Sewing machine controller

A control device and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, program-controlled sewing machines, etc., can solve problems such as troublesome, difficult, and sewing objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

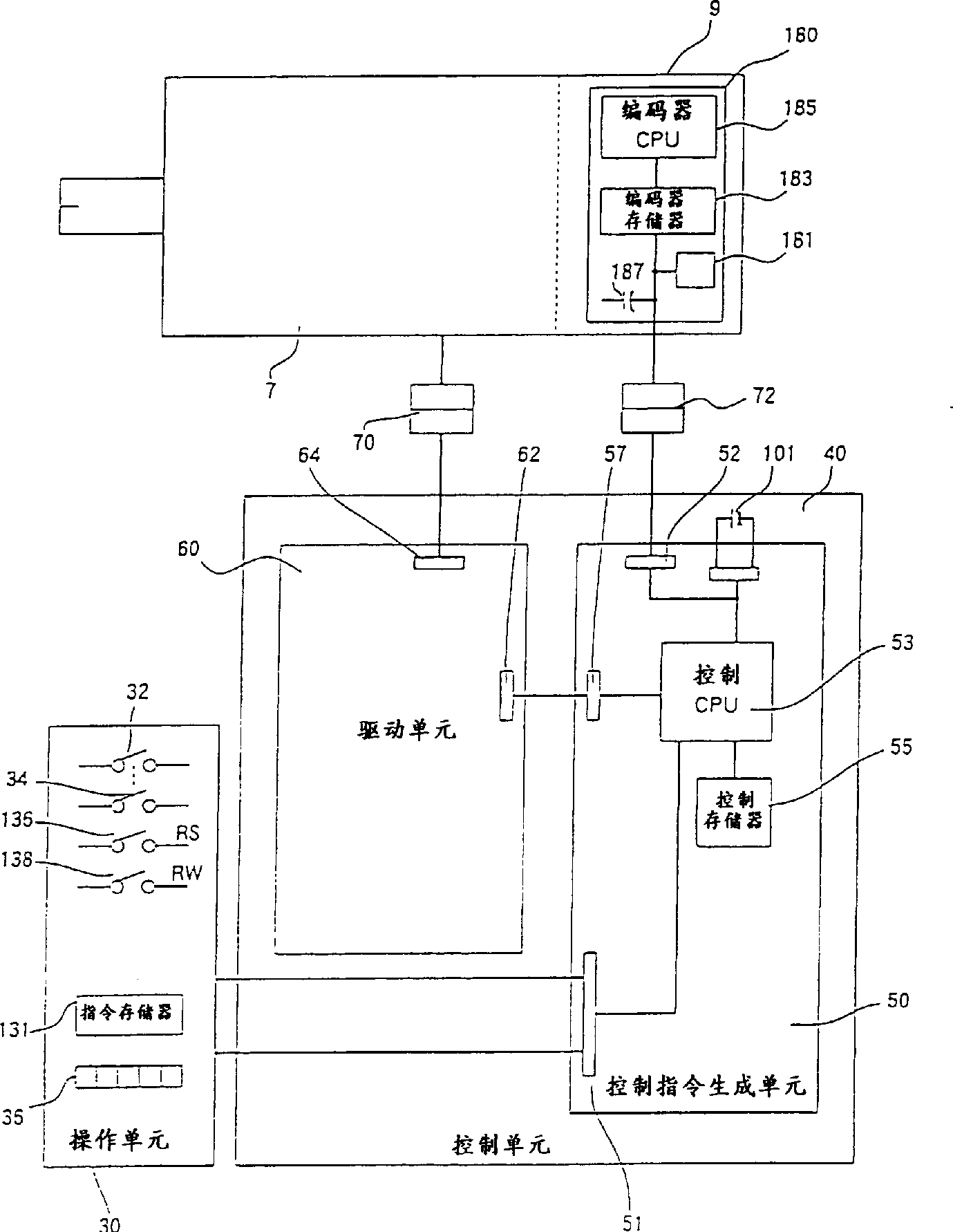

[0050] Below, refer to figure 1 Example 1 of the present invention will be described. figure 1 It shows the overall block diagram of the sewing machine control unit. exist figure 1 The same reference numerals as in the prior art denote the same or corresponding parts, and description thereof will be omitted.

