Vehicle mounted concrete transfer pump

A technology of concrete conveying pump and vehicle-mounted pump, applied in pump, pump control, liquid variable capacity machinery, etc., can solve the problems of low outlet pressure, pumping height limitation, limitation, etc., to reduce failure, reduce power loss, The powerful effect of the powertrain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

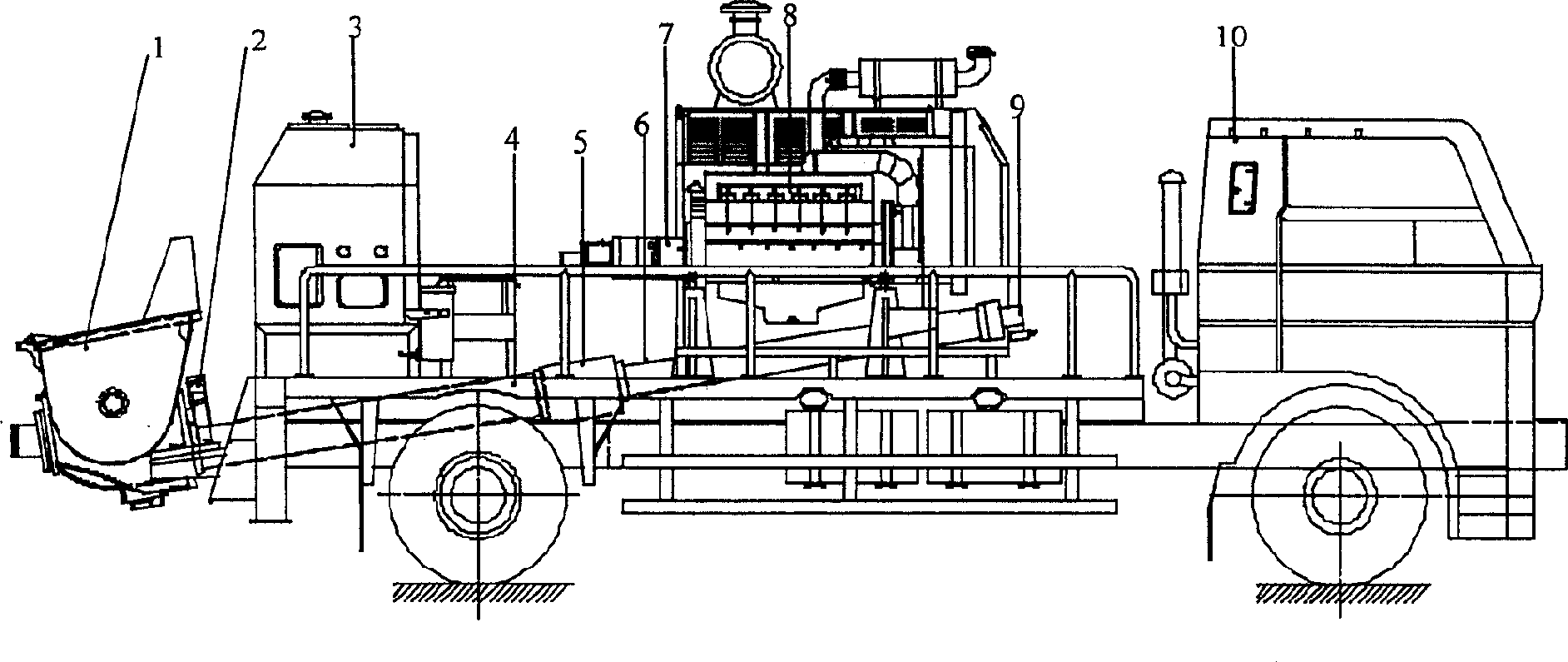

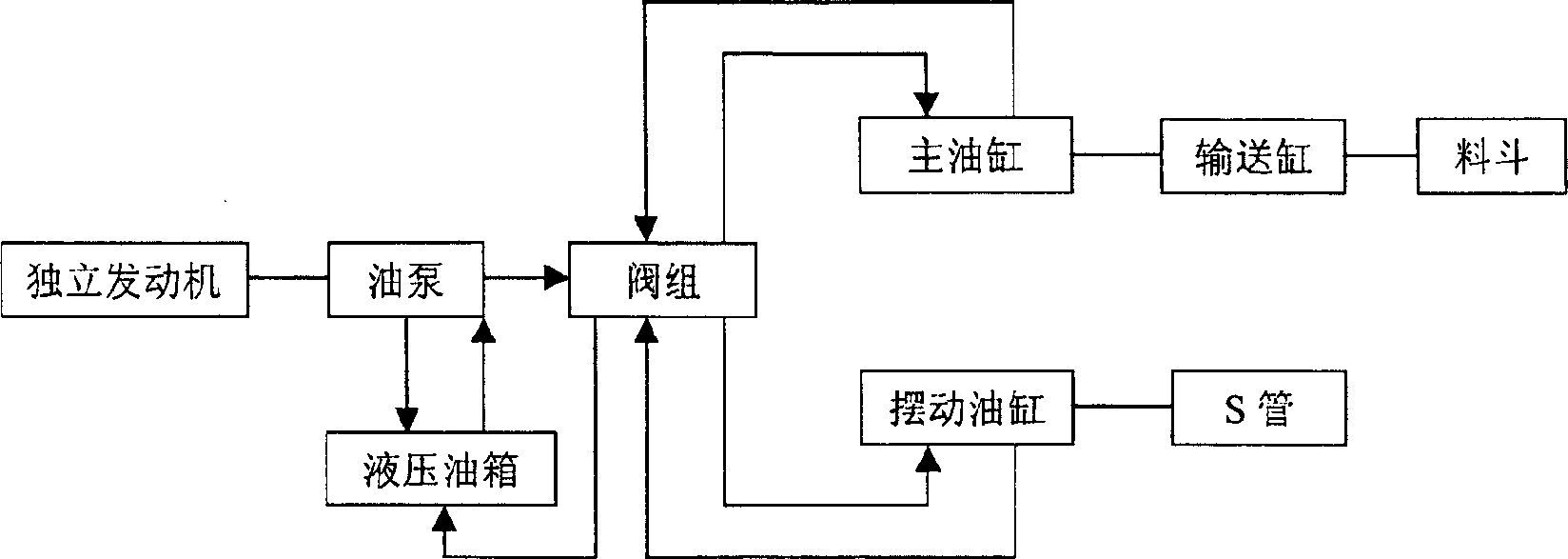

[0019] According to attached figure 1 , the HBC85 vehicle-mounted concrete delivery pump of the present invention consists of a hopper 1, a swing cylinder 2, a hydraulic oil tank 3, a delivery cylinder 4, a washing room 5, a main cylinder 6, an oil pump 7, and an independent engine 8 to form a pumping