Composite coagulant, preparation method thereof, bean curd made thereby and method for making the bean curd

A technology of coagulant and tofu, which is applied in application, food preparation, food science, etc., can solve the problems of fragility, high cost, soft and rotten texture, etc., and achieve the effect of safe and reliable eating, strong practicability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

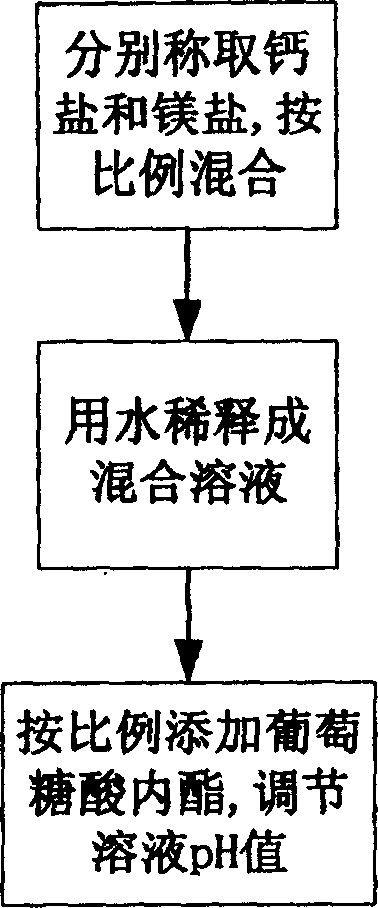

[0032] Such as figure 1 Shown is the process flow chart of making composite coagulant. From figure 1 It can be seen that the compound coagulant for making tofu is composed of calcium salt, magnesium chloride or bittern and glucono lactone. The mixing ratio is: calcium salt: 1-3 parts, magnesium salt: 1 part, glucono lactone : 0.1-0.3 parts.

[0033] The calcium salt is gypsum or calcium sulfate or calcium sulfate with crystal water.

[0034] Weigh calcium salt and magnesium chloride or bittern and mix, the mixing ratio is 1:1, 2:1, 3:1, dilute with 6 times of water to form a mixed solution; add gluconolactone to the mixed solution, the addition ratio is 0.1-0.3 times of magnesium chloride or bittern, so that the pH of the mixed solution is in the range of 4.0-6.5.

[0035] Specifically, in this example, weigh gypsum or calcium sulfate, brine or magnesium chloride and gluconolactone in a ratio of 2.5:1:0.2 to obtain a composite coagulant, and the pH of the mixture is in the range...

Embodiment 2

[0048] Weigh 5g, 7.5g, 10g of calcium sulfate (or gypsum) respectively, weigh the magnesium chloride according to the ratio of calcium sulfate and magnesium chloride of 1:1, 2:1, 3:1, mix, dilute with 6 times water, and then add 0.5 -1.0g gluconolactone, dissolved. Weigh 0.3 kg of soybeans for pulping and boiling, and evenly add them to the cooked soybean milk at 80-90°C when the brain is pounded, and go through the processes of squatting, breaking the brain, squeezing the brain, and pressing and forming to obtain the finished tofu. The moisture content of each sample is between 67%-80%, and the elasticity range is 0.5-1.8cm. The hardness is measured by a probe with a diameter of 5mm. The hardness of the sample is 0.2-0.4kg. The prepared elastic tofu does not have the sour taste of lactone tofu. .

[0049] The other process steps and conditions in this embodiment are basically the same as those in the embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com