Component of polyaddition catalyst, polyaddition catalyst and process for preparing addition polymer

A technology of catalysts and compounds, applied in the field of preparation of addition polymers, which can solve problems such as undisclosed components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0144] An autoclave having an inner volume of 400 ml equipped with a stirrer was dried under vacuum and replaced with argon, 190 ml of cyclohexane as a solvent and 10 ml of 1-hexene as a comonomer were added, and the autoclave was heated to 70°C . After heating, add ethylene, while adjusting the pressure of ethylene to 6kg / cm 2 . After the system is stable, add 0.25 mmol triisobutylaluminum, continuously add 1.0 μmol ethylene bis(indenyl) zirconium dichloride, then add 86.5 mg (101 μmol) of complex A with the following structure, and start polymerization . Polymerization was allowed to proceed for 30 minutes.

[0145] As a result of the polymerization, 18.6 g of an ethylene-1-hexene copolymer was obtained. The polymerization activity is 3.7×10 7 g / mol / h, SCB was 19.37, [η] was 1.29 dl / g, Mw was 88000, and Mw / Mn was 2.6.

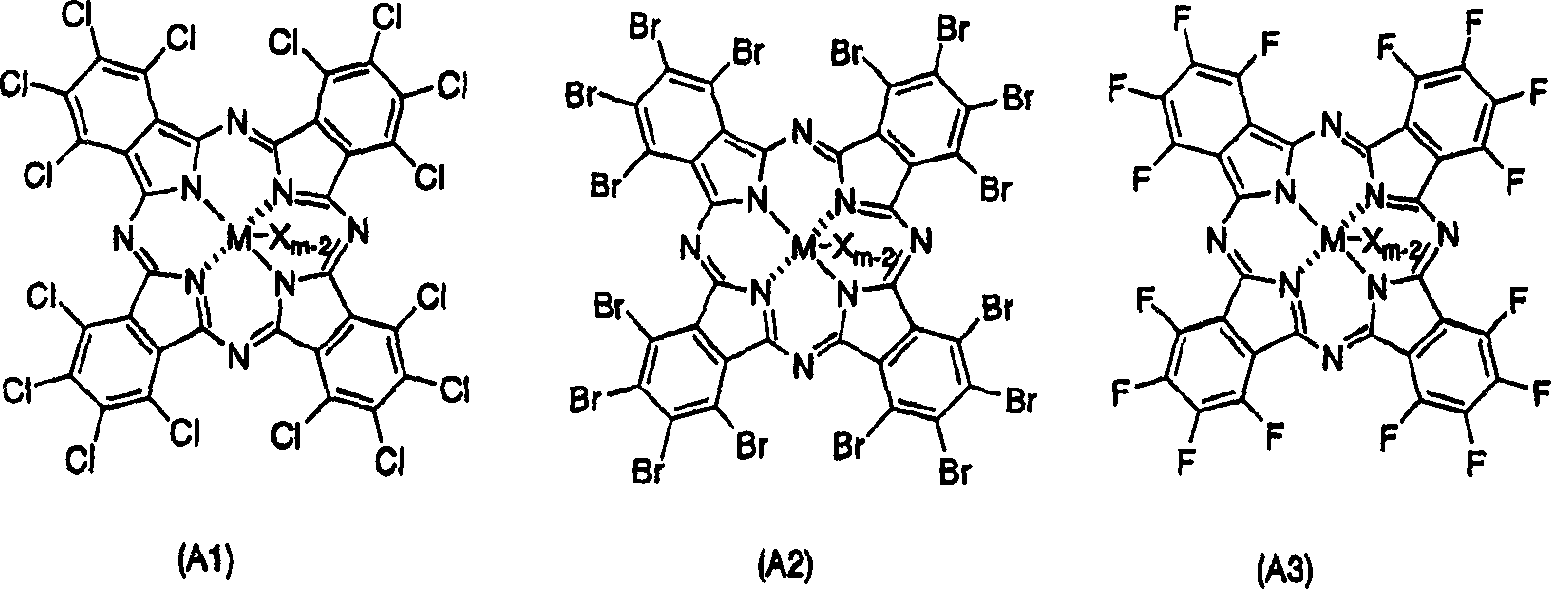

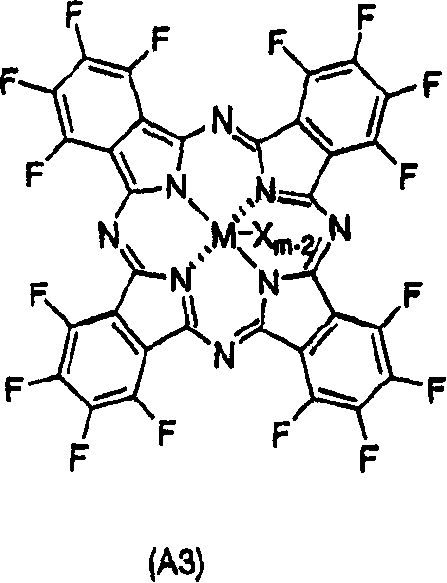

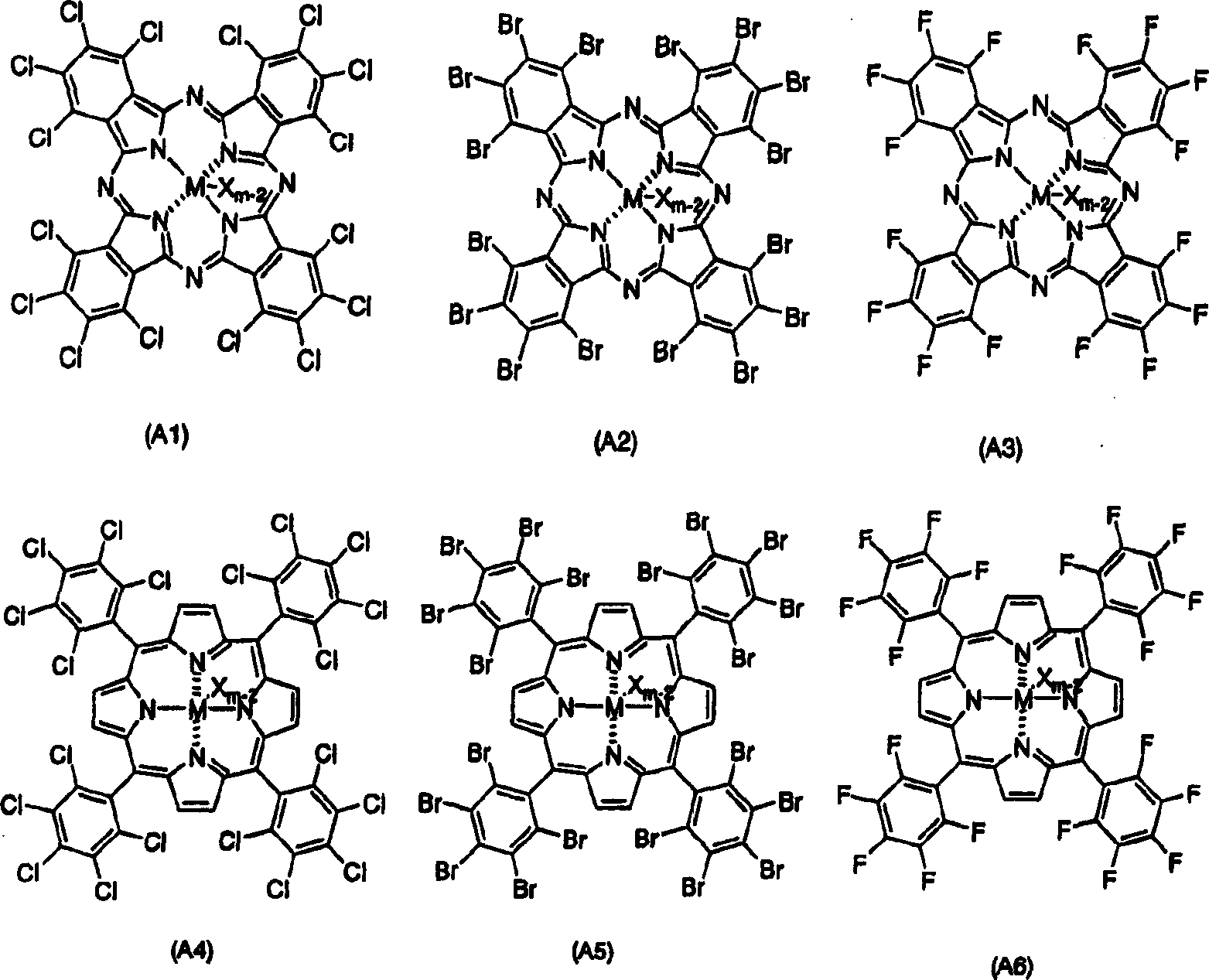

[0146] Complex A:

[0147]

[0148] Manufactured by Aldrich Co., Ltd.

[0149] The orbital coefficient of the valence P-type atomic orbital is 0.8...

Embodiment 2

