Scanning electronic microscope standard substance and its making method

An electron microscope and standard substance technology, applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems of inability to calibrate the image and inability to adapt to higher and higher resolutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

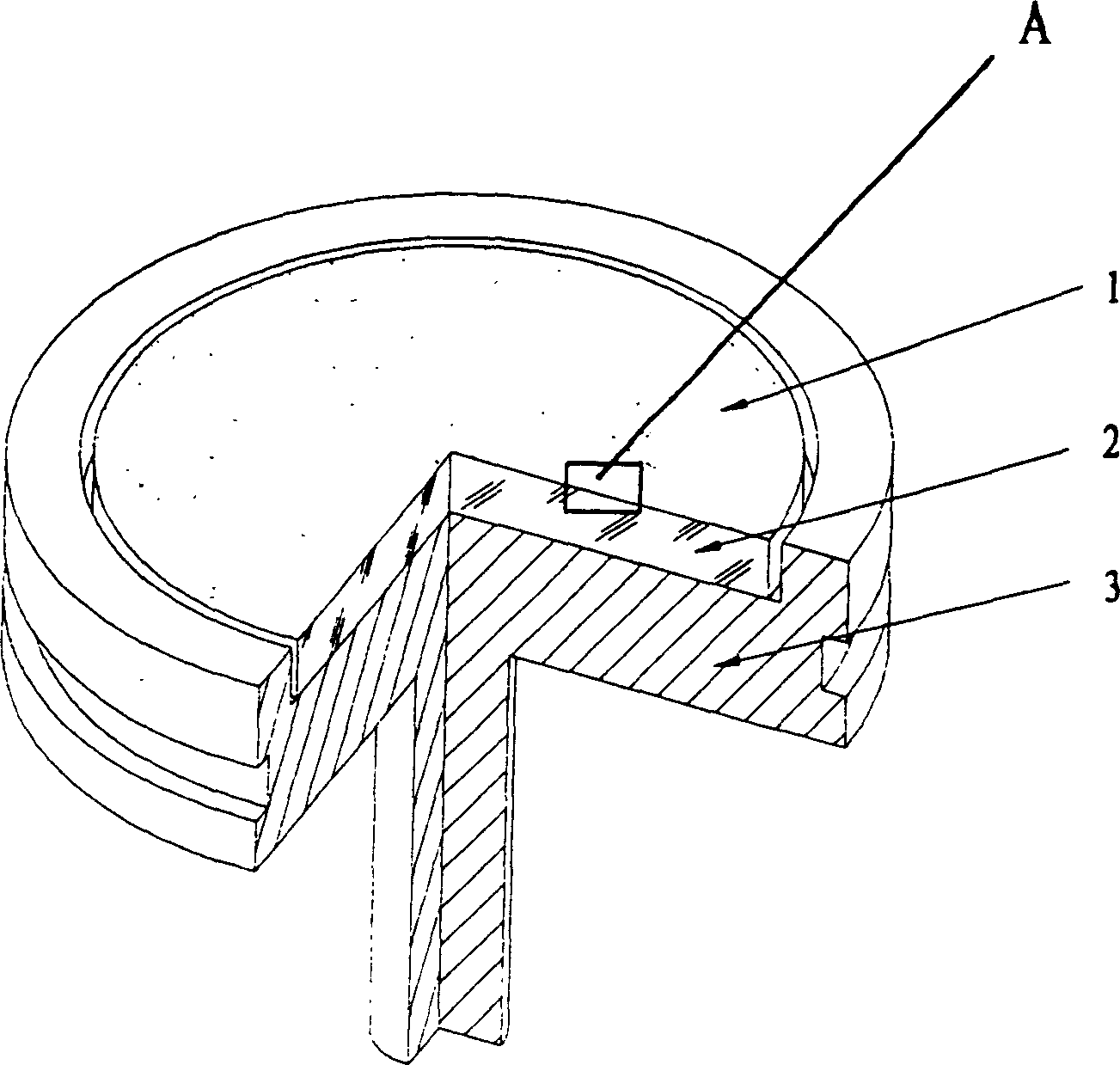

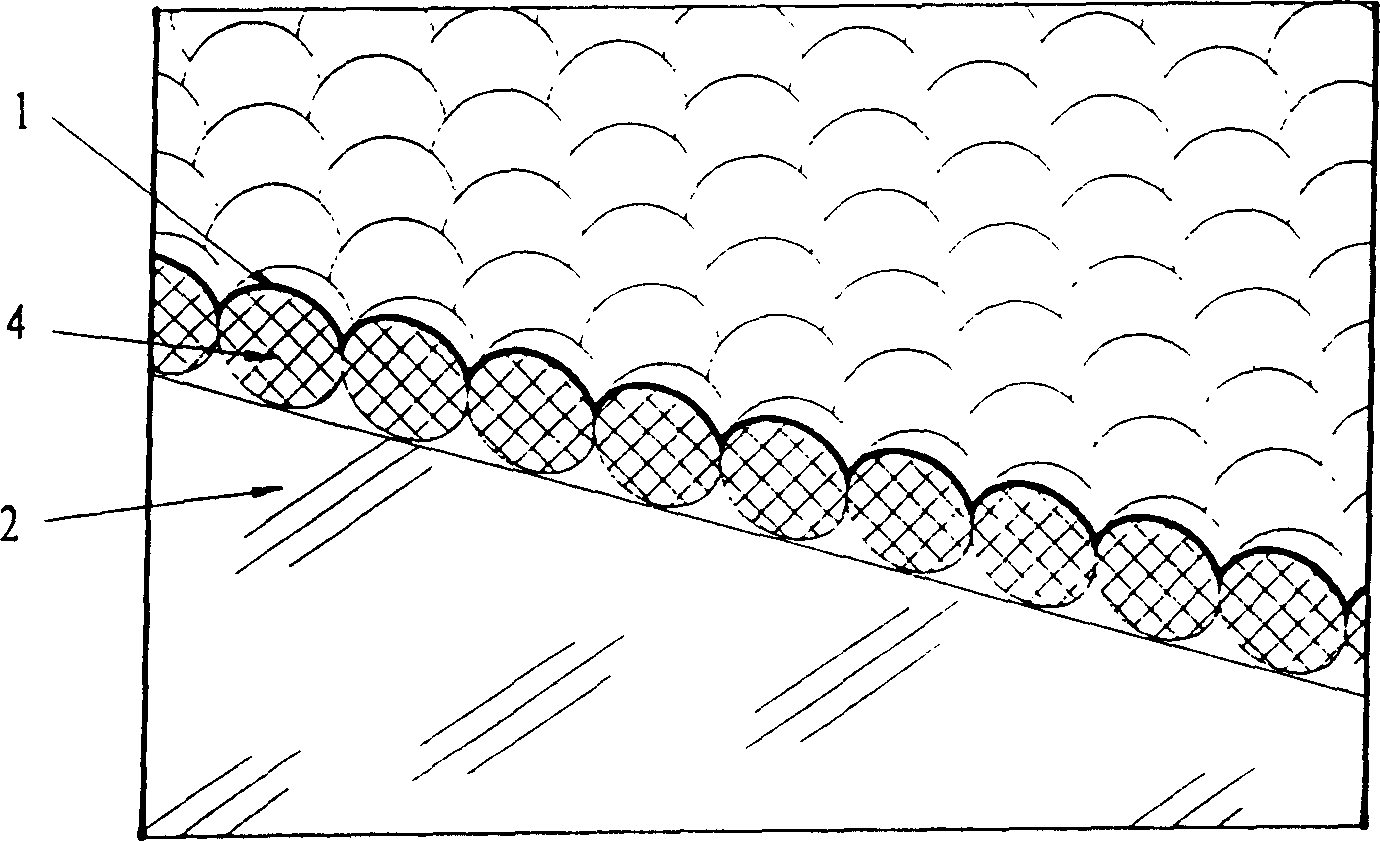

[0010] Embodiment 1: refer to figure 1 , figure 2 . The measurement film (dried monodisperse polystyrene standard particle aqueous solution) is coated on the substrate of the present invention, and then gold is plated on the measurement film to perform magnification calibration.

Embodiment 2

[0011] Embodiment 2: refer to figure 1 , figure 2 . For the convenience of calibration, the same technical effect as in Example 1 can also be achieved by placing the plated measurement film and the gold-plated substrate on the sample holder.

Embodiment 3

[0012] Embodiment 3: refer to figure 1 , figure 2 . Firstly, the physical and chemical parameters provided by Duke Science Company of the United States are selected as solid content of 1% and density of 1.05g / cm 3 , Refractive index 1.59@589nm / 23 ℃, the particle size is 0.3μm monodisperse polystyrene standard particle aqueous solution (the relative standard deviation of the monodisperse polystyrene standard particle diameter is 1.4%), and the surface roughness (Ra) is less than 20nm , a glass plate with a thickness of 1 mm and a diameter of 10 mm as the substrate; then immerse the substrate in 100% ethanol, and then use an ultrasonic cleaner to clean the substrate for 8 minutes; then drip the aqueous solution of monodisperse polystyrene standard particles On the substrate (the amount V of the aqueous solution of polystyrene standard particles in the monodisperse phase should satisfy the following formula: V=0.6Sd / p), it forms a spherical array of standard particles in a sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com