Small moleoule rare-earth atom containing composite molecular sieve and preparing method thereof

A composite molecular sieve, molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the gel mentioned in the step (a) is to fully mix the required substances in a certain order to obtain a homogeneous colloidal mixture. The mol ratio of each material in the gained gel is generally:

[0035] 0.8~2.0M 2 O / 1.0~5.0R / 0.01~1.0Al 2 o 3 / 10SiO 2 / 0.1~2.0NX / 50~600H 2 O / 0.01~2.0Re 2 o 3 , preferably:

[0036] 1.0~1.5M 2 O / 2.0~4.0R / 0.05~0.5Al 2 o 3 / 10SiO 2 / 0.2~1.0NX / 100~500H 2 O / 0.05~0.5Re 2 o 3 , more preferably:

[0037] 1.1~1.4M 2 O / 2.5~3.5R / 0.1~0.2Al 2 o 3 / 10SiO 2 / 0.2~0.5NX / 300~400H 2 O / 0.05~0.2Re 2 o 3 , where R is an organic template, M is a monovalent alkali metal ion, NX is a halide, and Re is a rare earth element.

[0038] The crystallization mentioned in the step (b) is carried out in a high-pressure reactor with autogenous pressure, and the crystallization temperature is 120 to 200°C, preferably 150 to 180°C, more preferably 160 to 170°C; the crystallization time is 10 ~240 hours, preferably 24~96 ho...

Embodiment 1

[0052] Using the gel with the same composition as that described in Comparative Example 2, under the condition of a stirring speed of 200 rpm, after the same crystallization and post-treatment process as in Comparative Example 2, the sample number E-1 was obtained.

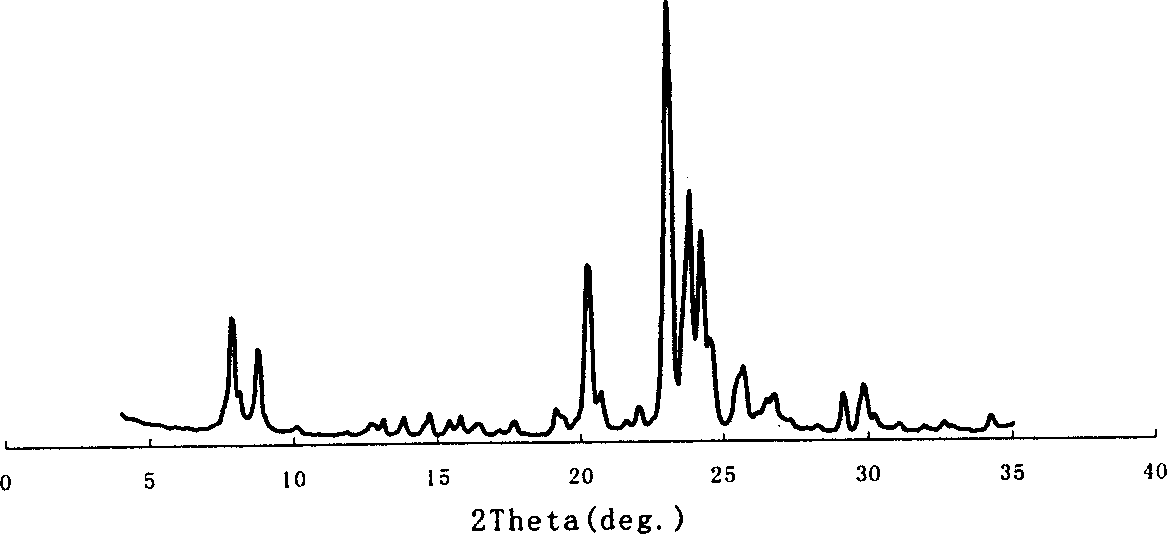

[0053] Characterization: E-1 SiO 2 / Al 2 o 3 58, SiO 2 / La 2 o 3 for 92. The XRD result of sample E-1 has the characteristics of Table 1 and Table 2, see Figure 5 , see SEM Figure 6 . Depend on Figure 5 It can be seen that the product has two structural molecular sieve characteristics of MFI and TON, and the ratio of the content of molecular sieves with MFI structure and TON structure is 0.6; SEM results show that the product is needle-like crystals with an average length of about 0.4 microns.

