Slide fastener tape and slide fastener stringer using the same tape

A zipper tape and zipper technology, applied in applications, clothing, fasteners, etc., can solve the problems of reduced strength and increased zipper production costs, and achieve the effect of preventing wrinkles and bending and stabilizing pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

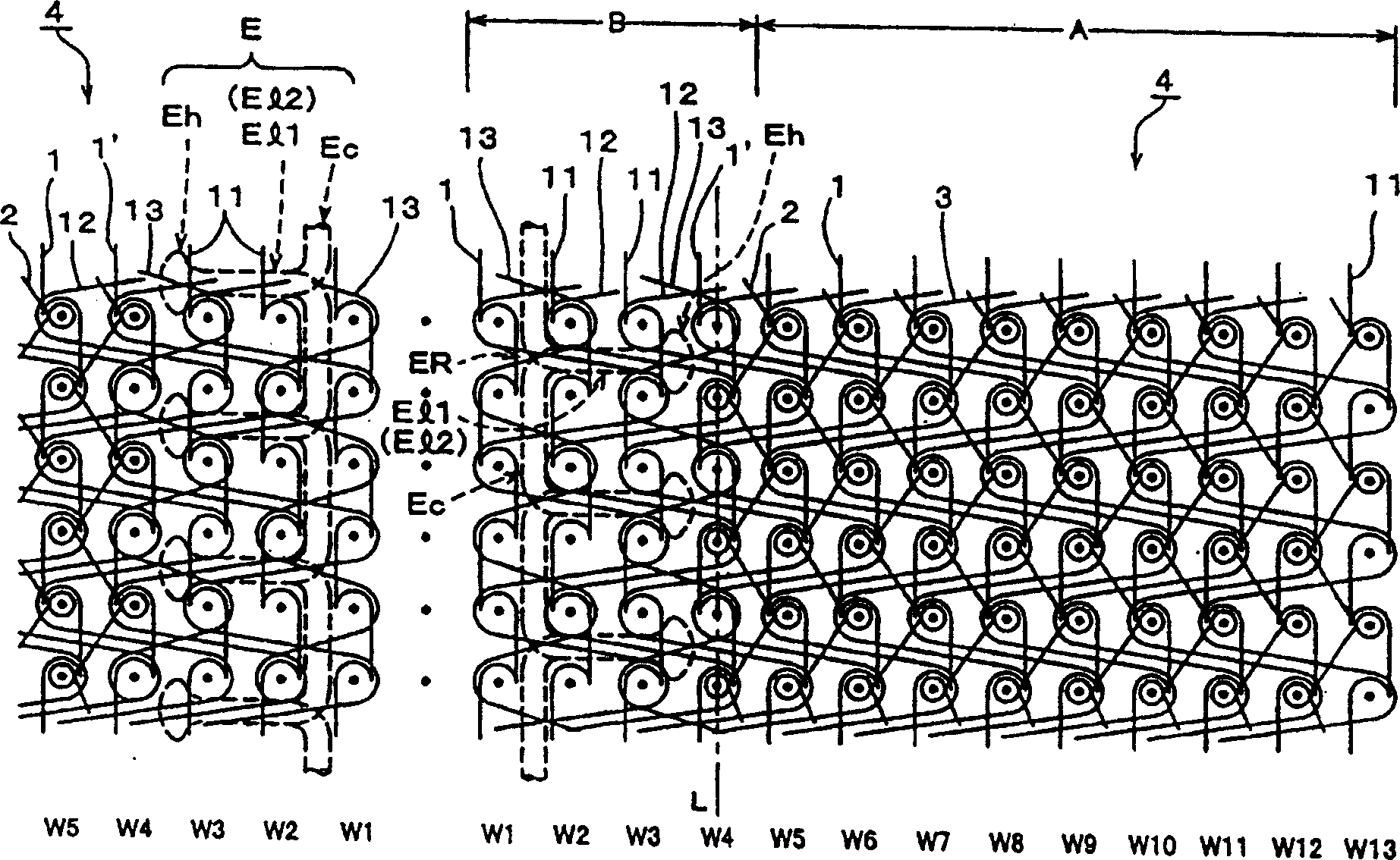

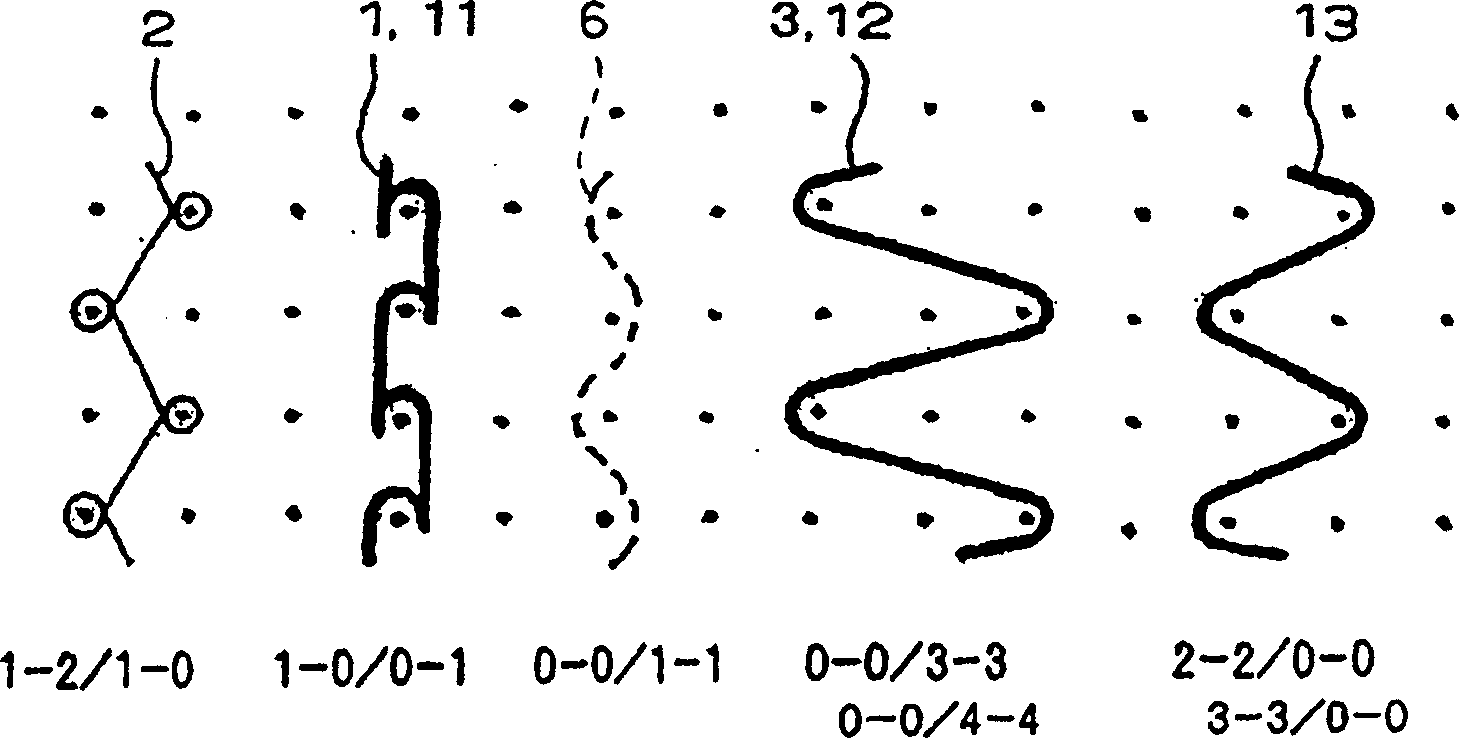

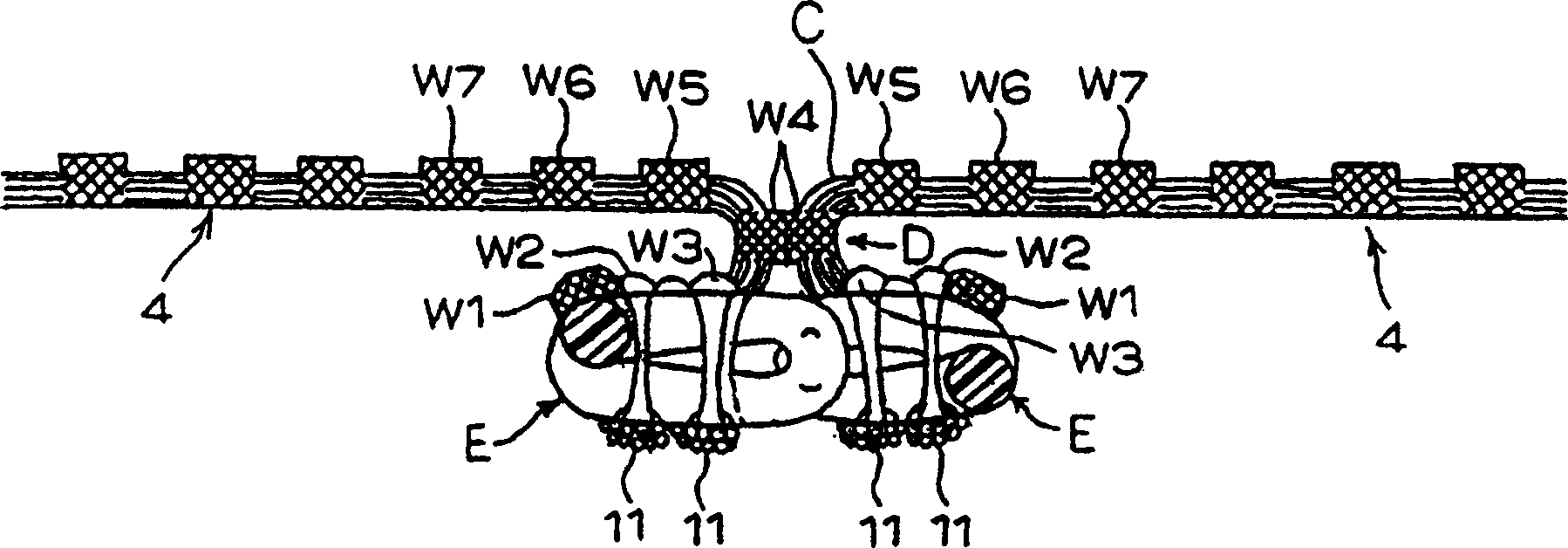

[0034] The woven-in concealed slide fastener in the present invention is knitted by a warp knitting machine such as a Russell knitting machine, which has a row of needle beds such as figure 2 As shown in , the basic structure of its zipper tape main body A consists of 1-0 / 0-1 chain knitting yarn 1, 1-2 / 1-0 warp knitting yarn 2 and 0-0 / 3-3 interlining The weft-knitting yarn 3 is constituted, and the weft-inserted knitting yarn 3 is inserted in a zigzag pattern across three wales (wales) W of the fastener tape 4 . A zipper fastening element additionally connects (attachment) portion B by three wales W on the longitudinal edge portion of each zipper tape 4 of a pair of left and right zipper tapes 4, 4. 1 -W 3 Composition, excluding 1-2 / 1-0 warp knit yarn, but including 1-0 / 0-1 fixed chain knit yarn 11, 0-0 / 3-3 weft inserted knit yarn 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com