Refractory plug or brick for injecting gas into molten metal and its production method

A technology of molten metal and refractory materials, applied in the manufacture of converters, etc., can solve the problem of high cost, achieve the effect of preventing gas leakage and small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

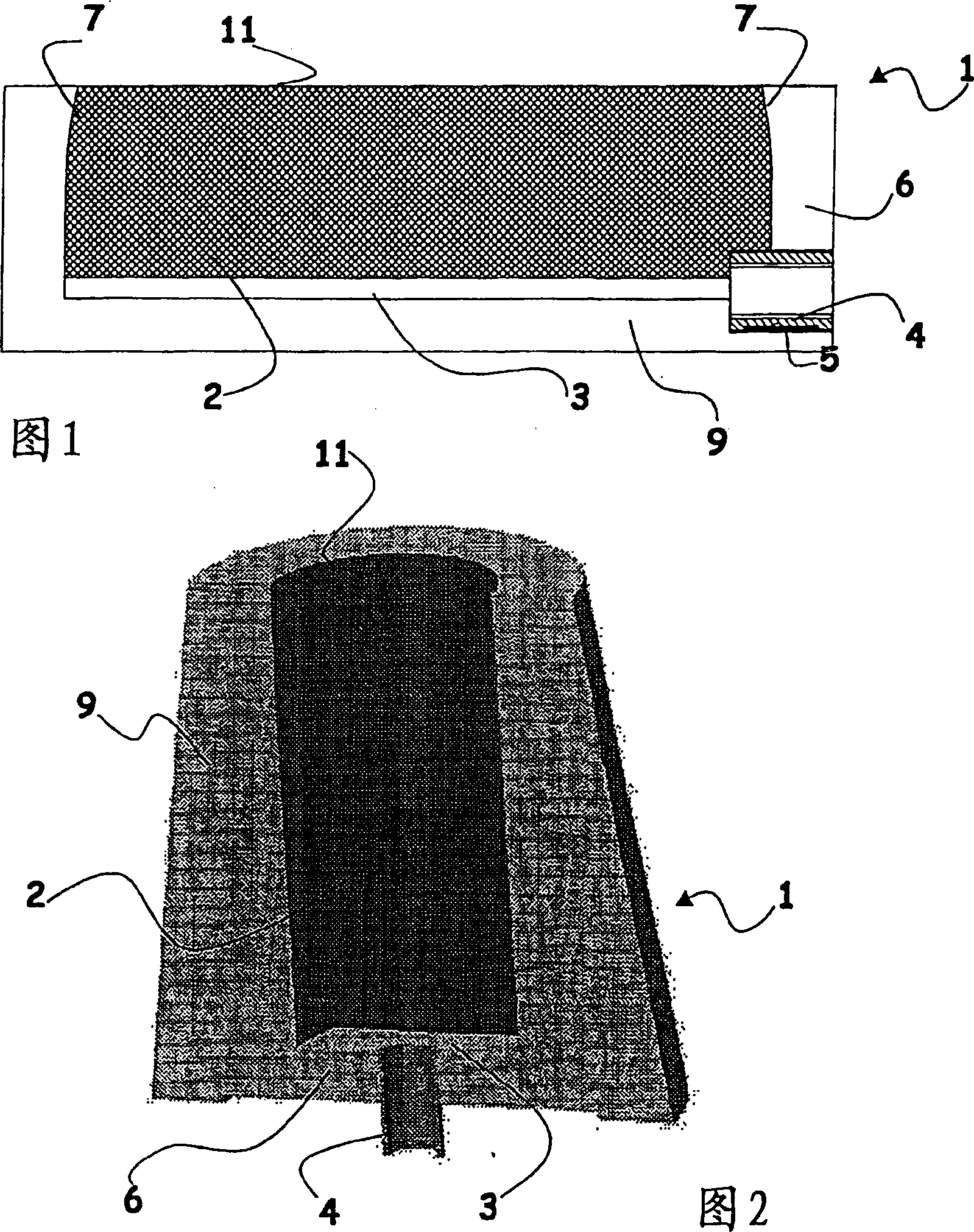

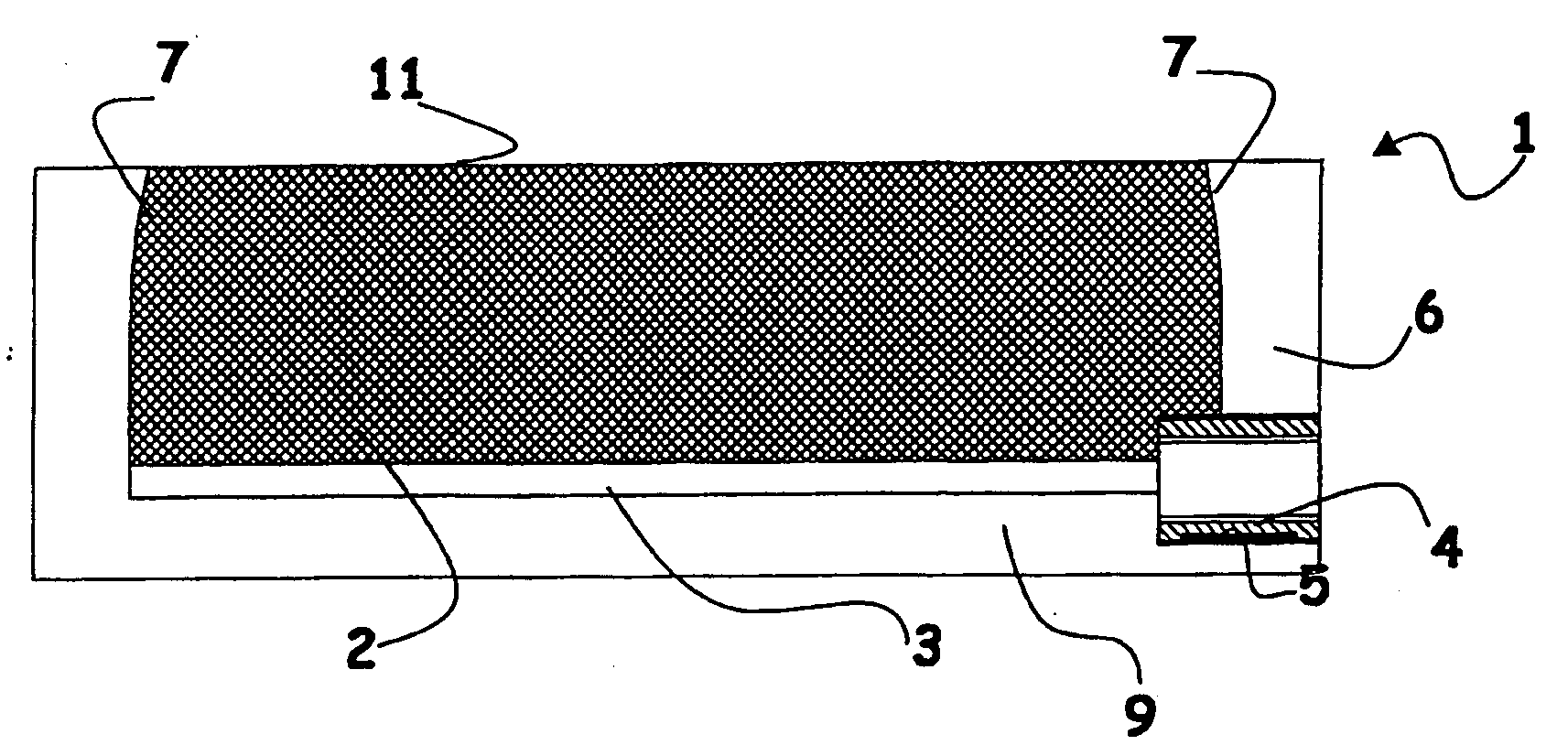

[0041] Both figures show a plug or brick (1) for injecting gas into molten metal through a molten metal contact surface (11) comprising a body of porous refractory material (2) in addition to The molten metal contact surface (11) is substantially surrounded by a non-porous body (9). Figures 1 and 2 also show gas guiding means comprising metal or refractory conduits (4) extending through the wall (6) of the plug or brick and connected to the plenum (3). This conduit (4) is usually held in place by ordinary sealing cement or mortar (5).

[0042] Preferably, during the pressing step, a tapering portion (7) is produced towards the molten metal contact surface, as shown in FIG. 1 . During the pressing action, the tapering effect is produced by deforming the porous body into the non-porous medium at the vertical sides of the pressing die. The tapered shape also prevents the porous body (2) from being largely exfoliated by forming bonds.

[0043] According to an embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com