Position regulator of non-contact supported fast rotary rotor, esp. spinning rotor

A technology for adjusting the position of the device and the rotor, which is applied in the processing of textile materials, electromechanical devices, textiles and papermaking, etc., can solve the problems of the device can not be compensated, the non-uniformity of the rotor material, etc., to achieve the effect of simple cost and reduced power reception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

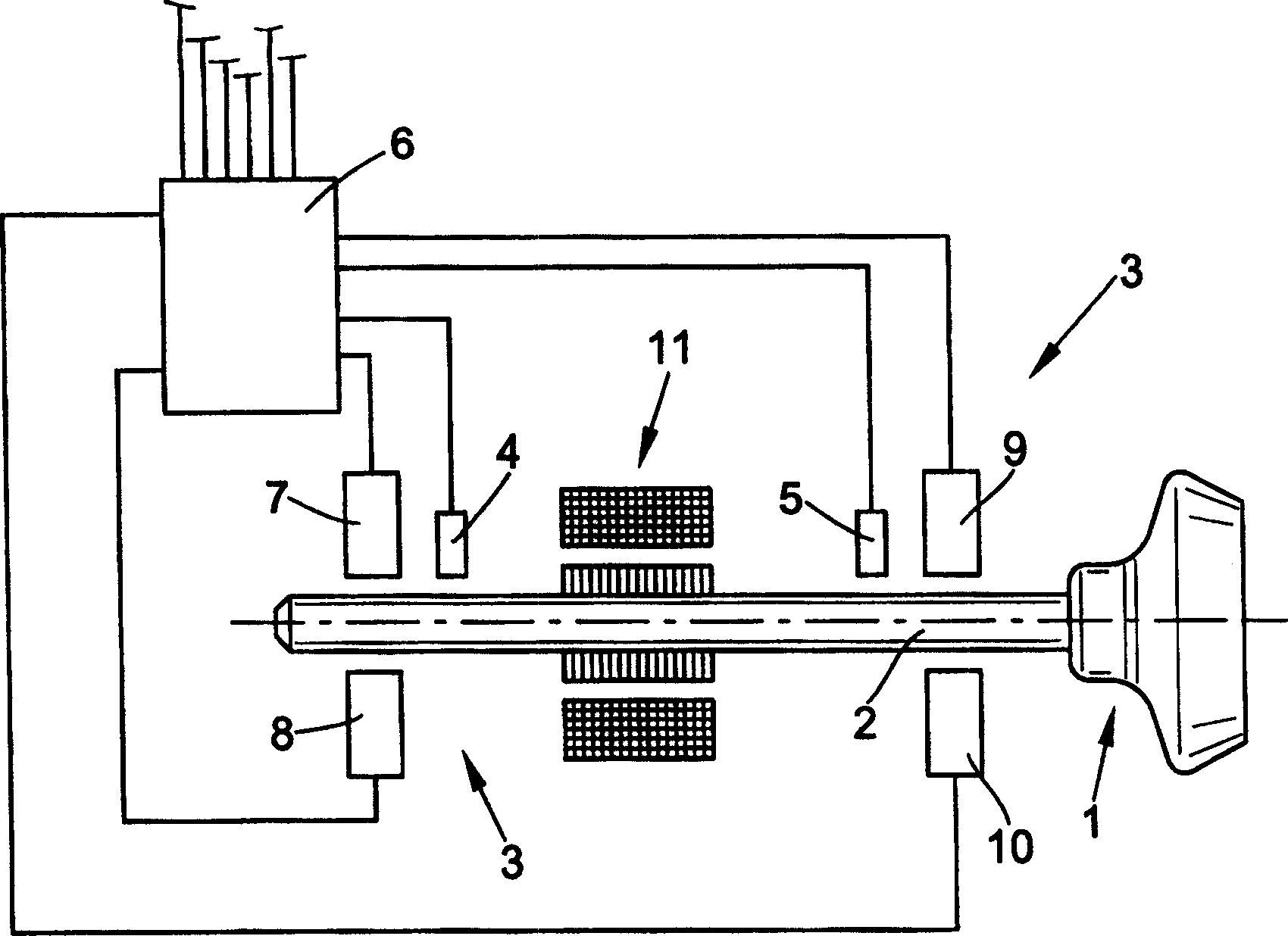