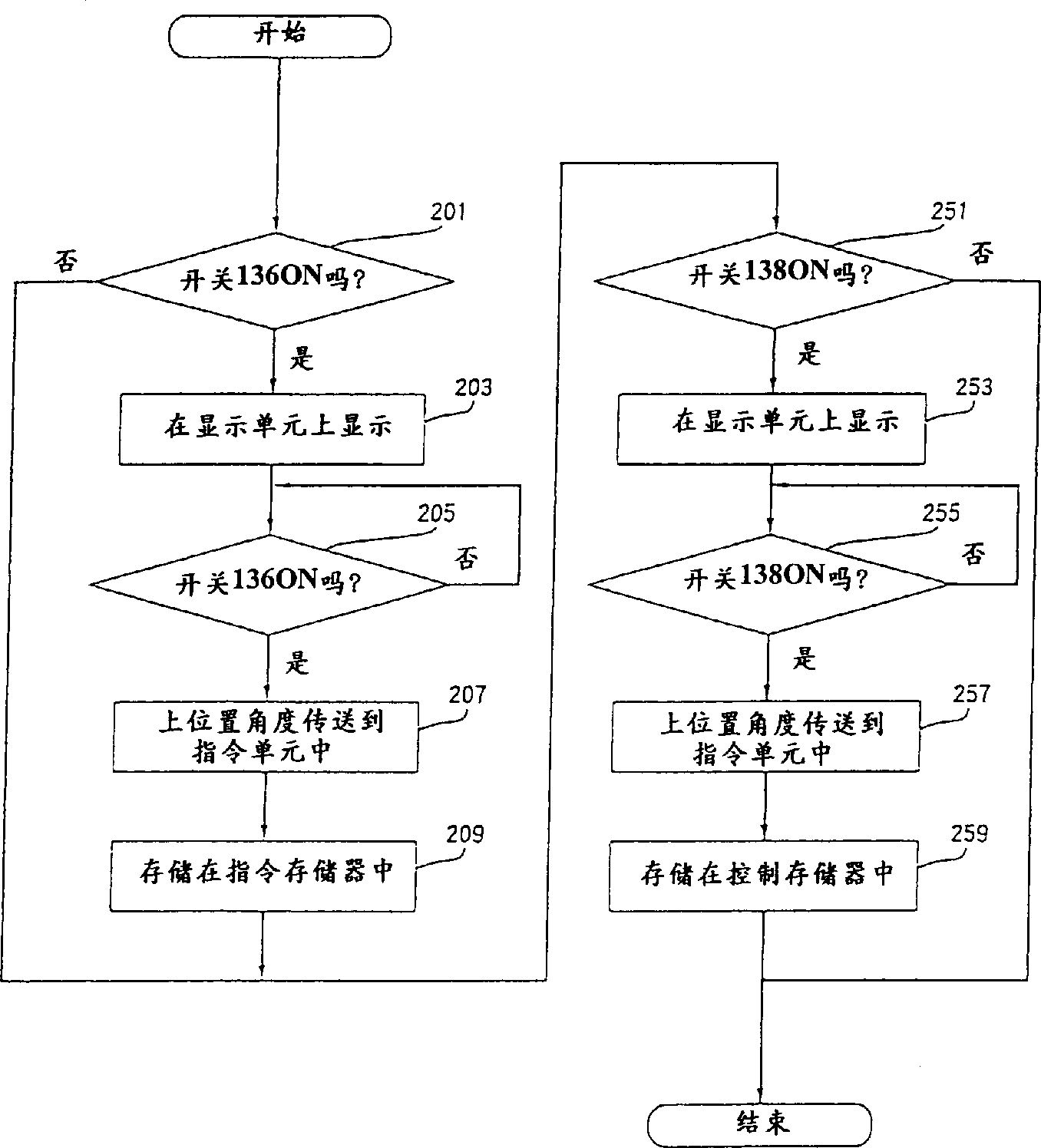

[0051] The control device of the sewing machine includes an operation unit 30 , a control unit 40 , and an encoder control unit 180 . The operation unit 30 includes an instruction memory 131 , a read switch 136 and a write switch 138 composed of electrically erasable nonvolatile storage elements.

[0052] A backup battery 101 is set in the control unit 40, and the encoder control unit 180 includes a voltage detection unit 181 for detecting whether the power supply voltage is supplied by the control unit 40, an encoder memory 183 composed of electrically erasable non-volatile storage elements, An encoder CPU 185 that controls the encoder 9 and a capacitor 187 for at...

