Mask type read-only memory low heat budget making technology

A technology of read-only memory and manufacturing process, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as complicated methods, increased manufacturing costs, and manufacturing process time, so as to avoid pollution, increase margins, and reduce The effect of thermal budget

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

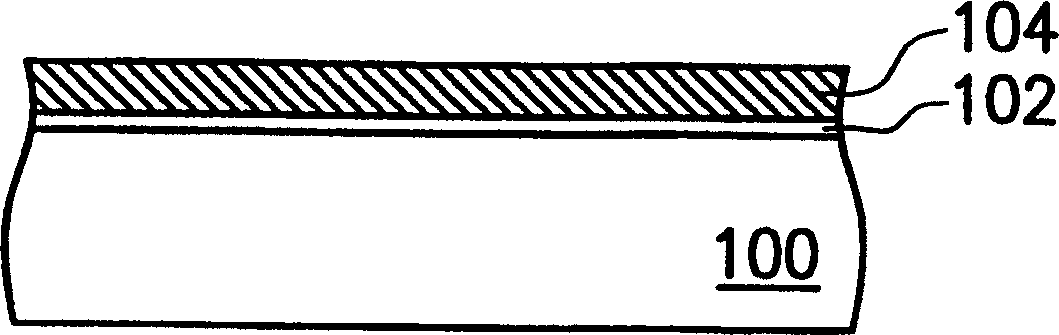

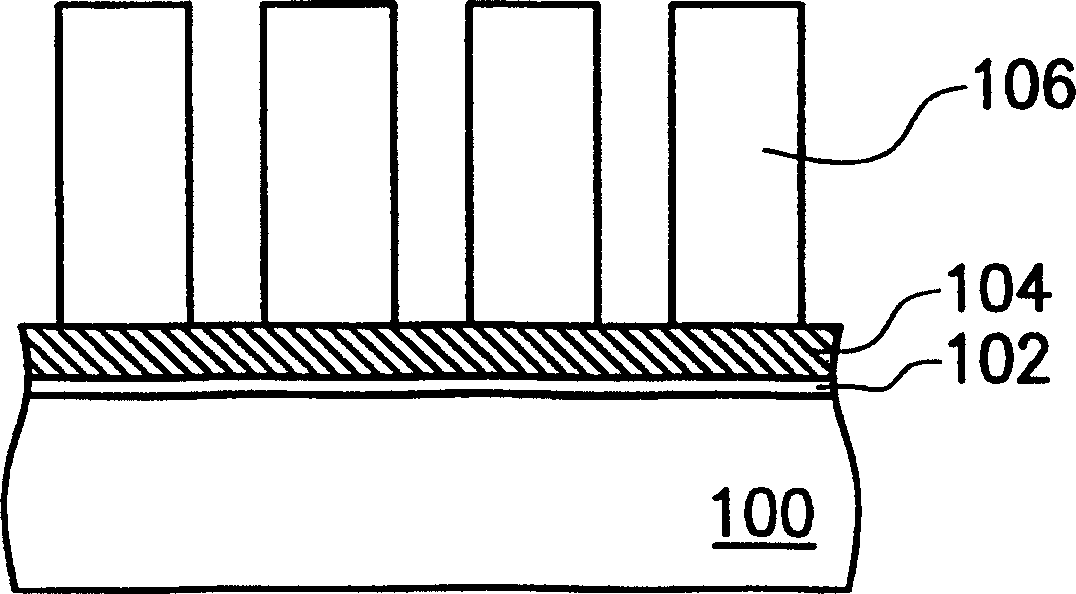

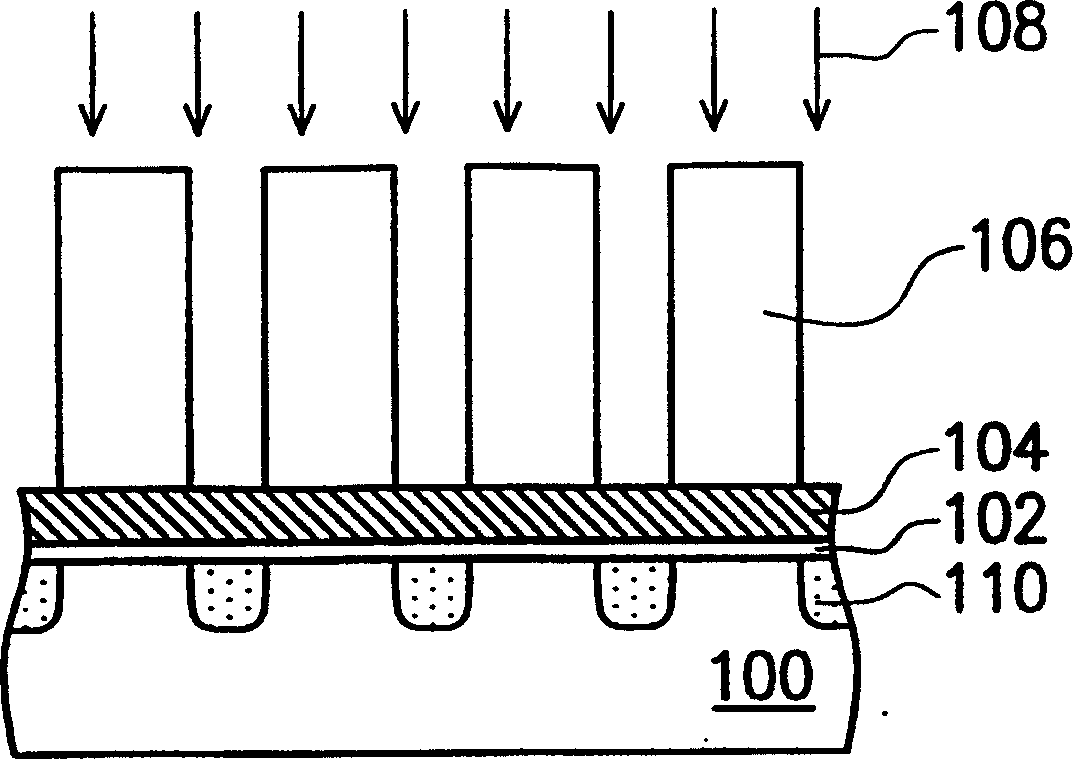

[0022] Figure 1A to Figure 1F A cross-sectional view of a manufacturing process of a mask read only memory (Mask ROM for short) low thermal budget manufacturing process according to an embodiment of the present invention.

[0023] Please refer to Figure 1A Firstly, a gate oxide layer (gate oxide) 102 is formed on a substrate 100, wherein the thickness of the gate oxide layer 102 is, for example, about 30 angstroms. Then, a first conductive layer 104 is formed on the gate oxide layer 102, the thickness of which is, for example, between 50 angstroms and 200 angstroms, and its material is, for example, polysilicon.

[0024] Then, please refer to Figure 1B , forming a first patterned photoresist layer 106 on the substrate 100 and exposing part of the first conductor layer 104 . In addition, before forming the photoresist layer 106 , a layer of bottom antireflection coating (BARC for short) may be formed on the first conductive layer 104 .

[0025] Then, please refer to Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com