[0153] An autoclave having an inner volume of 400 ml equipped with a stirrer was dried under vacuum and replaced with argon, 190 ml of cyclohexane as a solvent and 10 ml of 1-hexene as a comonomer were added, and the autoclave was heated to 70°C . After heating, add ethylene, while adjusting the pressure of ethylene to 6kg / cm 2 . After the internal stabilization of the system, 0.25 mmol of triisobutylaluminum was added, and 77.1 mg (89.7 μmol) of complex A used in Example 1 was added continuously. After stirring for 30 minutes, 1.0 μmol of ethylenebis(indenyl)zirconium dichloride was added, and polymerization was carried out for 30 minutes.

[0154] As a result of the polymerization, 20.79 g of an ethylene-1-hexene copolymer was obtained. The polymerization activity is 4.2×10 7 g / mol / h.

Embodiment 3

[0156] Polymerization was performed in the same manner as in Example 1 except that 84.6 mg (97.7 μmol) of complex B having the following structure was used instead of complex A used in Example 1.

[0157] As a result, 2.46 g of an ethylene-1-hexene copolymer was obtained. The polymerization activity is 4.9×10 6 g / mol / h, [η] was 1.28dl / g, Mw was 73000, and Mw / Mn was 1.9.

[0158] Complex B:

[0159]

[0160] Manufactured by Aldrich Co., Ltd.

[0161] The orbital coefficient of the valence P-type atomic orbital is 0.773, and the orbital energy is 0.0049. Calculation was carried out in the same manner as complex A above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com