Process for making and using a low beverage soluble iron content adsorbent and composition made thereby

A technology for alcoholic beverages and iron content, which is applied in the preparation of alcoholic beverages, biochemical equipment and methods, silicon compounds, etc., and can solve problems such as affecting the taste and shelf life of beer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

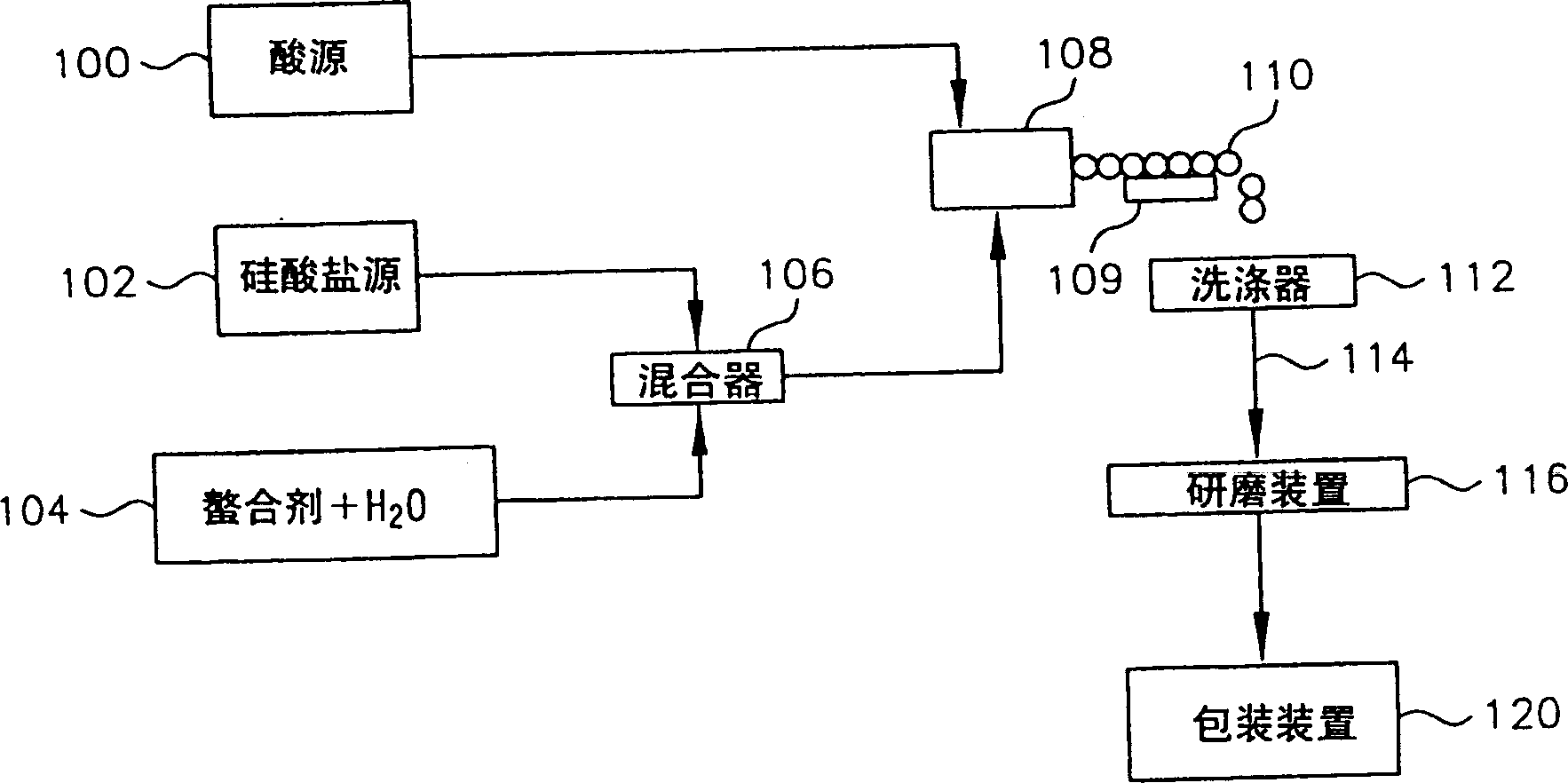

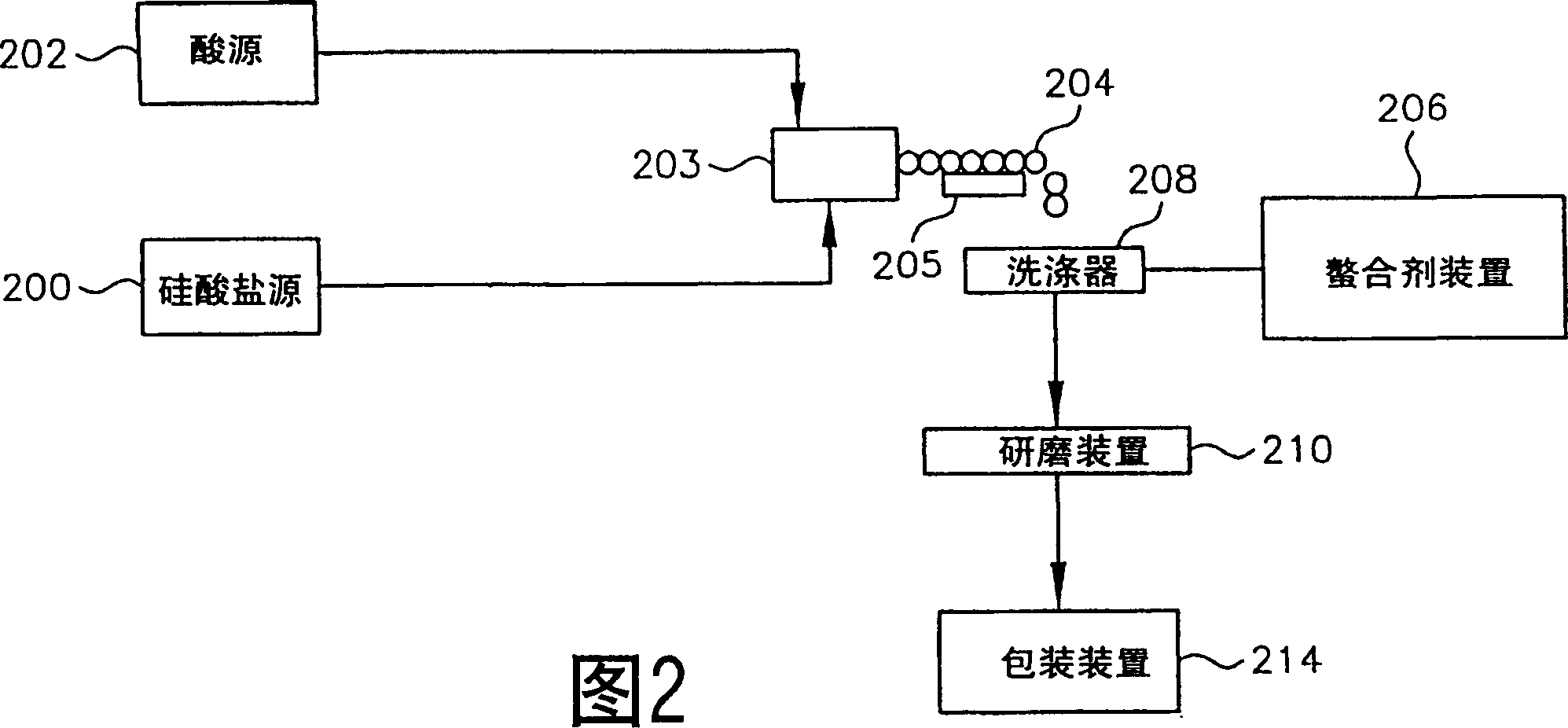

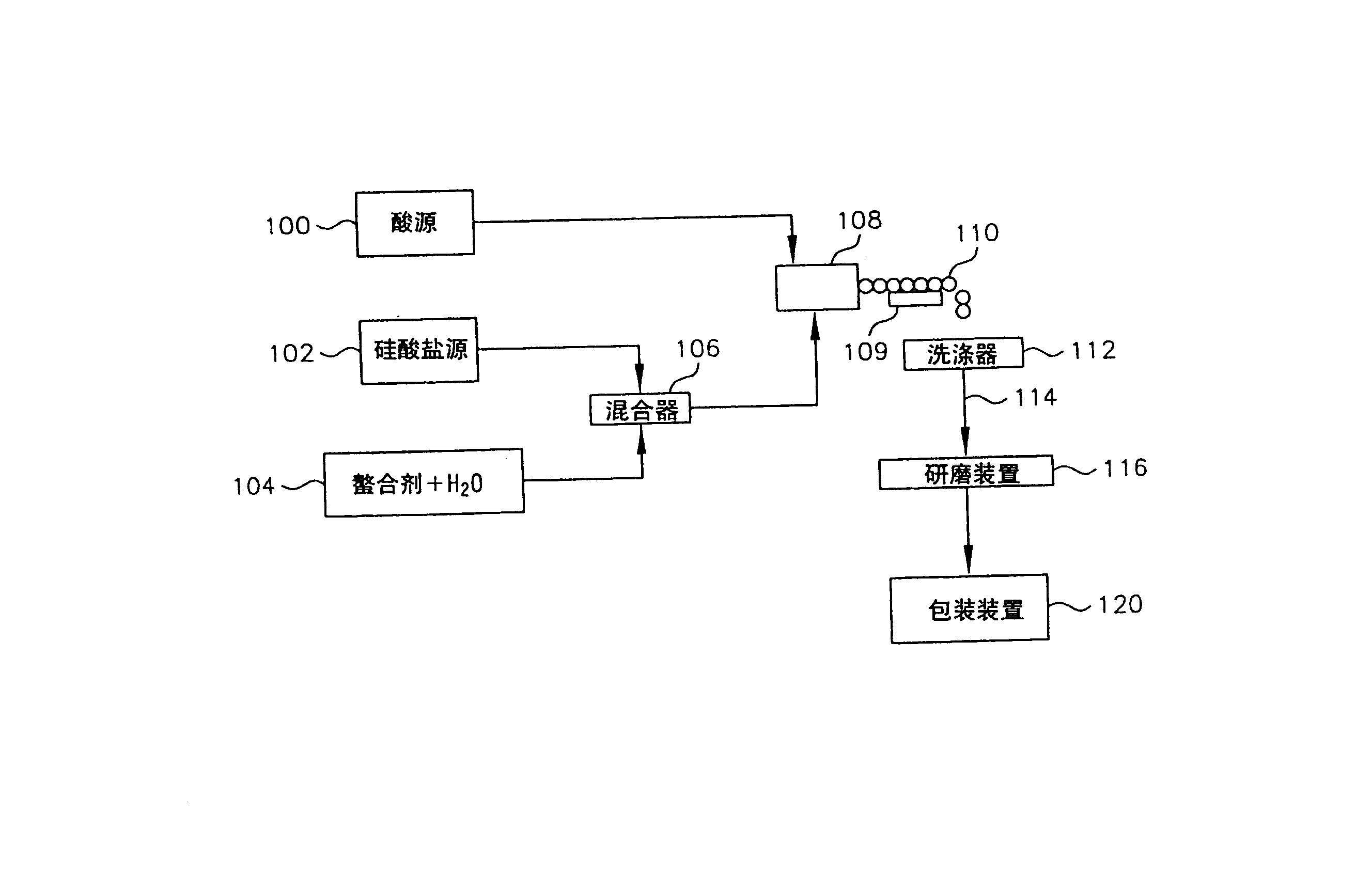

Method used

Image

Examples

Embodiment 1

[0034] In one embodiment of the method of making the product of the invention, STPP is dissolved in water and allowed to mix with sodium silicate at room temperature for 5 hours. The STPP-doped silicate mixture contained 0.1% by weight of STPP, based on sodium silicate. The concentration of the acid solution was 14.4% sulfuric acid and the temperature was about 72°F. The standard SiO of the silicate solution 2 :Na 2 The O weight