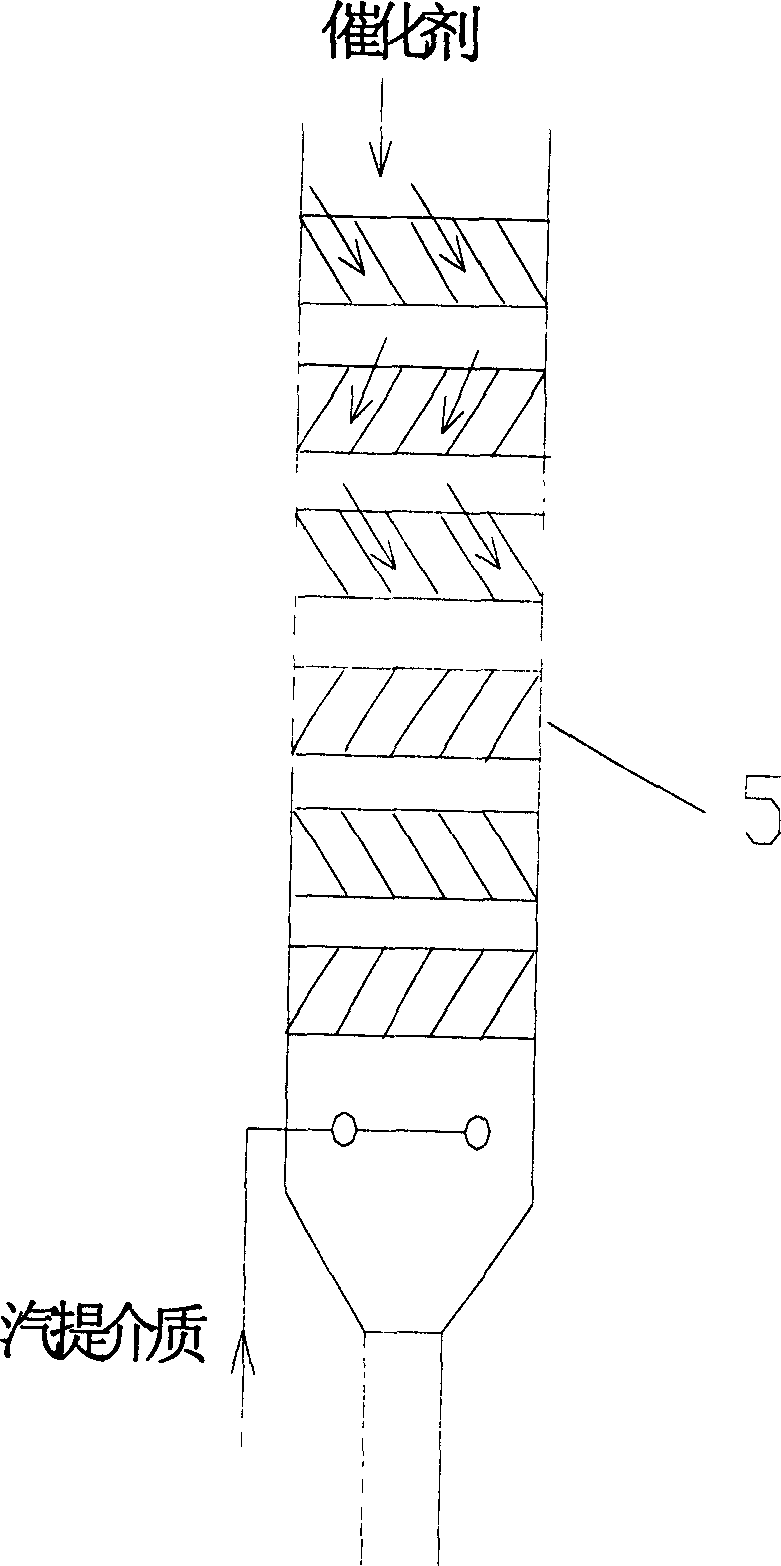

[0037] The medium-sized riser catalytic cracking unit is modified, and a regenerative flue gas stripper is added downstream of the regenerator. Adopt internal member described in the present invention, the structure of internal member is as figure 1 shown. The inner diameter of the regenerative flue gas stripper is 500mm, and four internal components are arranged in the stripper. The height of the inner member is 100mm, and each inner member is divided into 4 areas. The angle between the baffle piece and the horizontal direction in each area is 22.5°, and each inner member is rotated horizontally by 45°C along the axial direction from top to bottom. The interval between every two layers of internal components is 50mm.

[0038] The main properties of the raw oil used in the test are shown in Table 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com