Embodiment 2

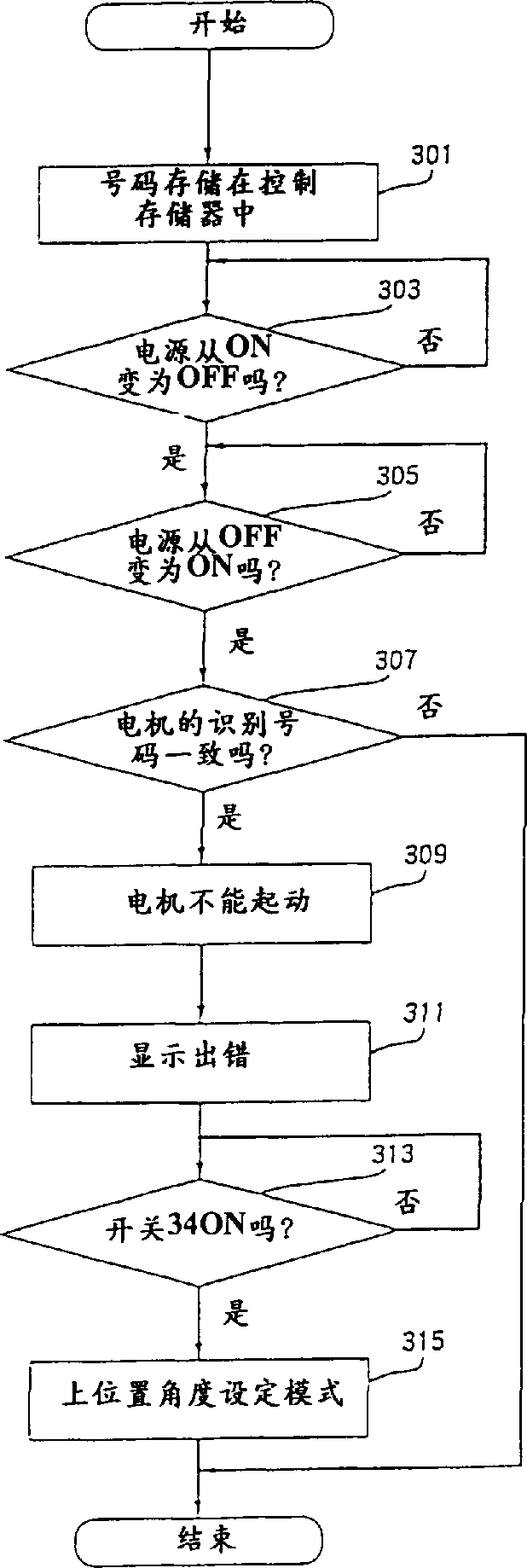

[0058] Below, refer to image 3 Other embodiments of the present invention will be described. In this embodiment, the attenuation of the voltage value of the power supply of the control unit 40 is used to detect the replacement of the motor, and then, for example, a predetermined angle of the sewing machine needle 5 is set. For example, the identification number of the motor 7 is input into an input device not shown at the time of shipment, and the identification number of the motor 7 is written into the encoder memory 183 of the motor 7 using this identification number.

[0059] Utilize power supply to turn on (ON) from disconnection (OFF), then the CPU53 of control unit reads identification number from encoder memory 183, and this number is sent in the control unit 40, and is stored in the control memory 55 ( Step 301).

[0060] Then, for some reason motor 7 breaks down, then judge whether the power supply of control unit 40 changes disconnection (OFF) (step 303) from conn...

Embodiment 3

[0063] Below, refer to Figure 4 Other embodiments of the present invention will be described. In this embodiment, for example, the voltage attenuation of the encoder control unit 180 is used to detect the replacement of the motor, and then the predetermined angle of the sewing machine needle is set.

[0064] The voltage detection unit 181 judges whether the power supply voltage value of the encoder control unit 180 has attenuated (step S401), and if it is normal, this process ends. On the other hand, in the case of attenuation, the encoder CPU 185 stores the fact that the power supply voltage value of the encoder control unit 180 is abnormal in the encoder memory 183 (step 403), and the voltage detection unit 181 judges whether the power supply voltage value is attenuated or not. becomes (OFF), and the power supply voltage value returns to normal (ON) (step 405), and if not, this process ends.

[0065] On the other hand, if recovery, then the encoder CPU185 transmits the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com