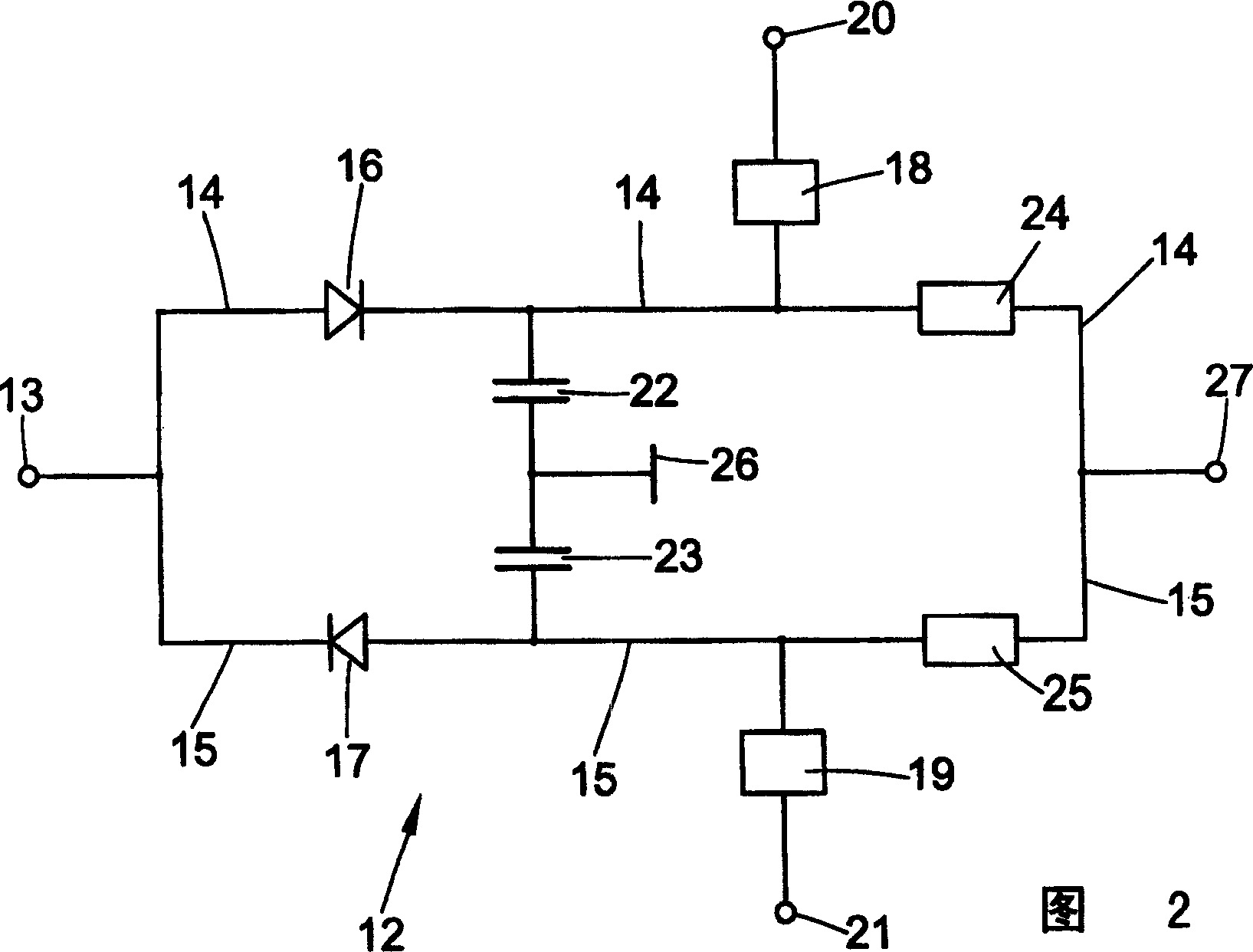

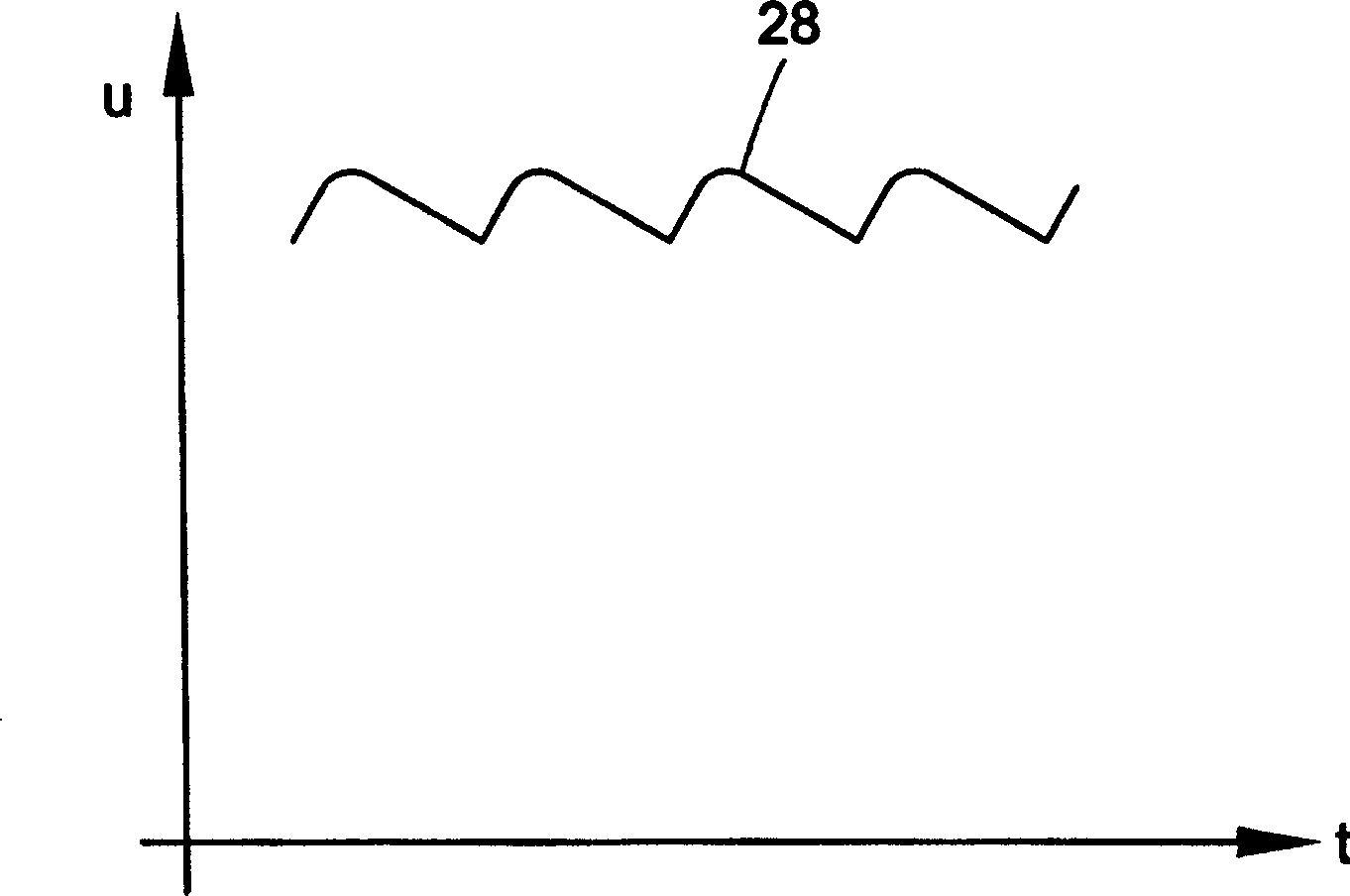

[0035] Will be attached figure 1 The textile rotor 1 shown above is supported on the rotor shaft 2 with magnetic bearings. The position of the rotor shaft 2 is detected by a sensor device having sensors 4, 5 by a method known per se. The sensor device continuously generates a detection signal, inputs the detected signal to the control device 6, and outputs an actuator signal from the control device. The actuator elements 7, 8, 9, 10 belonging to the sensors 4, 5 have magnetic coils and are used to hold the textile rotor 1 in the desired position. The driving device 11 gives the textile rotor 1 a rotational movement. In order to operate the actuator elements 7, 8, 9, 10, the control device 6 uses the control voltage U ST Load the actuator device. Accordingly, for reasons of simplification, the sensors and actuator elements that are not shown are installed at 90° offset from the sensors 4, 5 and actuator elements 7, 8, 9, 10 in the rotation direction of the textile rotor 1. For the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com