Apparatus for grinding chinese herb medicines into super-fine powder using chillness

A technology of ultra-fine pulverization and traditional Chinese medicine, which is applied in the direction of making medicines into special physical or ingestible devices, grain processing, etc. It can solve the problems of materials that cannot be pulverized, high cost, and easy oxidation, and achieve high pulverization capacity and energy saving. The effect of fine particles of energy and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

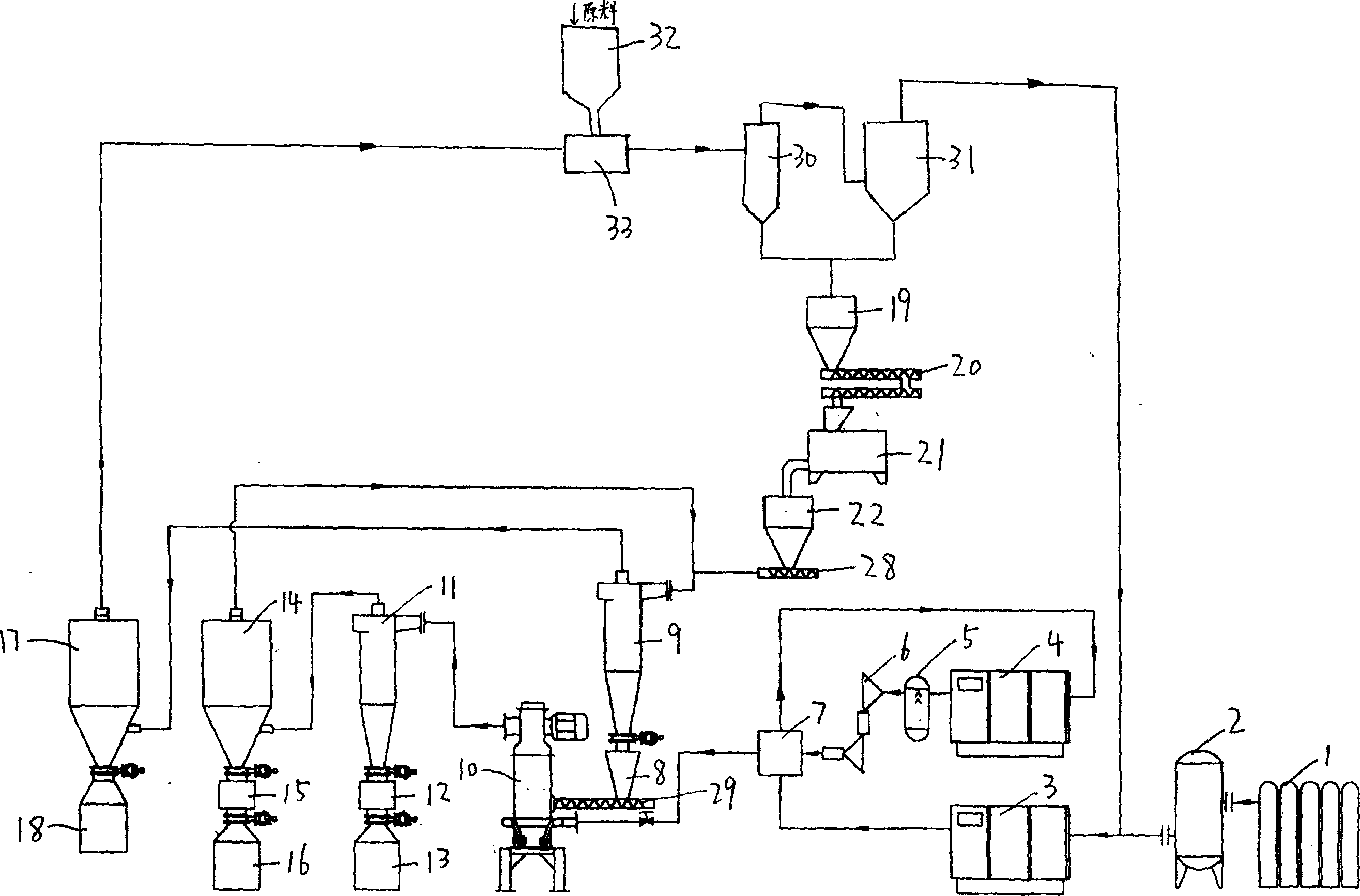

[0014] Example: see figure 1 , a cryogenic traditional Chinese medicine ultrafine pulverization device, including a refrigeration exchange system, a coarse pulverization system, and a low-temperature airflow pulverization system, the arrow drawn on the figure is the flow direction of the cold airflow, and the whole device is closed;

[0015] The refrigeration exchange system mainly includes a gas source 1, a gas storage tank 2, a first gas compressor 3, a second gas compressor 4, a refrigerator 6, and a heat exchanger 7; The gas outlet of the gas storage tank 2 is connected to the first gas compressor 3, the first gas compressor 3 is connected to the heat exchanger 7, one end of the second gas compressor 4 is connected to the refrigerator 6 through the degreaser 5, and the refrigerator 6 is connected to the heat exchanger 7. The heat exchanger 7 is connected to the other end of the second gas compressor 4, and the heat-exchanged cold air flow forms a closed loop between the ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com