High-power high-temperature superconducting mini filter

A high-temperature superconducting and filter technology, applied in the field of electronics, can solve the problems of cost reduction and convenient use, disadvantage, large filter size, etc., and achieve the effect of simple structure, easy implementation, and small passband fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

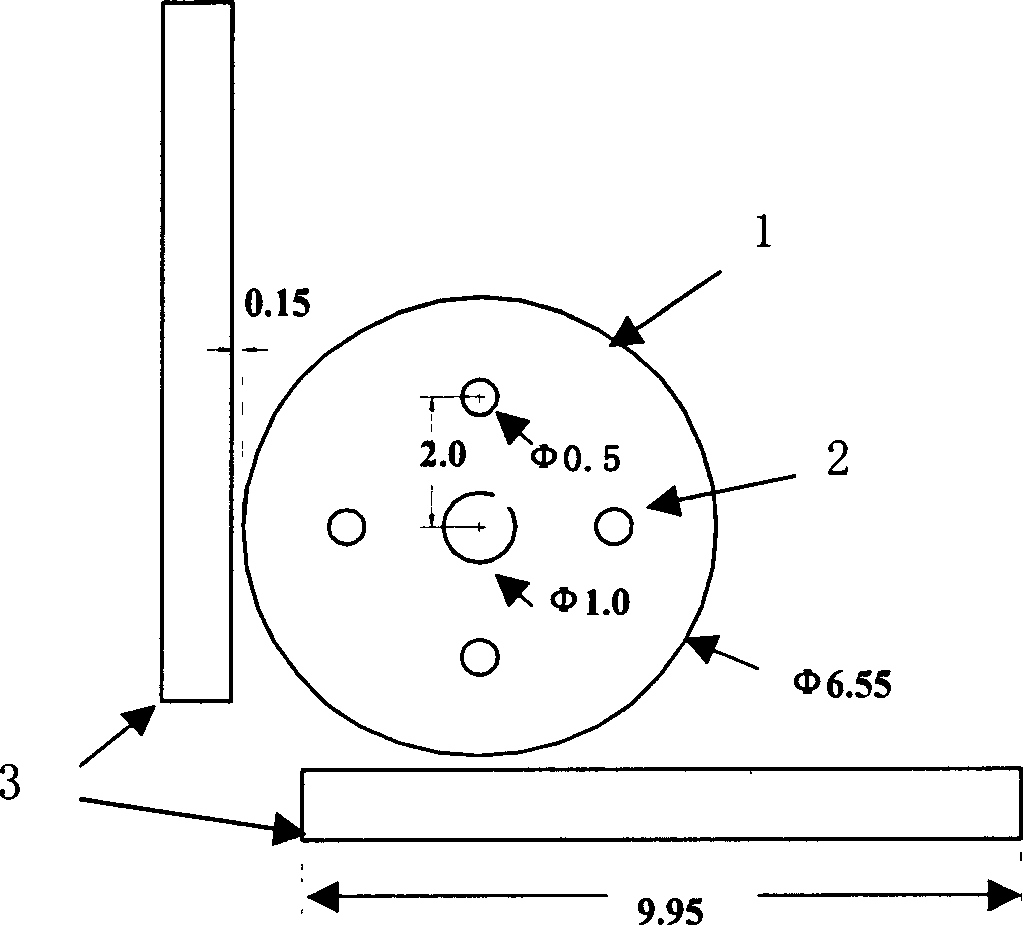

[0012] The high-power high-temperature superconducting miniaturized filter of the present invention has a periodic disk photonic bandgap structure (PBG), such as figure 1 shown. Four circular holes 2 are evenly distributed on a concentric circumferential line of the disc resonator 1, and the ratio of the radius of the circular holes 2 to the radius of the circular hole is greater than one-tenth, forming a photonic bandgap structure. The periodic circular hole 2 can realize two electromagnetic field existence modes, and the working mode is TM 010 . The disk resonator 1 is coupled with two mutually perpendicular feed lines 3 after corroding the circular hole 2 to form a disk filter. Due to the slow-wave characteristics of the photonic bandgap structure, that is, the wavelength of the electromagnetic waveguide passing through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com