Utilisations of oil bodies

A technology for oil bodies and uses, applied in the field of preparing emulsions, can solve the problems of limited application range, undesired odor, fragrance, color and sensory properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Embodiment 1

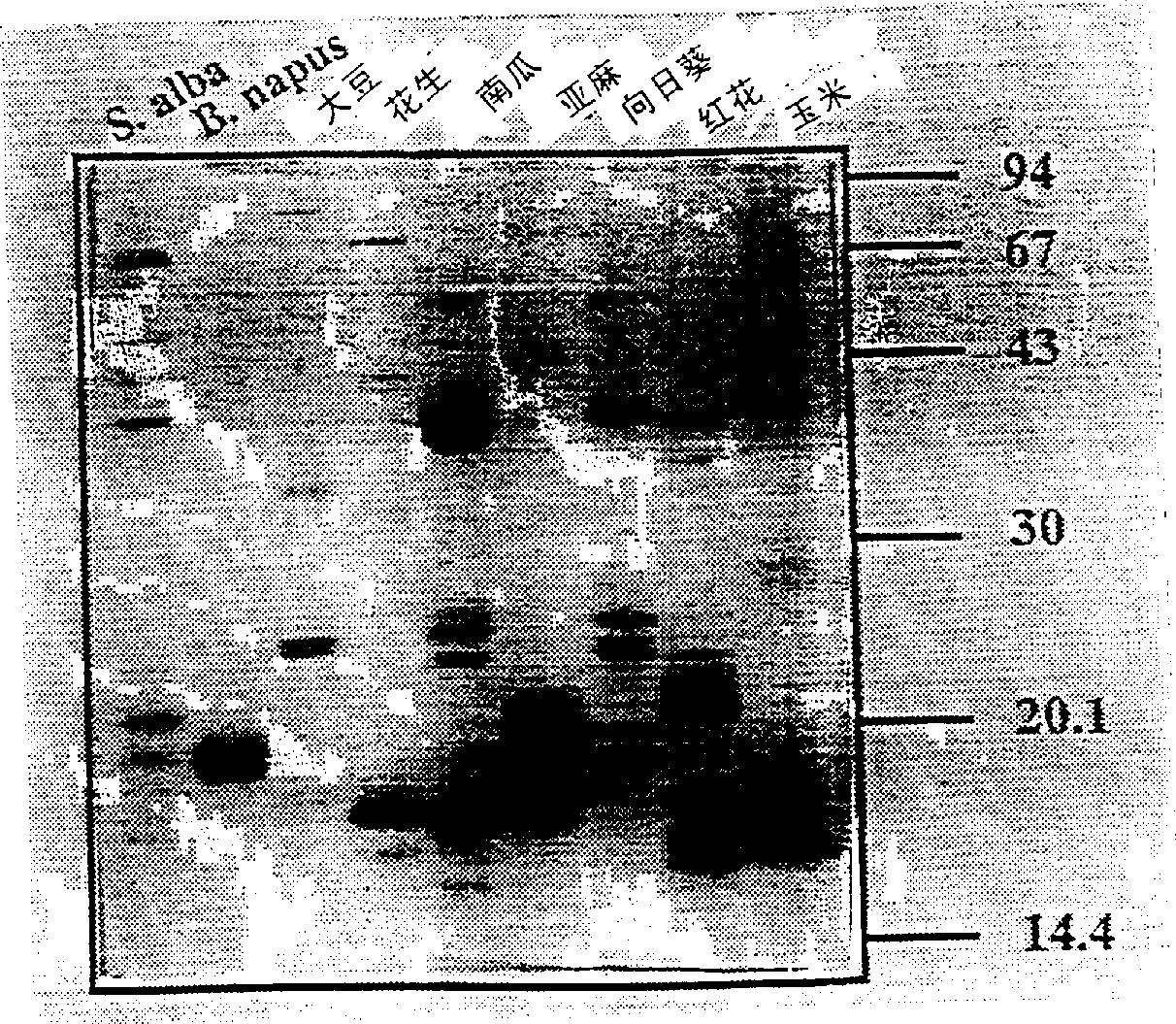

[0088] The following non-limiting examples serve to illustrate the invention. EXAMPLES Example 1 Obtaining washed oil body preparations from oilseed rape, soybean, sunflower, white mustard, peanut, pumpkin, flax, safflower and corn (laboratory scale)

[0089]Dry mature seeds obtained from oilseed rape (Brassica napus cv Wester), soybean, sunflower, white mustard, peanut, pumpkin, flax, safflower, and corn were mixed in 5 volumes of cold grinding buffer (50 mM Tris-HCl, pH 7 .5, 0.4M sucrose and 0.5M NaCl), using a polytron at high speed. The homogenate was centrifuged at 10Xg for 30 minutes to remove particulate matter and to separate the oil bodies from the aqueous phase, which contained a large amount of soluble seed protein. The oil body fraction was skimmed off the surface of the supernatant with a metal spatula and added to 1 volume of trituration buffer. In order to achieve efficient washing in subsequent steps, it was found that the oil bodies need to be sufficiently ...