Embodiment 2

[0058] The preparation steps of molecular sieve mainly include:

[0059] (a) The preparation process of the gel is: the same as in Example 1, except adding 20.50 grams of 82% KOH, 25.3 grams of 1,8-octanediamine, 10 grams of Al 2 (SO 4 ) 3 .18H 2 O replaces 4 g of AlCl 3 , 5.8 grams of KF, 17.4 grams of La (NO 3 ) 3 ·6H 2 O and 400 grams of water were mixed together and vigorously stirred for 20 minutes to obtain a homogeneous gel-like mixture. The molar composition of the obtained gel was:

[0060] 1.5K 2 O / 2.01R / 0.08Al 2 o 3 / 10SiO 2 / 1.0KF / 0.20La 2 o 3 / 300H 2 o

[0061] R = 1,8-octanediamine

[0062] (b) crystallization process: same as embodiment 1.

[0063] (c) Post-treatment process: Same as in Example 1, the obtained sample number is E-2.

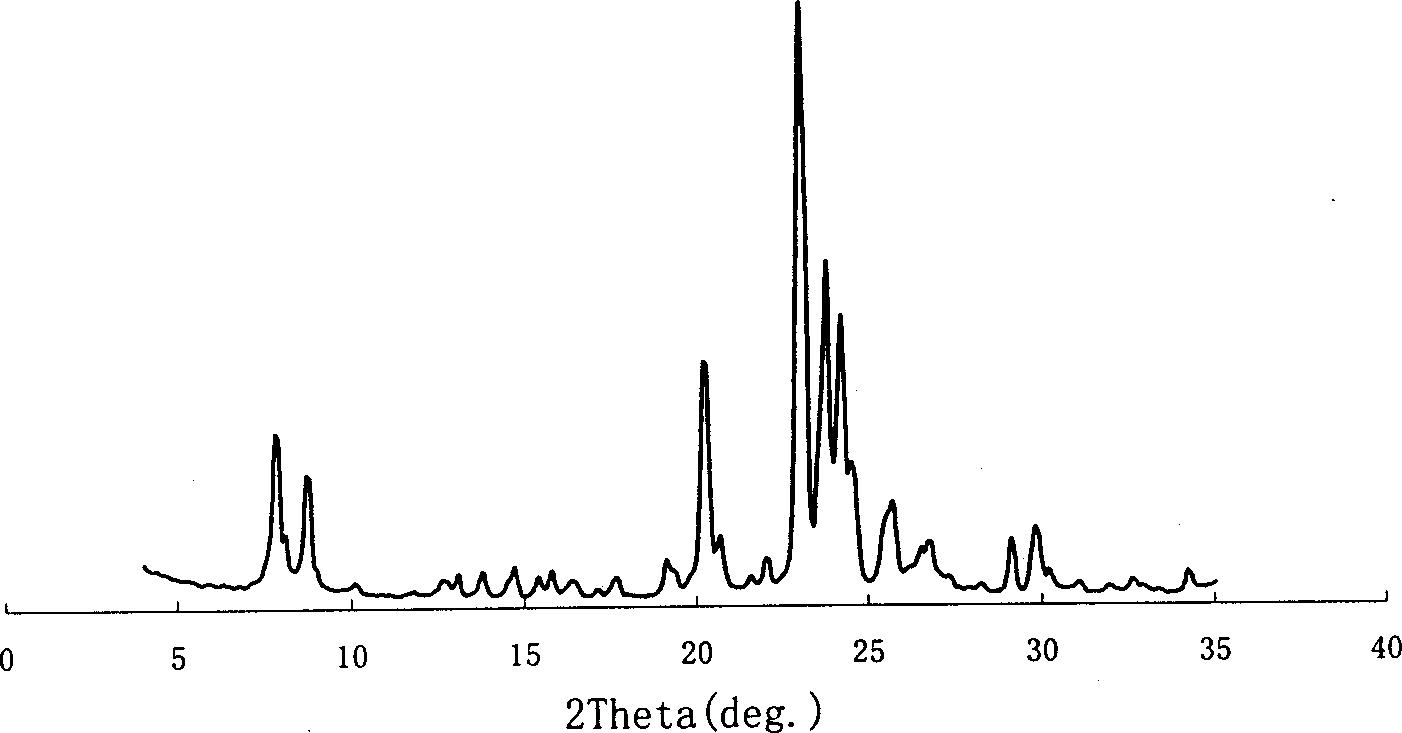

[0064] (d) Characterization: SiO of E-2 2 / Al 2 o 3 104, SiO 2 / La 2 o3 for 44. The XRD result of sample has table 1 and table 2 characteristic, see Figure 9 , see SEM Figure 10 . Depend on Figure 9 It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com