Microorganism strain and method for converting cephalosporin C into deacetylate cephalosporin C by using same

A technology for deacetylating cephalosporins and cephalosporins, which is applied in the directions of fungi and fermentation, can solve the problems of low yield, high cost, unsuitable for industrial-scale production and the like, and achieves the effect of simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

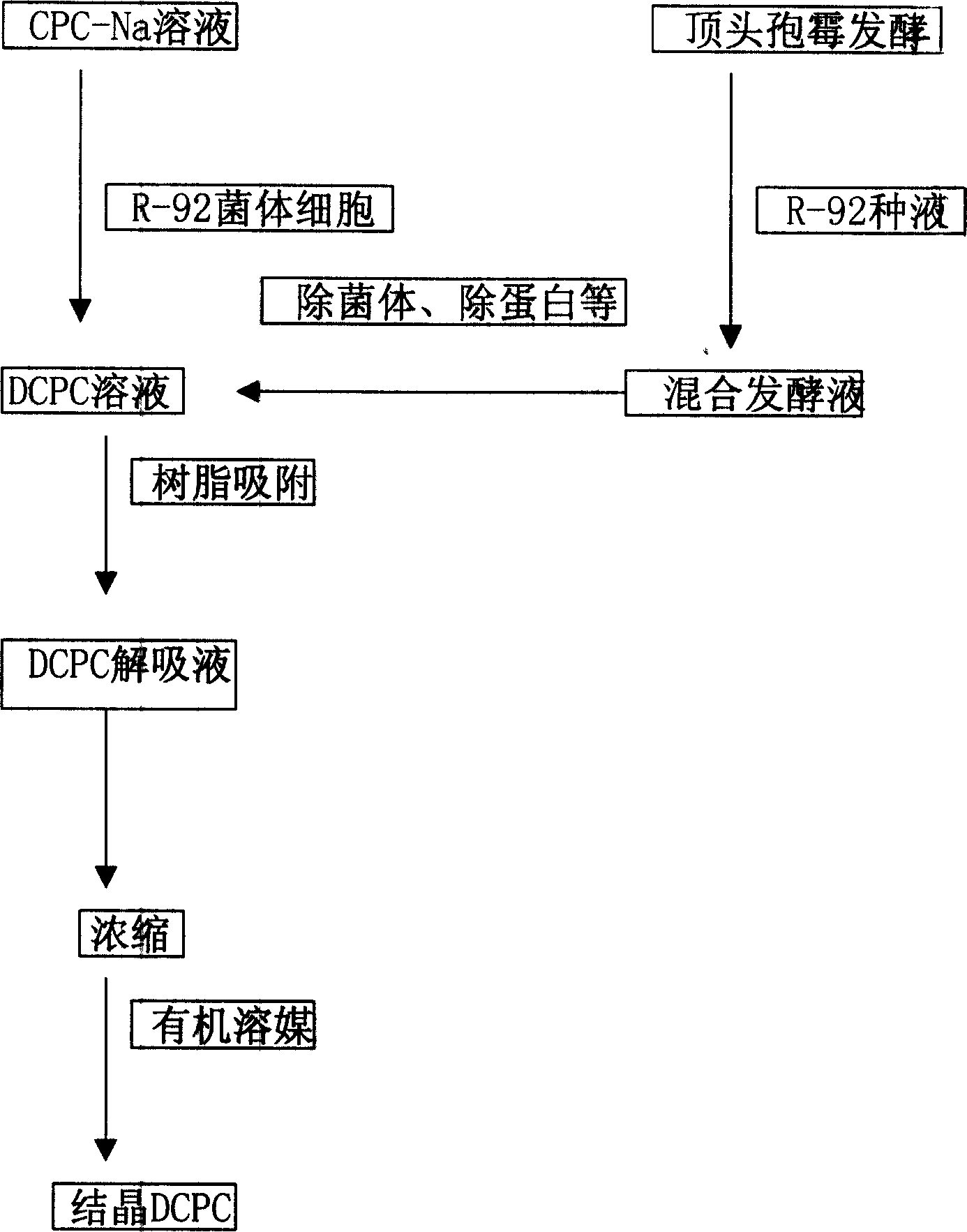

[0061] Example 1: R-92 bacterium culture medium: glucose 0.5%, peptone 1.2%, beef extract 0.1%, magnesium sulfate 0.05%, all the other are distilled water, adjust pH5.0, every 250ml Erlenmeyer flask is filled with 10ml prepared medium, Steam sterilize at 115°C for 30 minutes, inoculate R-92 strains, culture at 25-27°C with shaking at 100r / min for 72 hours, and centrifuge the culture solution at 4000r / min to obtain R-92 wet bacteria.