ratio was 3.25, the solids content was 22%, and the temperature was about 72°F. Adjust the concentration and ratio of silicate and acid so that the hydrosol contains 10% SiO 2 , and make it possible to have 20% more acid than is required to neutralize the sodium present in the silicate solution. The hydrosol can gel in the container at 122°F. The gel time is several hours. The gel was then aged at 122[deg.]F and washed with acidified water, acidified with sulfuric acid. The pH of the acidified water used to remove sodium sulfate was 3.3. This s...

Embodiment 2

[0038] In another embodiment of the method of the present invention, the preparation method of the silica gel is the same as that of Embodiment 1 except that the concentration of STPP is increased. Based on sodium silicate, STPP in Example 2 was 0.15% by weight. Control Sample 2 was also prepared for comparison, using the same procedure as Sample 1, except STPP was not used in the control experiment.

Embodiment 3

[0040] In an example of the second embodiment used to make the adsorbent of the present invention, silica gel was prepared by neutralizing sodium silicate with sulfuric acid. The acid solution has a concentration of 41.8% H 2 SO 4 , a temperature of about 80°F. Standard SiO in Silicate Solutions 2 :Na 2 The O weight ratio was 3.2, the solids content was 31.4%, and the temperature was 80°F. Adjust the concentration and ratio of silicate and acid so that the hydrosol contains 18% SiO 2 , and allow for 20% more acid to neutralize the sodium present in the silicate solution. Preparation of STPP-doped acid aqueous solution Firstly, STPP was dissolved in water, the concentration of STPP based on water was 50 ppm, and then the pH value of the solution was adjusted to 3.4 by adding sulfuric acid. The ratio of gel to wash water is adjusted so that the total amount of STPP used is equal to 0.1% by weight, based on sodium silicate. This sample is referred to as Sample 3.

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com