Acid tar oil treating method

A treatment method and technology for acid tar, applied in the direction of refining tar by chemical method, etc., can solve the problems of high labor intensity, excessive volatile components, difficult to handle, etc., to solve technical problems, eliminate serious harm, and have positive social effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

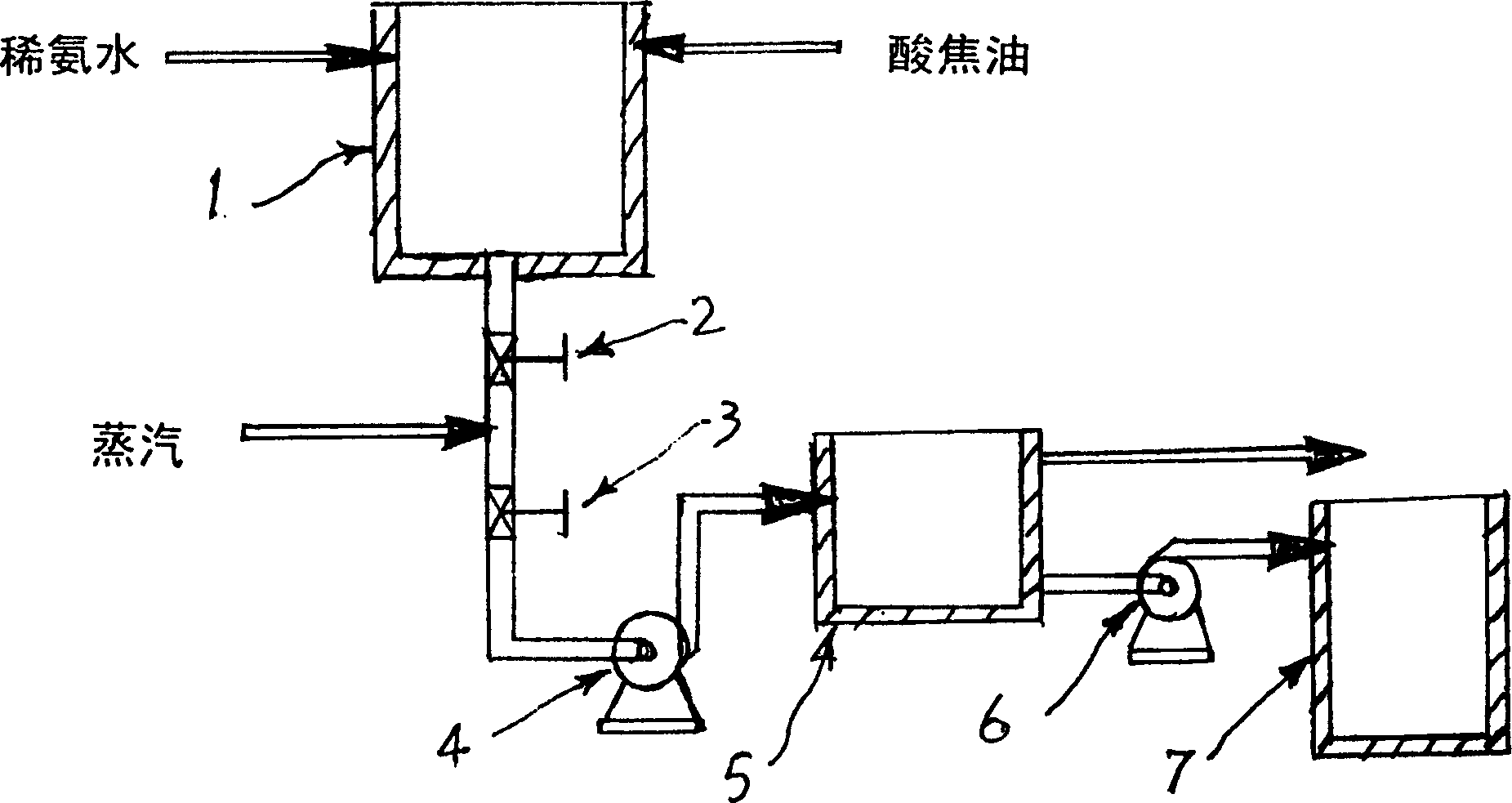

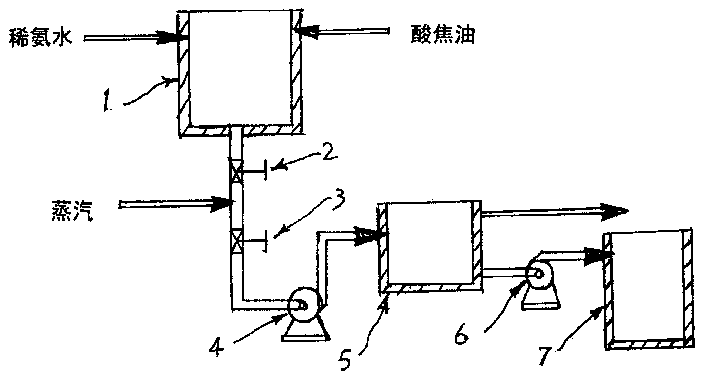

[0023]The coking plant adopts the semi-direct method to recover the nitrogen from the coal gas to produce ammonium sulfate, and put the sulphuric acid tar and dilute ammonia water in the neutralization reaction tank 1. The added amount of the sulphuric acid tar and the diluted ammonia is mixed according to the reaction neutralization. The pH value of the solution is controlled at 6.5. After sulphuric acid tar and dilute ammonia are added to the reaction tank, open the control valve 2 and close the control valve 3, and pass into the neutralization reaction tank through a pipe connection located on the bottom of the reaction tank and also serving as an output pipe connection for the neutralization reaction mixture solution. , The liquid in the reaction tank is heated and maintained at about 80°C to dissolve the sulphuric acid tar in the dilute ammonia, and the sulfuric acid contained in the sulphuric acid tar is neutralized with the dilute ammonia. The reaction time is not less than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com