Motor

A technology for electric motors and electric vehicles, applied in the field of electric motors, can solve problems such as characteristic degradation, affecting motor noise, vibration, permanent magnet magnetic flux leakage, etc., to achieve the effects of reducing noise, high speed, and reducing torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

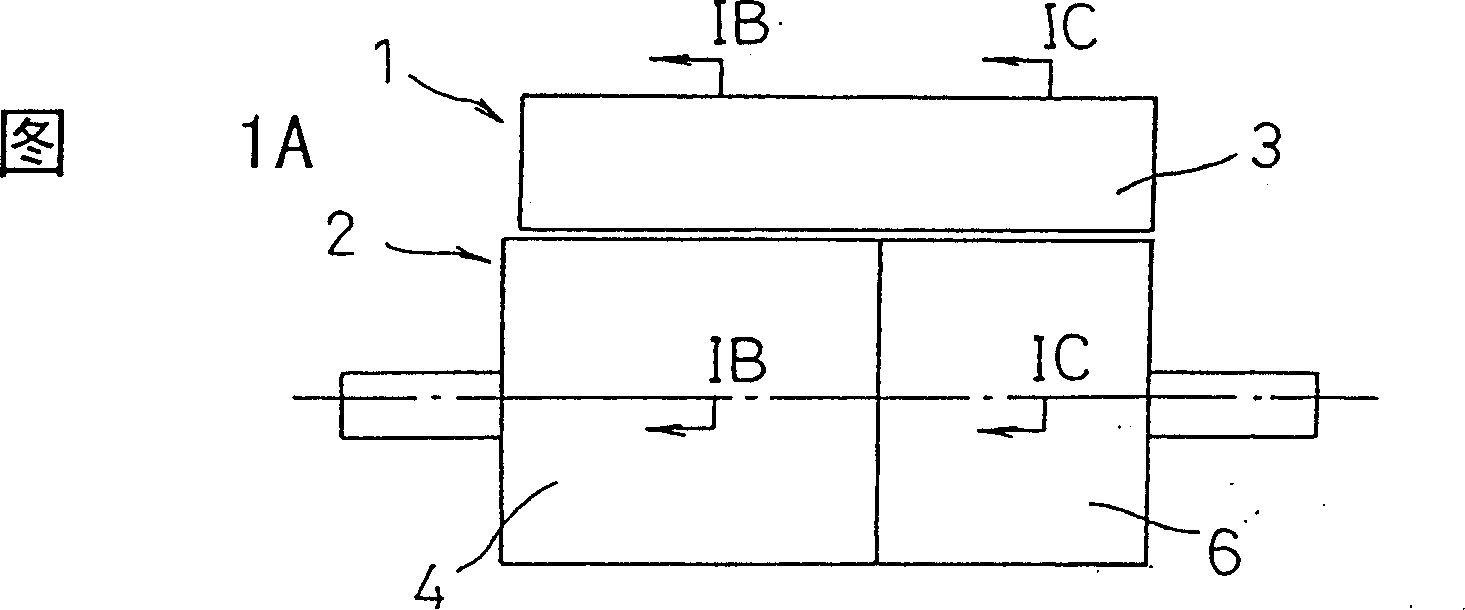

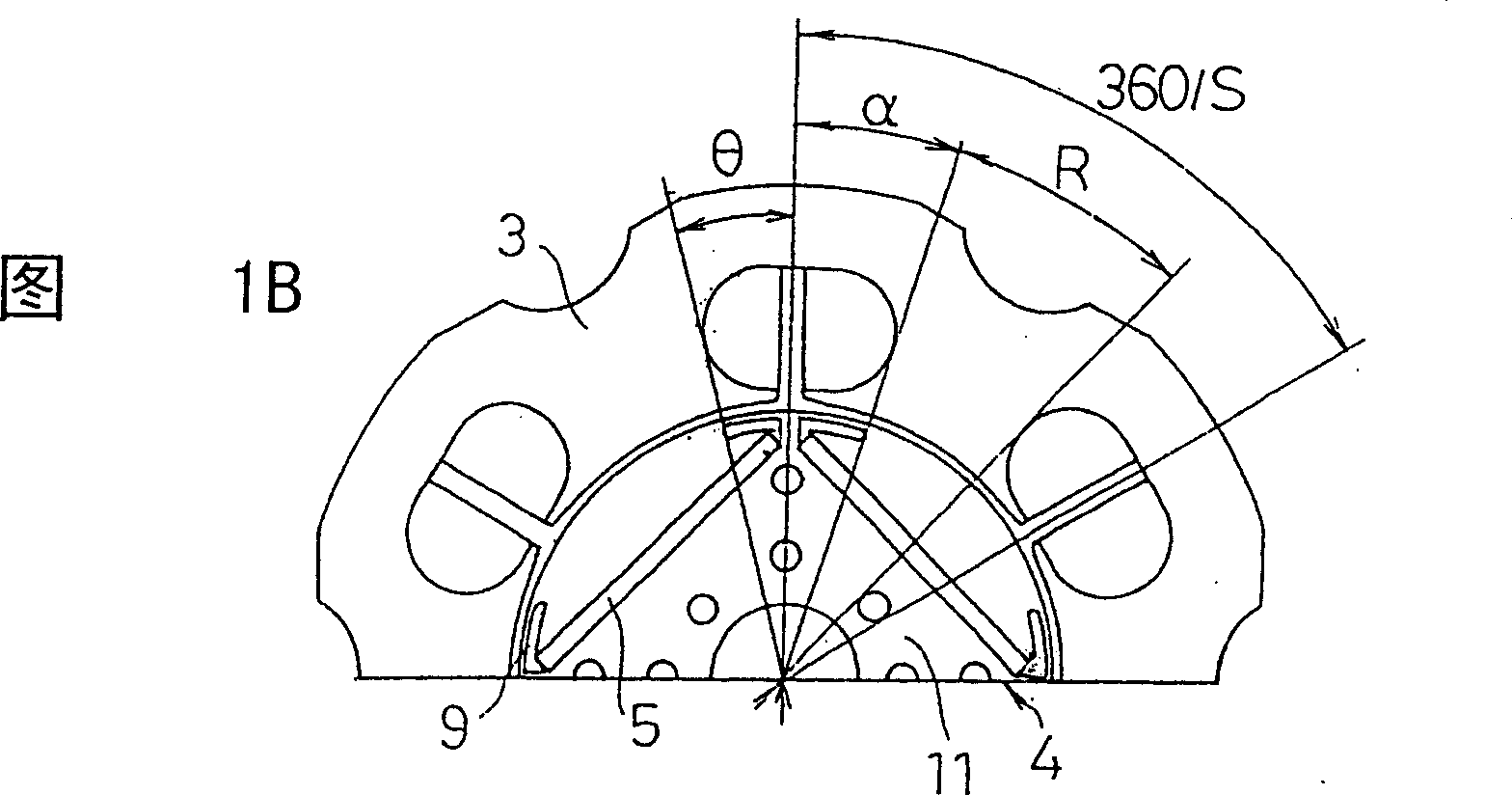

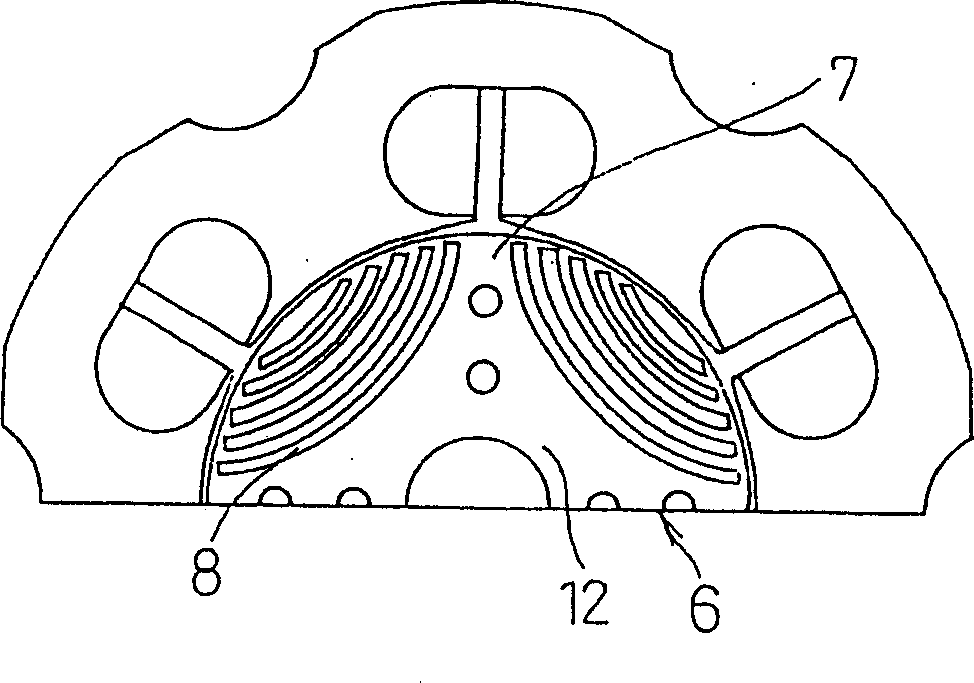

[0033] Hereinafter, a first embodiment of the motor according to the present invention will be described with reference to FIGS. 1 and 2 . The overall structure of the motor and its combination Figure 12 The descriptions made are the same, so only the main parts of the present invention will be described here.

[0034] 1A shows a part of the rotor 2 and the stator 3 of the motor 1, and the rotor 2 of the motor 1 is composed of a permanent magnet type rotor part 4 and a permanent magnet type rotor part 4 shown in FIG. 1B. Figure 1C The shown reluctance type rotor part 6 is constituted. The permanent magnet type rotor part 4 is embedded with four (2n, n=2) rare-earth magnets or iron oxides inside the rotor core 11 formed by laminating roughly circular rotor core plates formed by punching electromagnetic steel sheets. The permanent magnet 5 such as a body magnet is constituted. N poles and S poles of each permanent magnet 5 are alternately arranged in the circumferential dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com