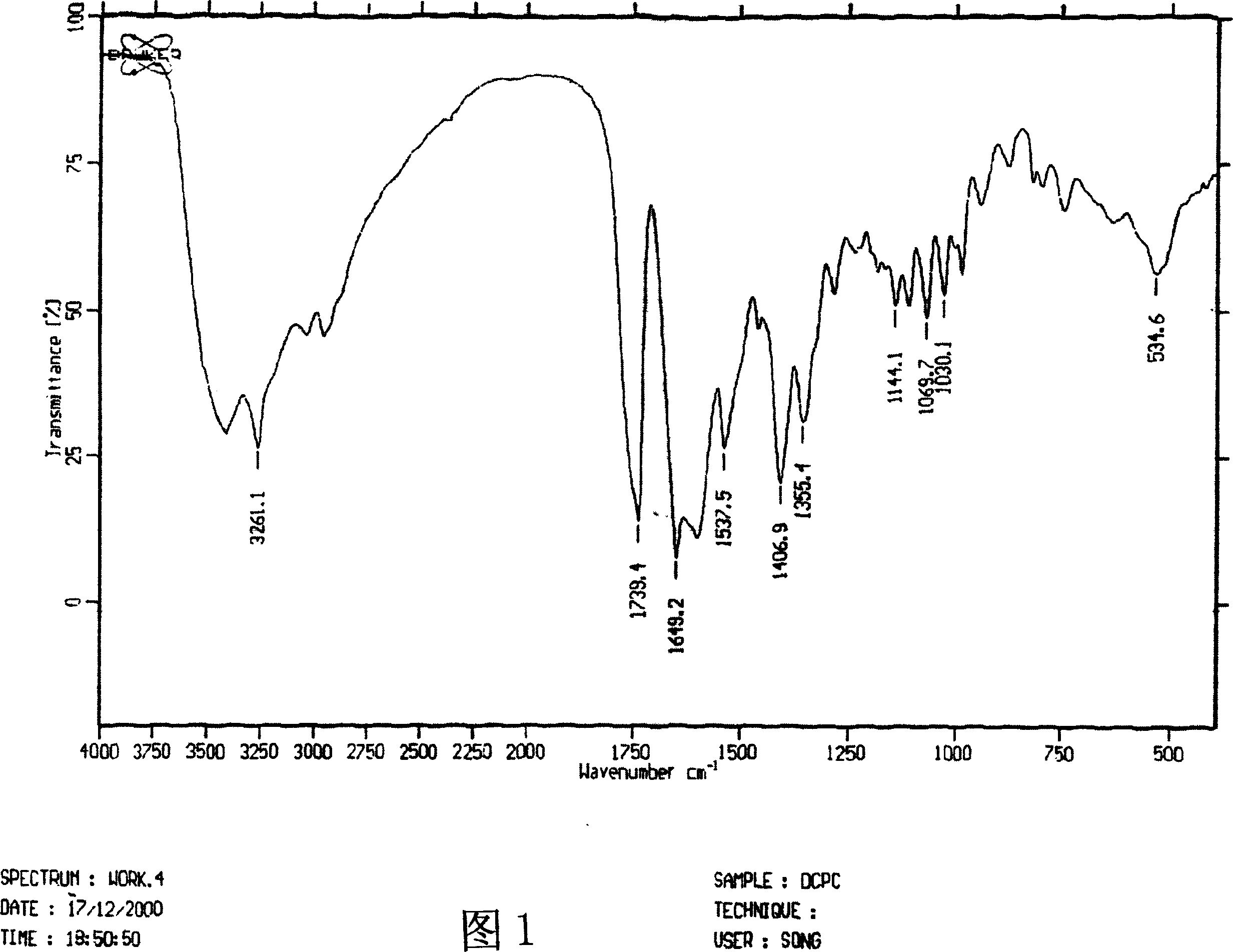

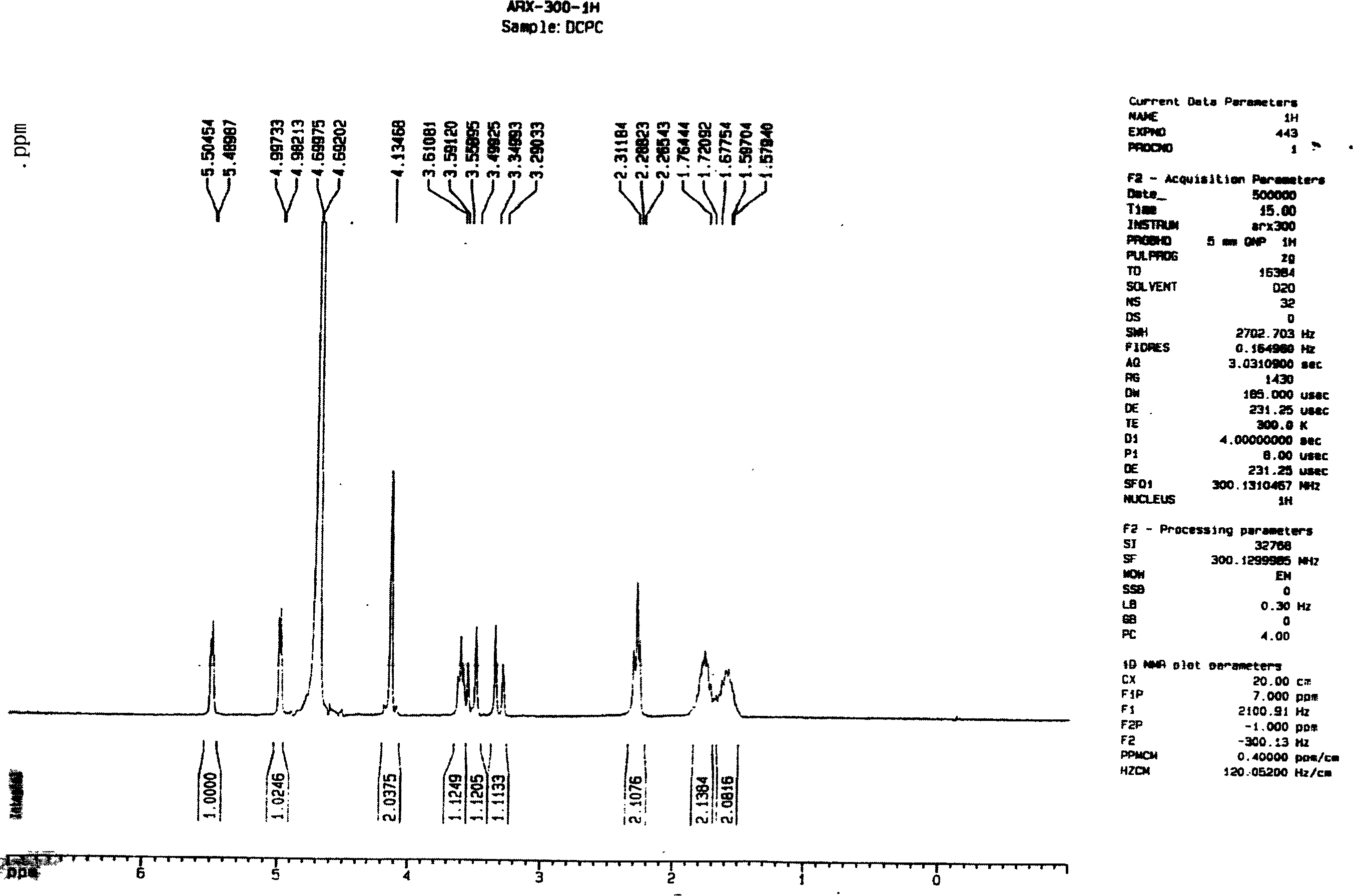

[0062] 0.5 g of CPCNa was dissolved in 50 ml of buffer solution of pH 5.8, 0.5 g of the wet thalline prepared above was added, transformed at 27° C. and 200 r / min for 38 hours, and the conversion rate was determined by HPLC to be 80%, and the transformed liquid was centrifuged at 4000 r / min. The centrifugate was filtered with a 0.8 μm membrane, concentrated under reduced pressure at 40°C to 1 / 5 of the original volume, added 4 times the amount of ethanol, stirred for crystallization, suction filtered, and dried to obtain 0.22 g of a light yellow po...

example 2

[0063] Example 2: Bacteria culture medium: 1% glucose, 1% peptone, 0.3% beef extract, 0.02% magnesium sulfate, and the rest are distilled water, adjust the pH of the medium to 6.0, fill 50ml of medium in every 250ml Erlenmeyer flask, and steam out at 115°C Bacteria were incubated for 30 minutes, inserted into R-92, shaken at 240r / min, 30°C for 48 hours, and centrifuged to obtain the bacteria.

[0064] CPCNa 1.5g was dissolved in 50ml pH5.8 phosphate buffer, 2g of wet bacteria was added, 28-30°C, 200r / min shaking transformation, HPLC determined that the transformation was completed in 28 hours, and the transformation rate was 100%. The transformation solution was centrifuged at 4000r / min to remove bacteria, the centrifugate was filtered through a 0.8μm membrane, concentrated under reduced pressure at 40°C to 1 / 3 of the original volume, 4 times the volume of ethanol was added, stirred to crystallize, suction filtered, and dried to obtain 1.1g of a yellowish powder.

example 3

[0065] Example 3: Same as Example 2, the difference is that the pH of the transformation solution is 4.5, and the transformation time is 50 hours. The conversion rate measured by HPLC is 49%. After concentration and crystallization, 0.36 g of DCPC solid was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com