Nanometer antibacterial plastic pipe and preparation process thereof

A technology of antibacterial plastics and plastic pipes, applied in the field of building materials, can solve problems such as secondary pollution of water quality, achieve the effects of maintaining cleanliness, reducing consumption, and reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

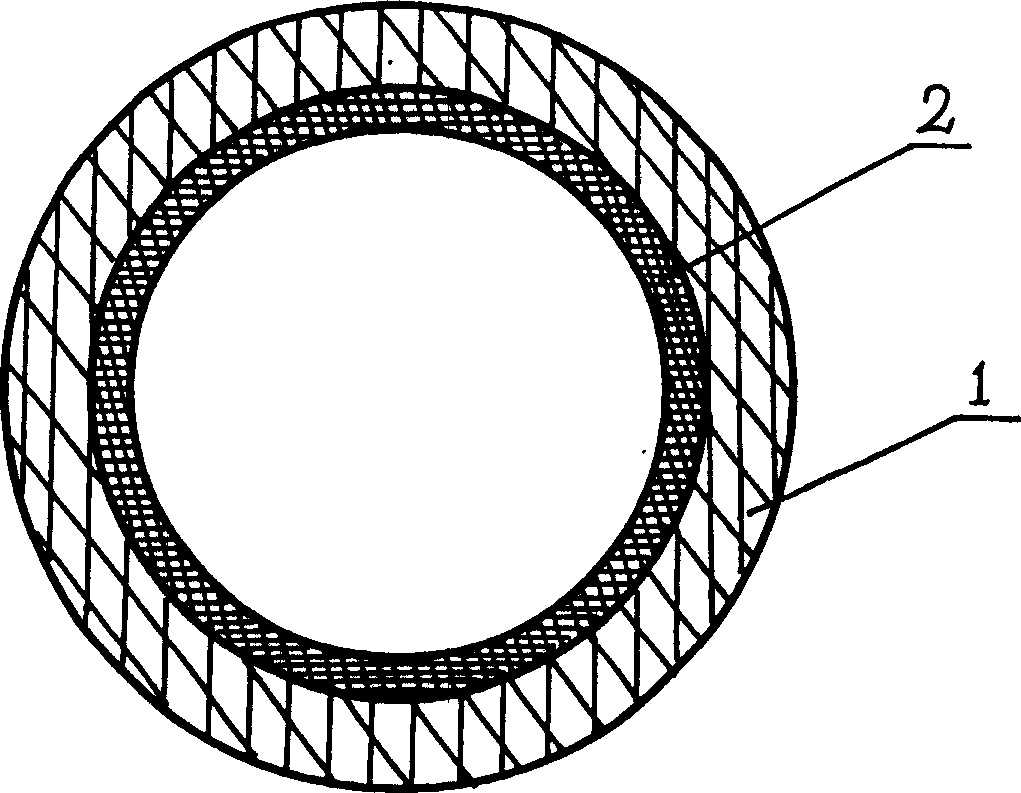

[0031] Embodiment 1: as figure 1 Shown, the present invention comprises plastic outer layer 1 and plastic inner layer 2, and plastic outer layer 1 is made of common thermoplastics, and what plastic inner layer 2 adopted is to be made of 5 weight parts nano-scale antibacterial masterbatch and 95 weight parts common thermoplastics The antibacterial plastic of making, wherein nanoscale antibacterial masterbatch is made by the raw material of following weight ratio (consumption is weight part):

[0032] Silver-loaded zirconium phosphate inorganic antibacterial agent 20 parts phenolic antioxidant 0.35 part

[0033] 0.3 parts of dispersant, 0.4 parts of salicylate absorbent

[0034] 0.4 parts of titanate coupling agent 100 parts of thermoplastic base material

[0035] The above-mentioned raw materials are fully mixed by a mixer according to the proportion. After the materials are mixed evenly, they are added to a twin-screw extrusion granulation unit for melting. The processing te...

Embodiment 2

[0038] Embodiment 2: as figure 1 Shown, the present invention comprises plastic outer layer 1 and plastic inner layer 2, and plastic outer layer 1 is made of PP-R plastics, and what plastic inner layer 2 adopted is by 10 weight parts nano-scale antibacterial masterbatch and 90 weight parts PP- The antibacterial plastic that R plastic is made, wherein nanoscale antibacterial masterbatch is made by the raw material of following weight ratio (consumption is weight part):

[0039] Silver-loaded zirconium phosphate inorganic antibacterial agent 25 parts phenolic antioxidant 0.5 part

[0040] 0.4 part of dispersant, 0.5 part of salicylate absorbent

[0041] 0.5 parts of titanate coupling agent 100 parts of PP-R plastic base material

[0042] The above-mentioned raw materials are fully mixed by a mixer according to the proportion. After the materials are mixed evenly, they are added to a twin-screw extrusion granulation unit for melting. The processing temperature is 160 ° C ~ 220 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com