Filtering and flow-stabilizing device

A ballast and filter technology, applied in the field of automatic water supply device manufacturing without towers and pools, can solve the problems of long lichen, rust in the water tank, and the structure and technology cannot be removed, so as to achieve less investment and realize the Stability and the effect of preventing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

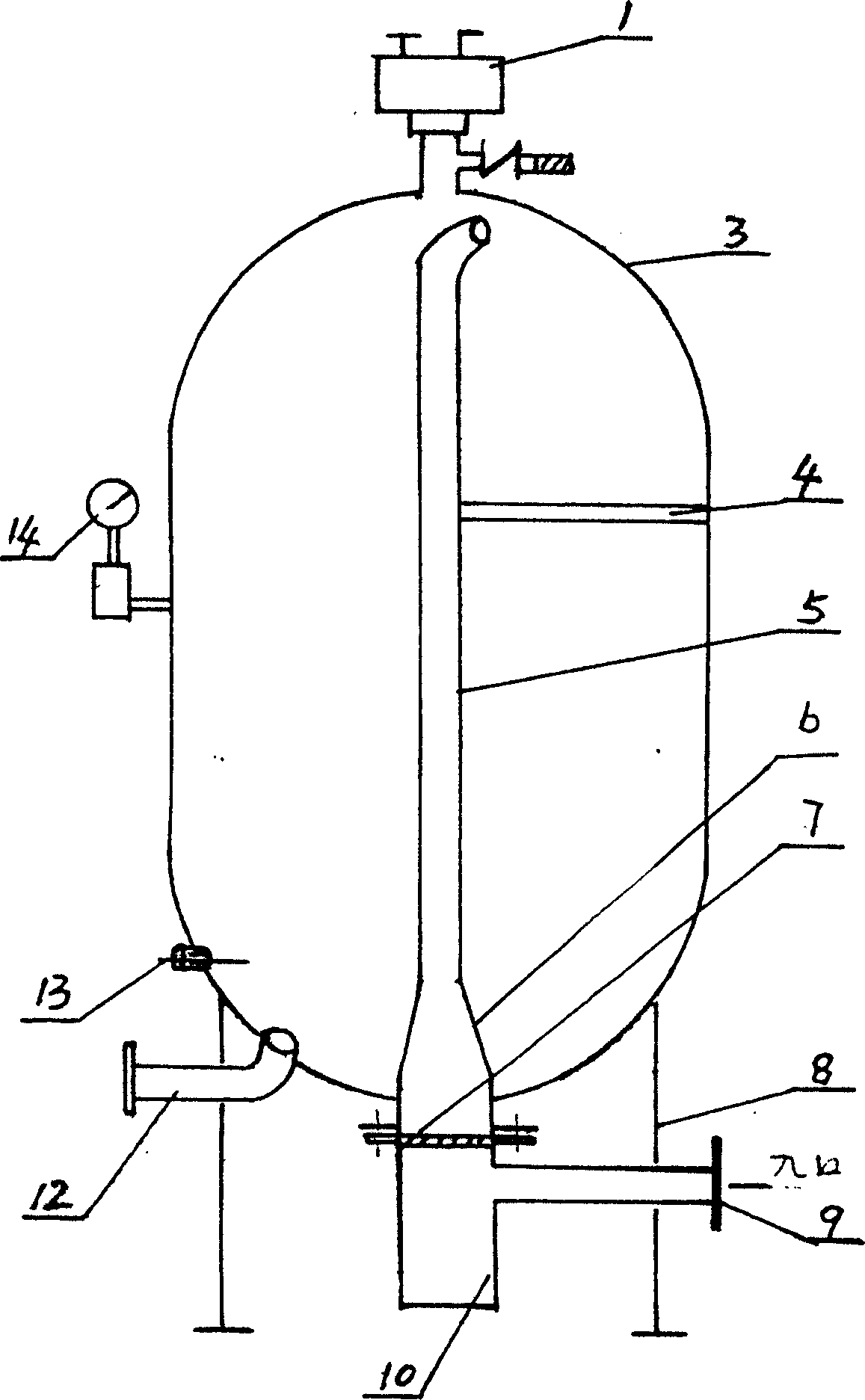

[0009] Embodiment 1: with reference to attached figure 1 . Filter ballast, which includes a controller, the cone reducing tube 6 is located in the ballast body 3, the cone reducing tube 6 communicates with the upper part of the filter body 10, the filter screen 7 is located in the filter body, and the water inlet 9 Connected to the filter body. One end of the guide tube 5 communicates with the tapered reducing tube 6 , and the other port is located in the ballast body 3 , and the guide tube 5 is fixed in the ballast body by the fixing bracket 4 . One end of the water outlet 12 is connected to the bottom of the ballast body, and the other end is connected to one or more water supply pipes in the motor pump water supply assembly. The upper end of the ballast body is provided with an automatic air intake and exhaust valve 1 . The lower part of the ballast body is provided with a water detection electrode 13, and its detection signal is sent to the frequency conversion soft star...