system, and is connected with the chassis 10 through mechanical The reliable connection mode is connected, and the whole machine moves along with the chassis 10 . The main oil cylinder 6 drives the piston of the delivery cylinder 4 to extend or retract together, and presses the concrete in the hopper 1 to the discharge port of the hopper 1 through the reciprocating switching of the swing oil cylinder 2 .

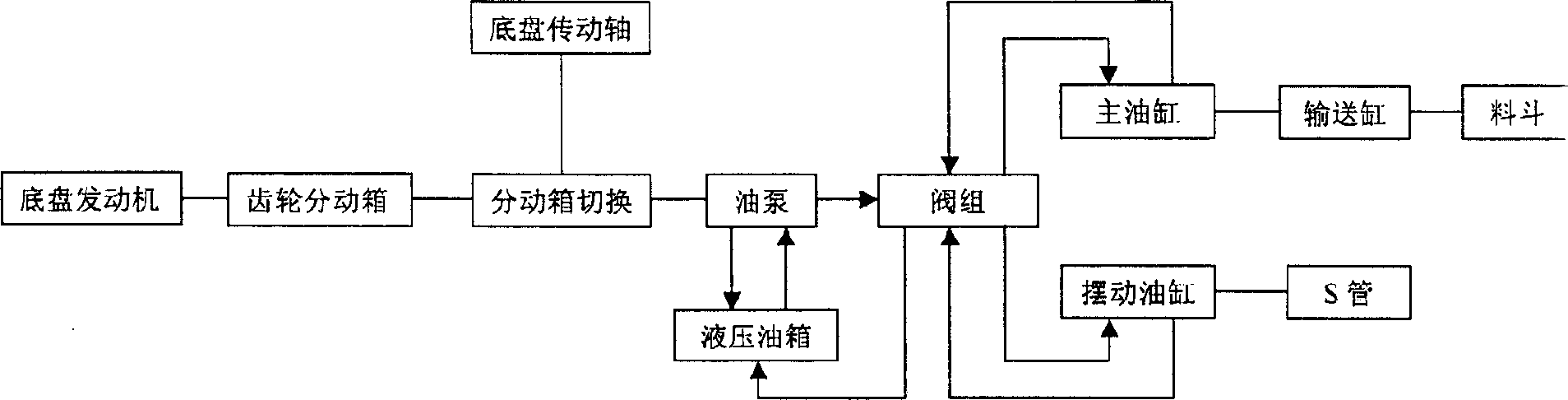

[0020] Vehicle-mounted pump technology, in terms of its structure and performance, is mainly divided into two parts: chassis and pumping system. The chassis of the HBC85 vehicle-mounted concrete delivery pump of the present invention adopts the second-class chassis of Dongfeng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com