Process for crystallization of reverse transcriptase inhibitor using anti-solvent

A technology of anti-solvent and process, which is applied in the field of crystallization process of reverse transcriptase inhibitors using anti-solvent, which can solve the problems of high viscosity, unevenness, difficulty in mixing and handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

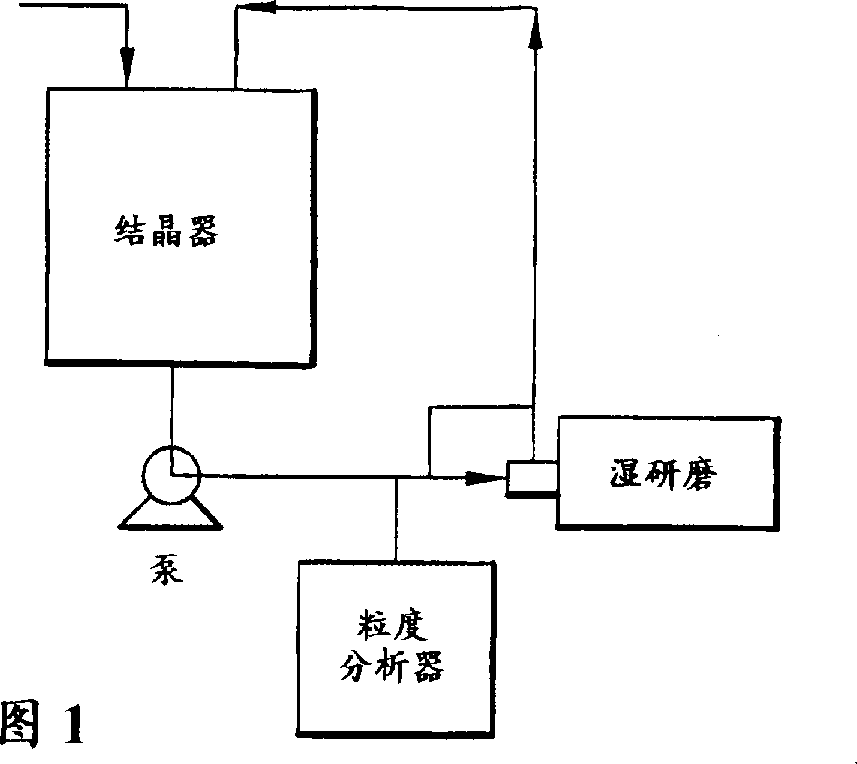

[0059] Controlled anti-solvent addition crystallization process

[0060] 400 grams of DMP-266 starting material were dissolved in 2.400 liters of ethanol. See Figure 1. The solution was filtered to remove foreign matter. 2.088 liters of deionized (DI) water were added to the solution over a period of 30-60 minutes. To this solution was added 20 grams of DMP-266 seed crystals. The seed layer was allowed to age for 1 hour. The slurry is preferably mixed with an Intermig mixer. If necessary (due to the presence of overgrown crystals or a viscous slurry), the slurry can be wet milled for 15-60 seconds. 1.512 liters of DI water were added to the slurry over a period of 4-6 hours. If necessary (due to the presence of excessively long crystals or a thick slurry), the slurry can be wet milled for 15 to about 60 seconds during the addition. The slurry was allowed to age for 1-3 hours and then cooled to 10°C over 3 hours. The slurry was aged for 2-16 hours until the product conc...

example 2

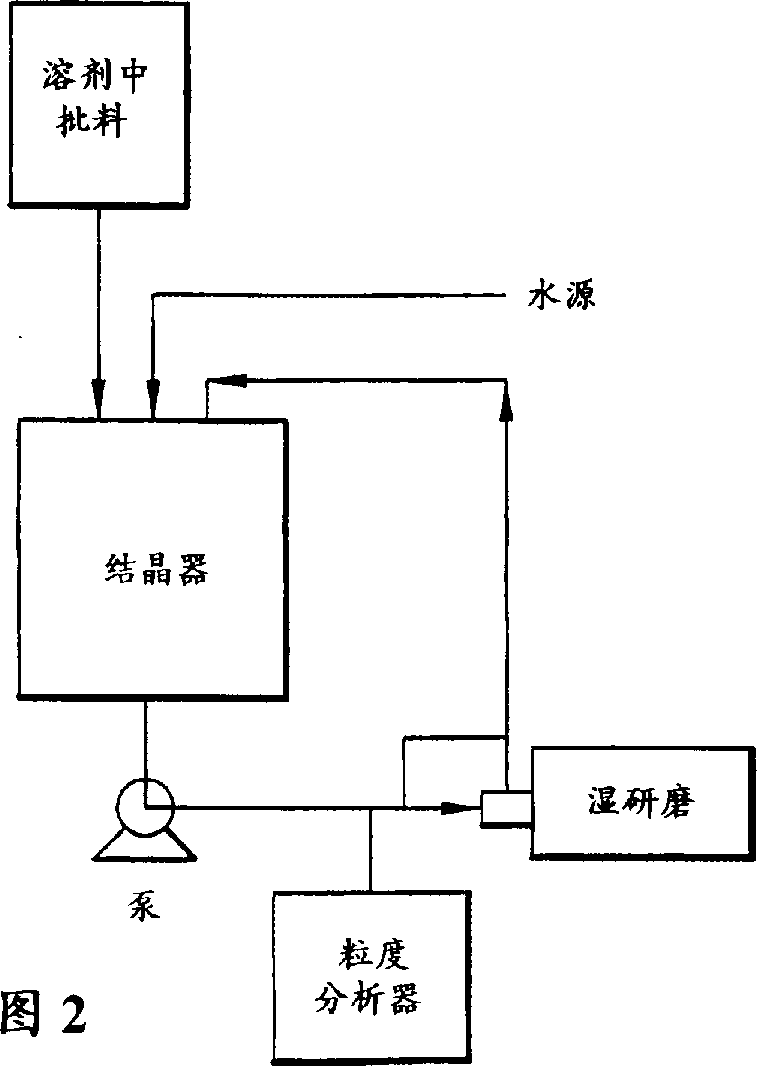

[0062] Semi-continuous tailings crystallization process

[0063] 400 grams of DMP-266 starting material were dissolved in 2.400 liters of ethanol. See Figure 2. Mix 20 grams of DMP-266 with 0.3 liter of 40% (volume ratio) ethanol aqueous solution to prepare tailing slurry. The dissolved batch and 3.6 liters of DI water were simultaneously added to the above tailings slurry at a constant rate over a period of 6 hours to maintain a constant solvent composition in the crystallizer. It is best to use an Intermig stirrer during crystallization. During this addition, the slurry may be wet milled when the crystal length becomes too long or the slurry becomes too thick. The slurry was aged for 2-16 hours until the product concentration in the supernatant remained constant. The slurry was filtered and a crystalline wet cake was isolated. The wet filter cake was first washed with 1-2 bed volumes of 40% aqueous ethanol solution, and then washed twice with 2 liters of DI water each. ...

example 3-8

[0066] * The sum of solvent and water must be at least 12ml / g. The currently preferred concentration is

[0067] 15ml / g.

[0068] - the method doesn't work.

[0069] ×This method works.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com