Embodiment 2

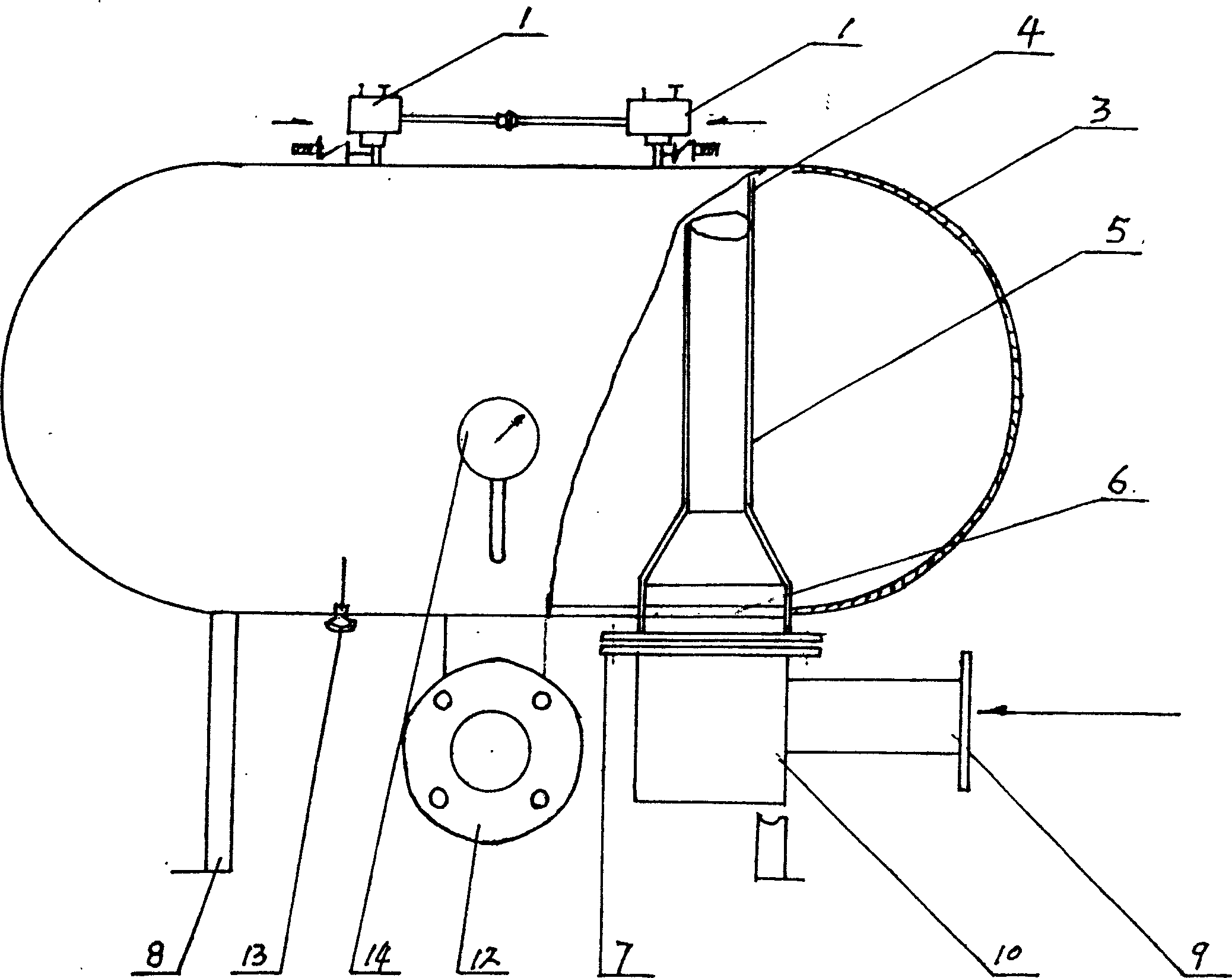

[0010] Embodiment 2: with reference to attached figure 2 . On the basis of Embodiment 1, the ballast body is in a horizontal structure.

