Air inlet structure for engine

An air intake structure and engine technology, applied in the direction of intake muffler, fuel air intake, combined air filter and muffler, etc., can solve the loss of layout flexibility, ensure that the installation location is easy to add restrictions, Large-scale assembly components and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the air intake structure of the engine according to the embodiment of the present invention will be described using the attached drawings.

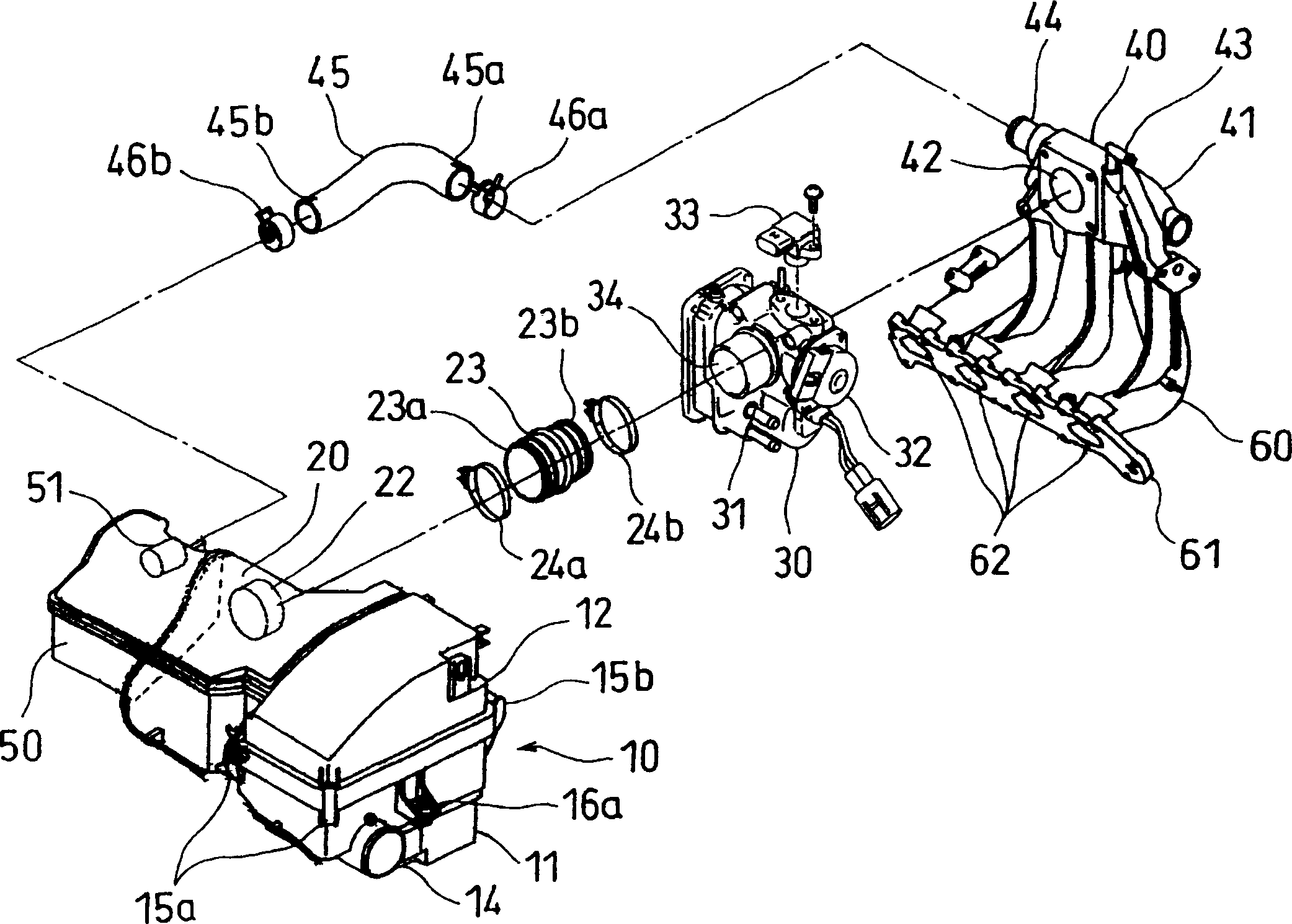

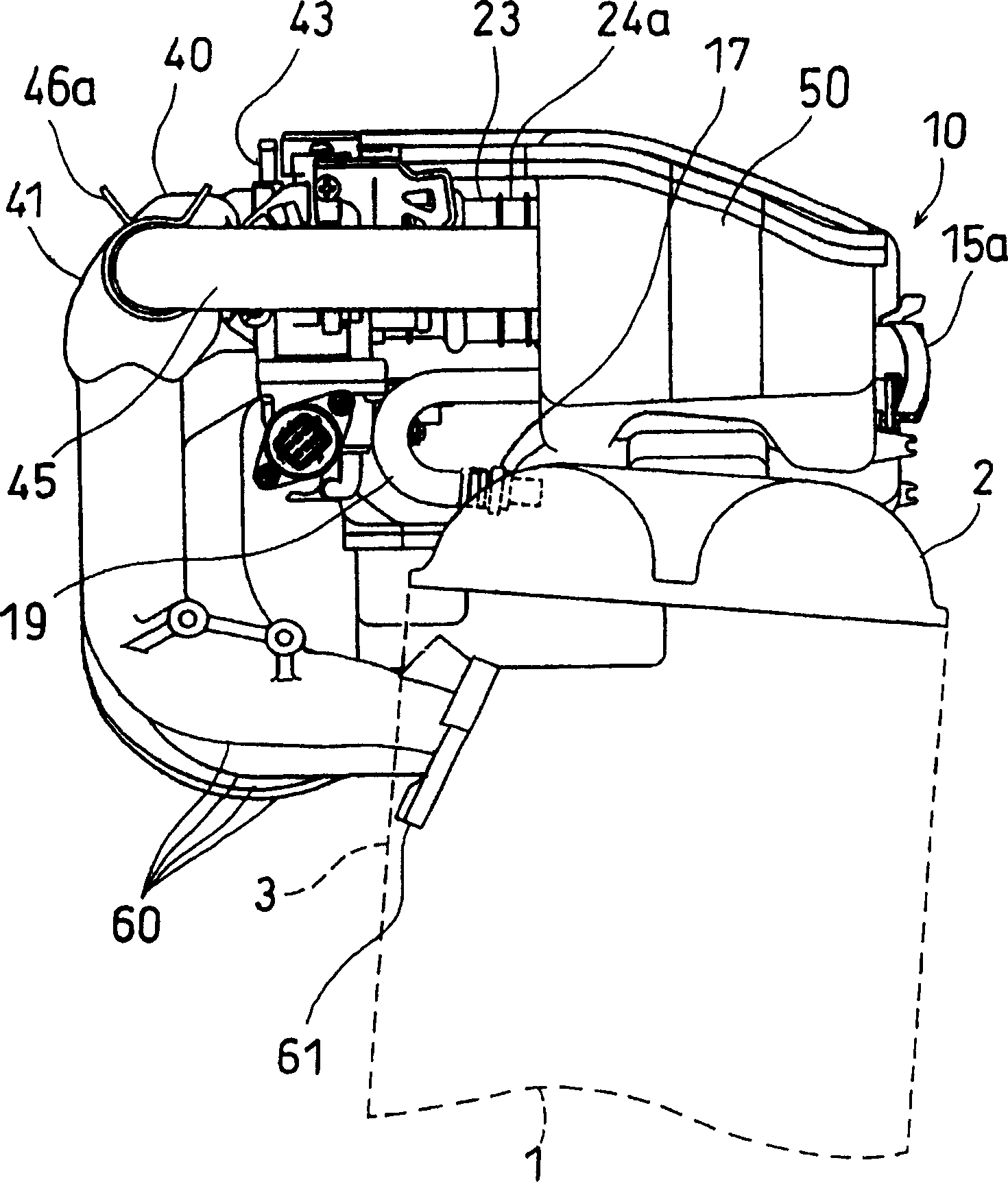

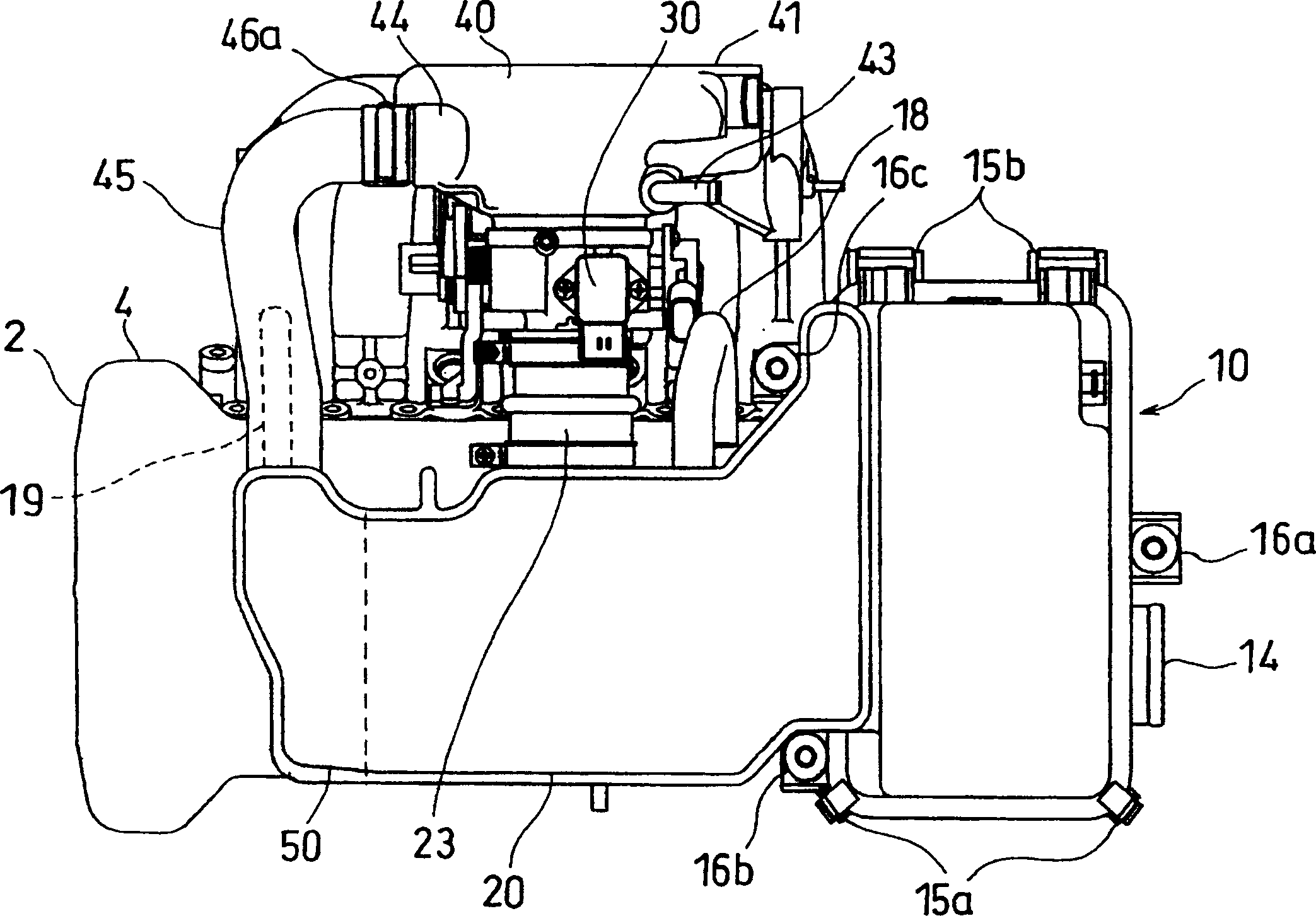

[0028] figure 1 It is a schematic diagram showing the intake structure of the engine according to the embodiment of the present invention. As shown in the figure, the air filter 10, the throttle body 30, the surge tank 40 and the intake branch pipe 60 are connected to form an air intake system for sucking air into the engine from the outside of the vehicle. At this time, as known to those skilled in the art, the air filter 10 is used to prevent dust in the air from entering the engine to accelerate wear, and to reduce intake noise. In addition, the engine output is controlled by controlling the amount of intake air by the throttle body 30 . In addition, the surge tank 40 functions as a collection part connecting the throttle body 30 and the intake branch pipe 60 , and prevents interference of each cylinder while prev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com