Embodiment 2

[0091] The material thus obtained can be conveniently used in a variety of formulations. Example 2 Obtaining washed oil body preparations from oilseed rape, sunflower and corn on a large scale

[0092] This example describes the large scale recovery of oil body fractions from canola, sunflower and corn seeds. The resulting preparation contained intact oil bodies and was similar in purity to preparations obtained on laboratory scale. seed grinding

[0093] A total of 10-15 kg of dried oilseed rape (canola) seeds (Brasscia napus cv Wester), sunflower (Helianthus annuus ) or corn (Zeamay), the mill is equipped with MZ-120 cross-toothed rotating disk / fixed disk grinding device and top feeding hopper. Add about 50-70 liters of water from the external water pipe before grinding. The milling operation was set at pitch 1R for obtaining particles smaller than 100 microns at 18°C to 30°C. After the seeds were ground, tap water was added to the seed slurry to a final volume of 90 ...

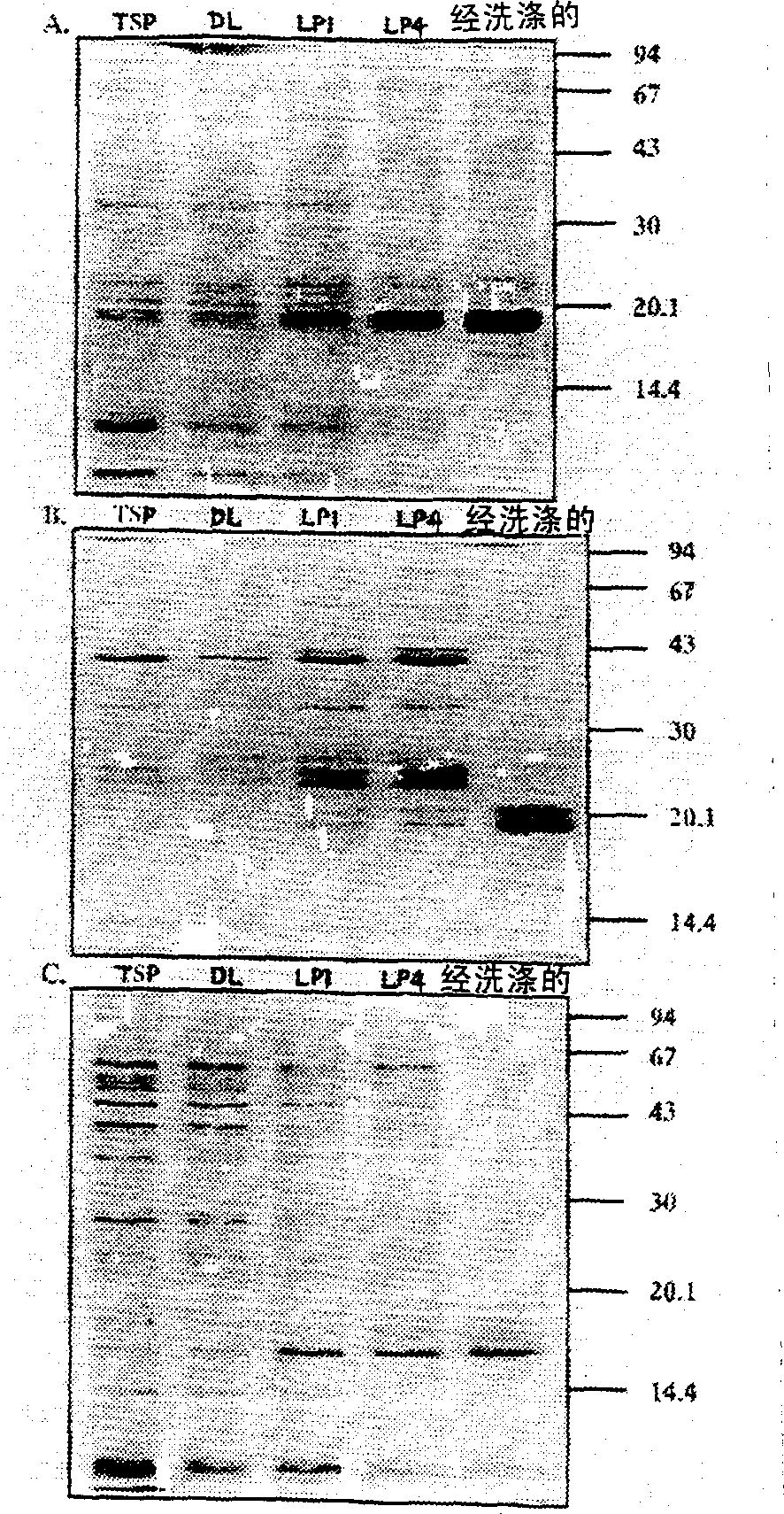

Embodiment 3

[0095] The separation of the oil body fraction is completed using a tubular centrifuge model AS-16 (Alpha Laval), which is equipped with a three-phase separation disc and a series of detachable annular retaining rings; processing capacity: 150 liters / hour; annular retaining rings Circle: 30mm. The operating speed is 15,000 rpm (13,200Xg). After the centrifuge had reached operating speed, the decanted liquid phase (DL) was pumped into the tube centrifuge using a Watson-Marlow (Model 704) peristaltic pump. This causes the decanted liquid phase to be divided into a heavy phase (HP) containing water and soluble seed proteins and a light phase (LP) containing oil bodies. The oil body fraction obtained after one pass through the centrifuge is called unwashed oil body preparation. The oil body fraction was then centrifuged three more times. Prior to each pass through the centrifuge, the concentrated oil bodies were mixed with approximately 5 volumes of fresh water. All processes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com