Embodiment 3

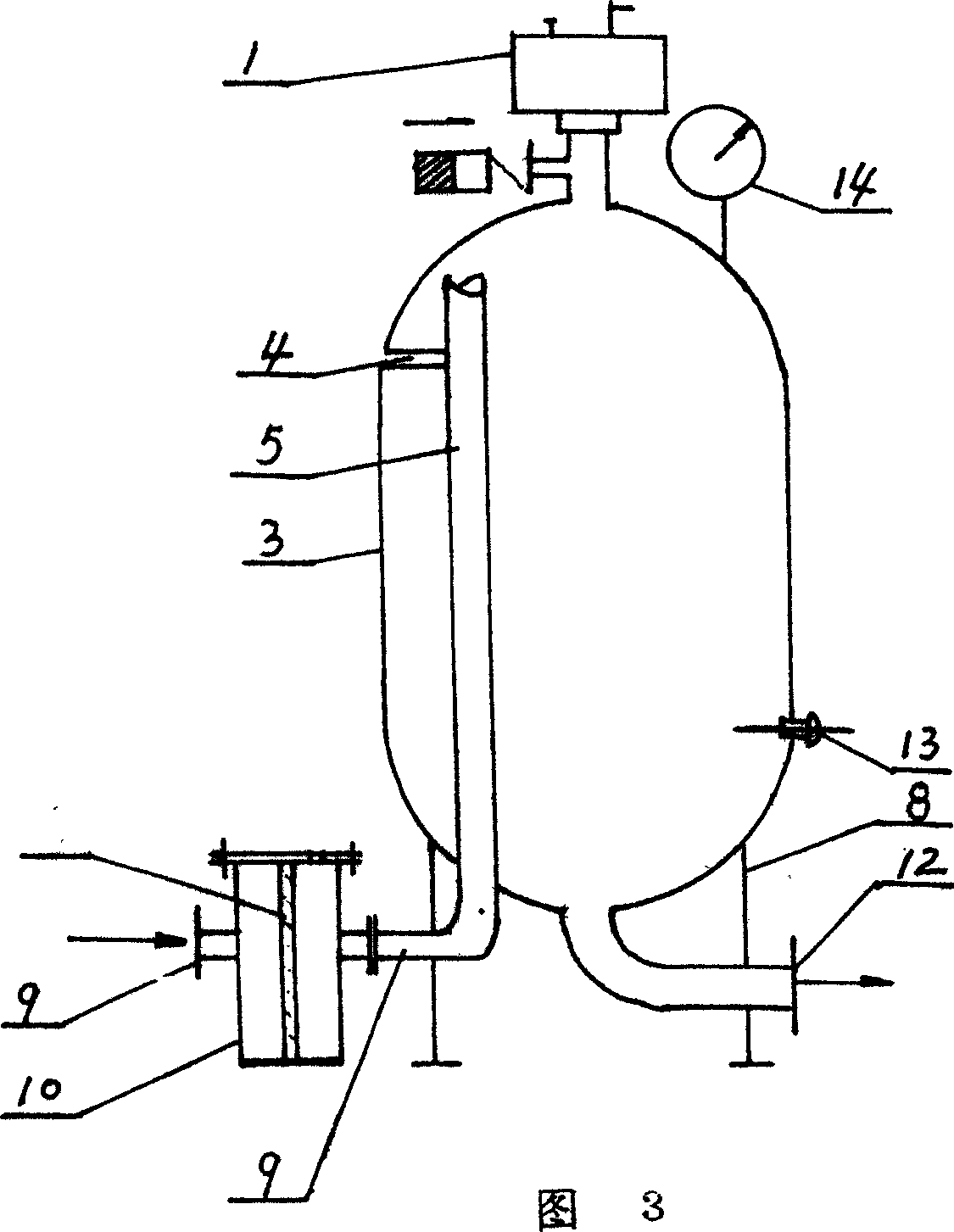

[0011] Embodiment 3: with reference to accompanying drawing 3. On the basis of Embodiment 1, the filter body 10 communicates with the guide pipe 5 through a connecting pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com