Violet pachyrhizus wine making method

A production method and sweet potato wine technology are applied in the production field of purple sweet potato wine, which can solve the problems of no sweet potato nutrition, different tastes, different prices, etc., and achieve the effects of low cost, simple production process and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

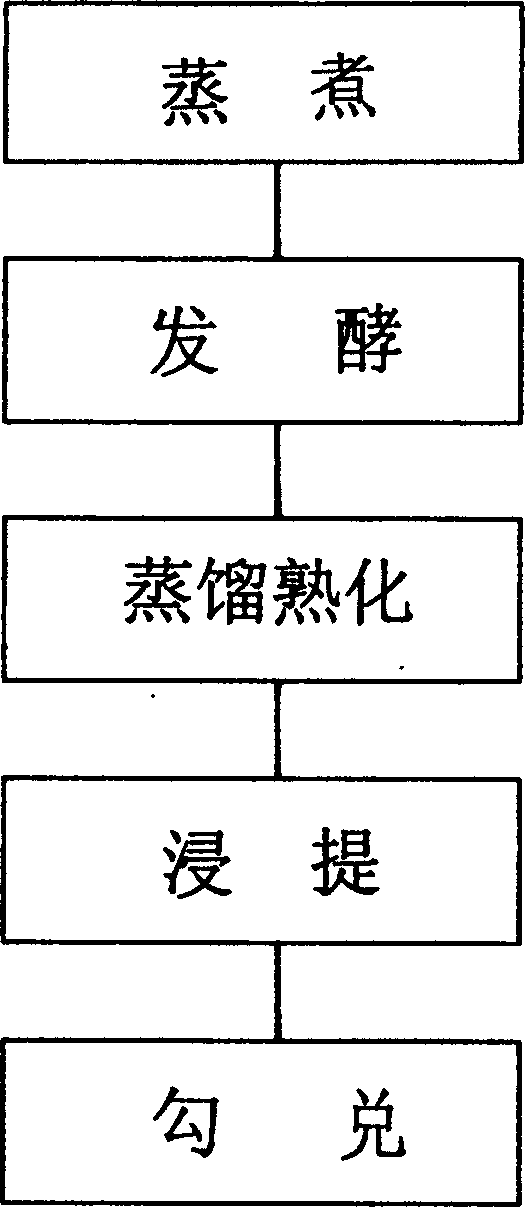

Method used

Image

Examples

Embodiment 1

[0010] Wash 100 catties of selected sweet potatoes, remove the head and tail, cook at 105°C for 1 hour, then cool to 27°C, then add 0.3 catties of koji cake and 27 catties of rice koji to the cooked sweet potatoes. Saccharify and ferment for 20 days, then add 33 catties of demineralized water to ferment for 2 days; distill the mixture of fermented sweet potatoes, koji cakes, rice koji and demineralized water at a temperature of 110°C, and the distilled liquid is It is a semi-finished sweet potato wine, and the semi-finished sweet potato wine is stored and matured for 9 months before use; the steamed purple sweet potato is added with 9% cooked purple sweet potato according to the weight ratio of the semi-finished sweet potato wine, and then filtered for 7 days; the filtered liquid is used Demineralized water is blended, and its alcohol content reaches 28 degrees, and the finished purple sweet potato wine can be obtained.

Embodiment 2

[0012] Wash 200 catties of selected sweet potatoes, remove the head and tail, cook at 105°C for 1 hour, then cool to 28°C, then add 0.8 catties of koji cake and 50 catties of rice koji to the steamed sweet potatoes. Saccharify and ferment for 23 days, then add 70 catties of demineralized water to ferment for 2 days; distill the mixture of fermented sweet potatoes, koji cakes, rice koji and demineralized water at a temperature of 105°C, and the distilled liquid is It is a semi-finished sweet potato wine, and the semi-finished sweet potato wine is stored and matured for 10 months before use; the steamed purple sweet potato is added with 9% cooked purple sweet potato according to the weight ratio of the semi-finished sweet potato wine, and then filtered for 5 days; the filtered liquid is used Demineralized water is blended, and its alcohol content reaches 28 degrees, and the finished purple sweet potato wine can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com