Pulse pipe refrigerating machine and cryopump using refrigerating machine

A pulse tube refrigerator, cryogenic pump technology, applied in refrigerators, gas cycle refrigerators, refrigeration and liquefaction, etc., can solve problems such as rising prices and complex mechanisms, and achieve lower device prices, reduce failure frequency, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

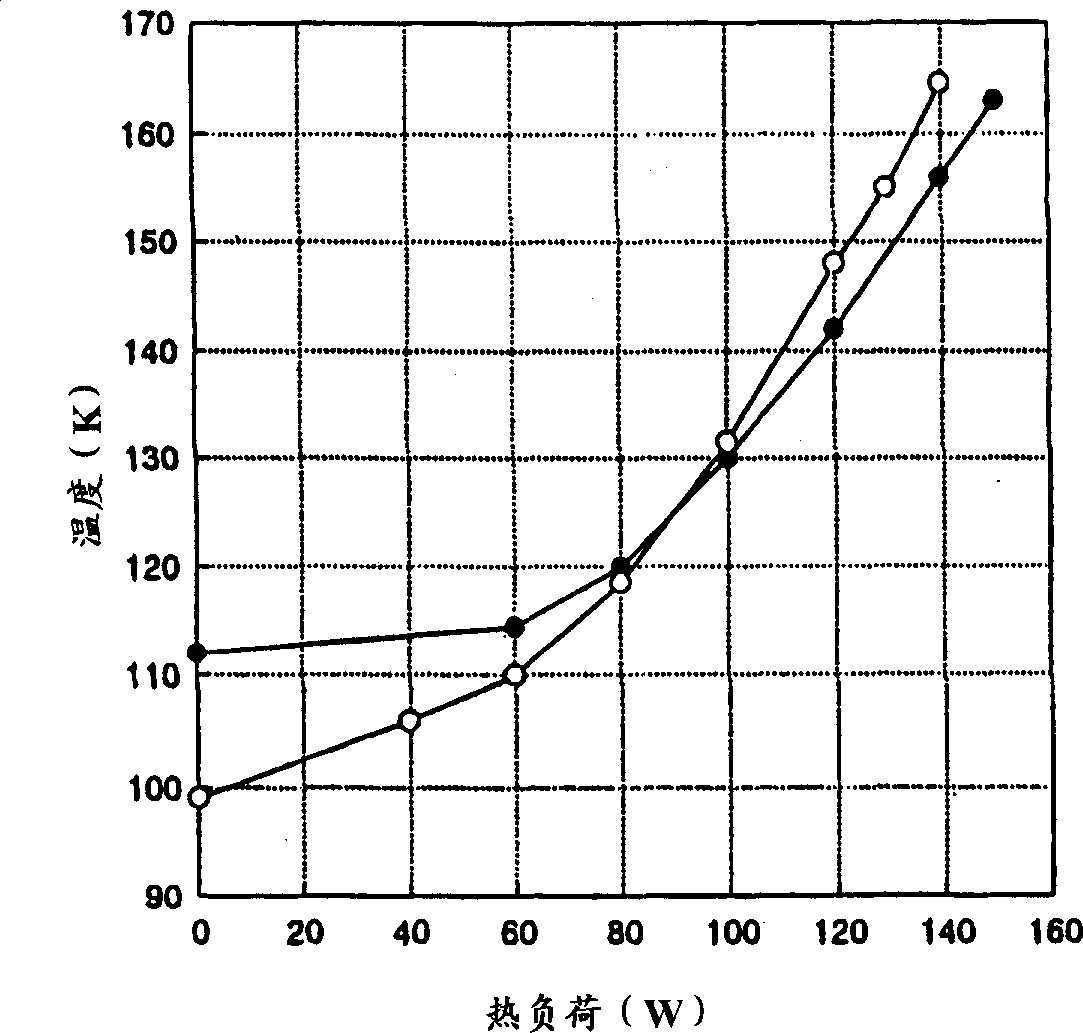

[0019] In the same cryopump as the above embodiment, the filling absolute pressure is 18.0kgf / cm 2 Nitrogen is used as the working gas. When the pulse tube refrigerator is operated, it passes through the heater installed at the cold end (this is installed for the experiment to apply the heat load), and the temperature change of the cold end when the heat load is applied is investigated. . The result is as figure 2 shown (measurement results are shown in black circles). Depend on figure 2 It can be seen that the temperature maintenance effect due to the liquefaction of the working gas can be achieved, and the cooling temperature can be maintained in the range of 112-115K when the heat load is 0-60W. Also, nitrogen at 16.4kgf / cm 2 When the liquefaction temperature is 112K.

Embodiment 2

[0021] In the same cryopump as in the above-mentioned embodiment, the partial pressure of filling nitrogen gas is 14.4kgf / cm 2 And helium is 3.6kgf / cm 2 As the working gas, the pulse tube refrigerator was operated in the same manner as in Example 1, and passed through the heater installed at the cold end (this was installed for the experiment to apply a heat load), and the cooling effect when a heat load was applied was investigated. temperature change at the tip. The result is as figure 2 shown (measurement results are shown in white circles). Depend on figure 2 It can be seen that the temperature maintenance effect due to the liquefaction of the working gas can be achieved, and the cooling temperature can be maintained in the range of 99-110K when the heat load is between 0-60W. In Example 2, nitrogen and helium are in gas-liquid equilibrium, so compared with Example 1, the attainable temperature is lower. Also, nitrogen at 14.7kgf / cm 2 When the liquefaction temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com